44

Auto-levelling system

The 686PT is fitted with an automatic sheet levelling system. An optical sensor directs a beam of infrared

light across the machine. The system comprises of a transmitter and receiver. When the beam is broken air

is pumped into the machine cabinet under the plastic lifting it until beam transmission is re-established. The

optical sensors are located under the top-frame at the sides.

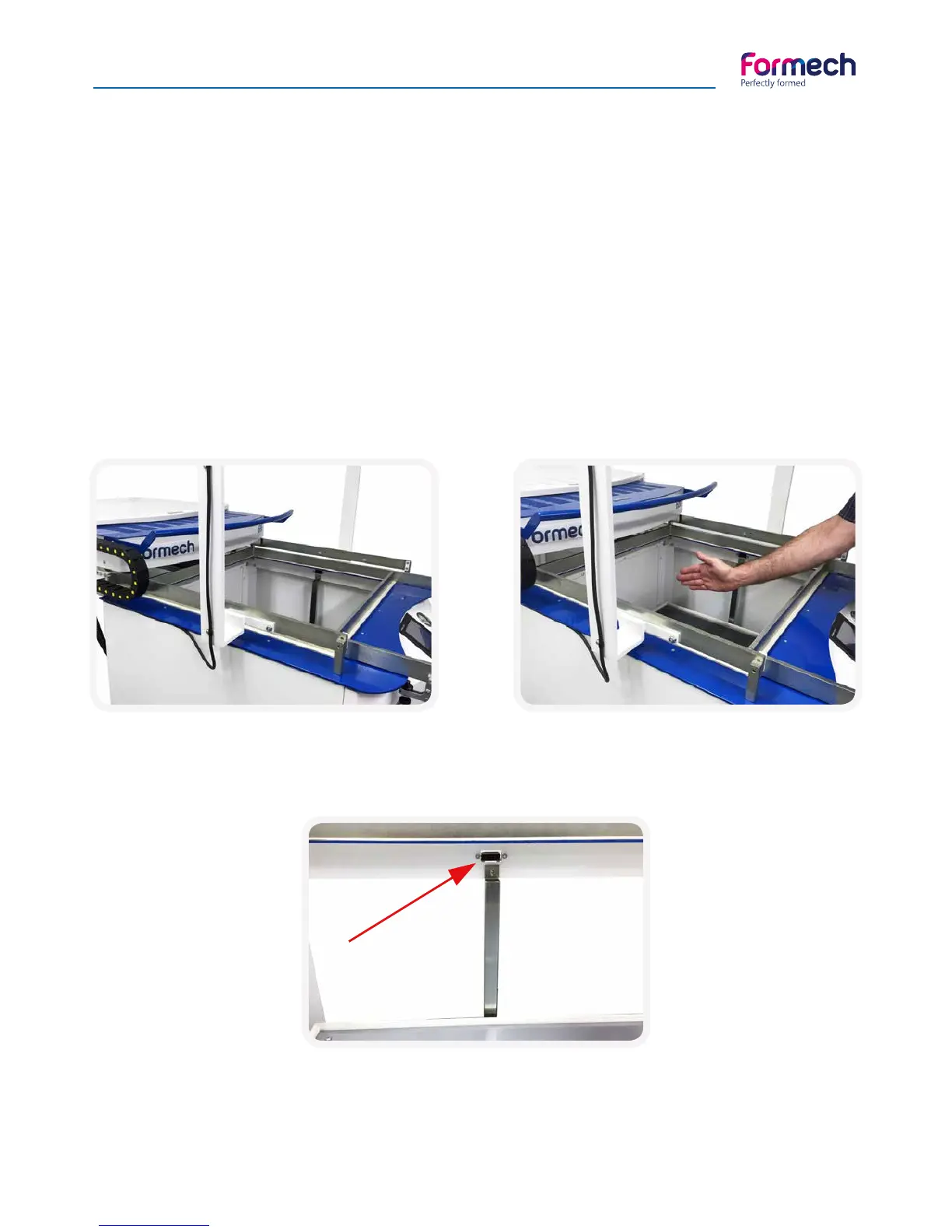

It is important the transmitter beam is directed at the receiver. Adjustment may be carried out by slightly

bending the sensor mounting plate to ensure alignment. The receiver LED’s will show red when broken or

misaligned and green when OK.

For transparent materials it is possible that the sensors will not operate correctly as the infrared will pass

through the material. In such cases an optical attenuator is available that will create a narrow beam and

reduce the sensitivity. Contact Formech if an attenuator is required.

How to check the auto-level sensor

Fault Diagnostics / Maintenance

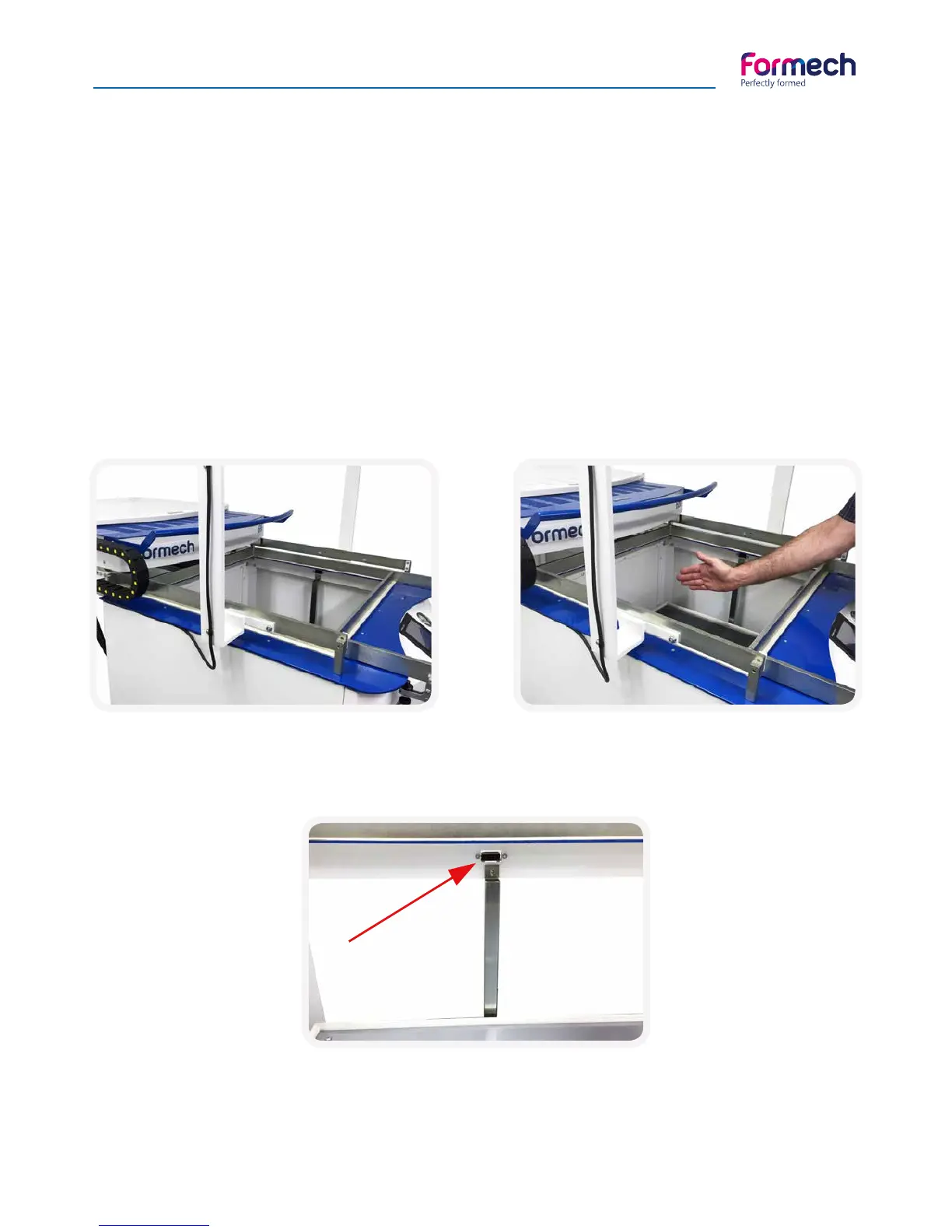

Bring the clamping frame down and the heater

slightly forward from the back position to enable

the auto-level.

Activate the auto-level on the touch-screen, place

your hand in the center of the aperture and move

it up & down until you hear the air valve turning

on and off.

If the auto-level air valve is constantly blowing it may be due to misalignment or an accumulation of dust on

the front of the sensor. Check the alignment and / or inspect for lens cleanliness and check again. If the air

valve does not function with the test above, inspect the device lenses for heat damage and also refer to the

state of the indicators on the receiver. If it is still not working, please contact Formech.

Loading...

Loading...