45

Fault Diagnostics / Maintenance

Vacuum

Warning: never oil any part of the vacuum pump. It is designed to run dry and could be

severely damaged by lubrication.

The vacuum circuit requires very little maintenance. The inlet filter is mounted on top of the vacuum pump

situated under the table of the machine. Unclip the top cover of the filter box. The paper cartridge filter will

prevent small particles and dust from entering the vacuum pump. This filter should be inspected periodically

and blown out if dirty or replace if in poor condition. Do not run the machine without this filter.

Worn or damaged seals around the perimeter of the table may cause loss of vacuum. These are classed as a

consumable part and require replacement after some time. To replace seals follow the procedure relating to

Clamp & Table seals in this section.

Other causes of vacuum loss are loose or damaged flexible pipes or fittings, blocked filters or build up of

contamination in the vacuum valves. Valves should be dismantled, cleaned and lubricated or replaced.

Lubricants or other liquid may cause irreparable damage to the pump if introduced into the vacuum circuit.

Vacuum system

If the vacuum appears to be weak or non-existent check the following:

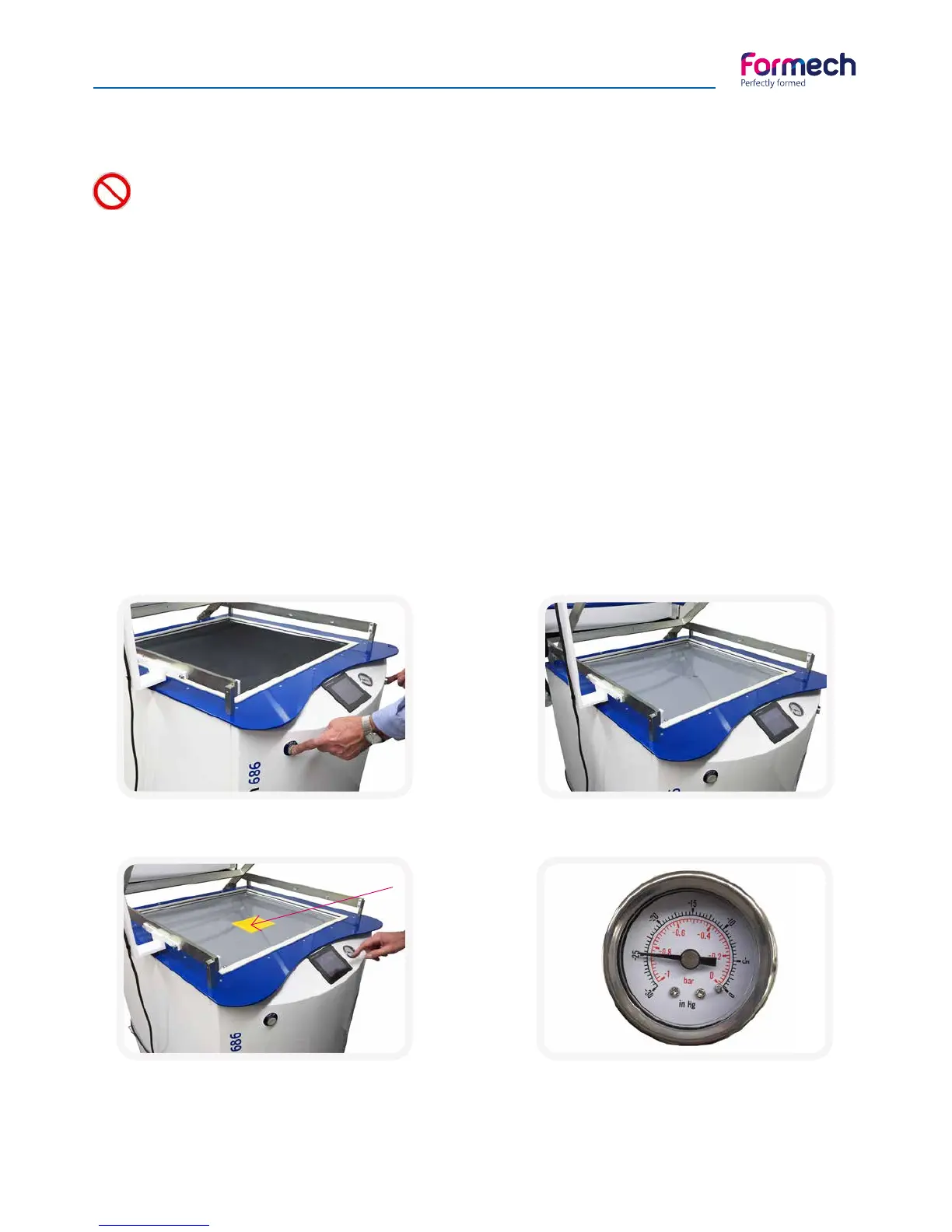

Raise the table up. Take off the table mesh.

Put a piece of plastic or the palm of your

hand on top of the vacuum hole. Activate

the vacuum and check the reading on

your vacuum gauge.

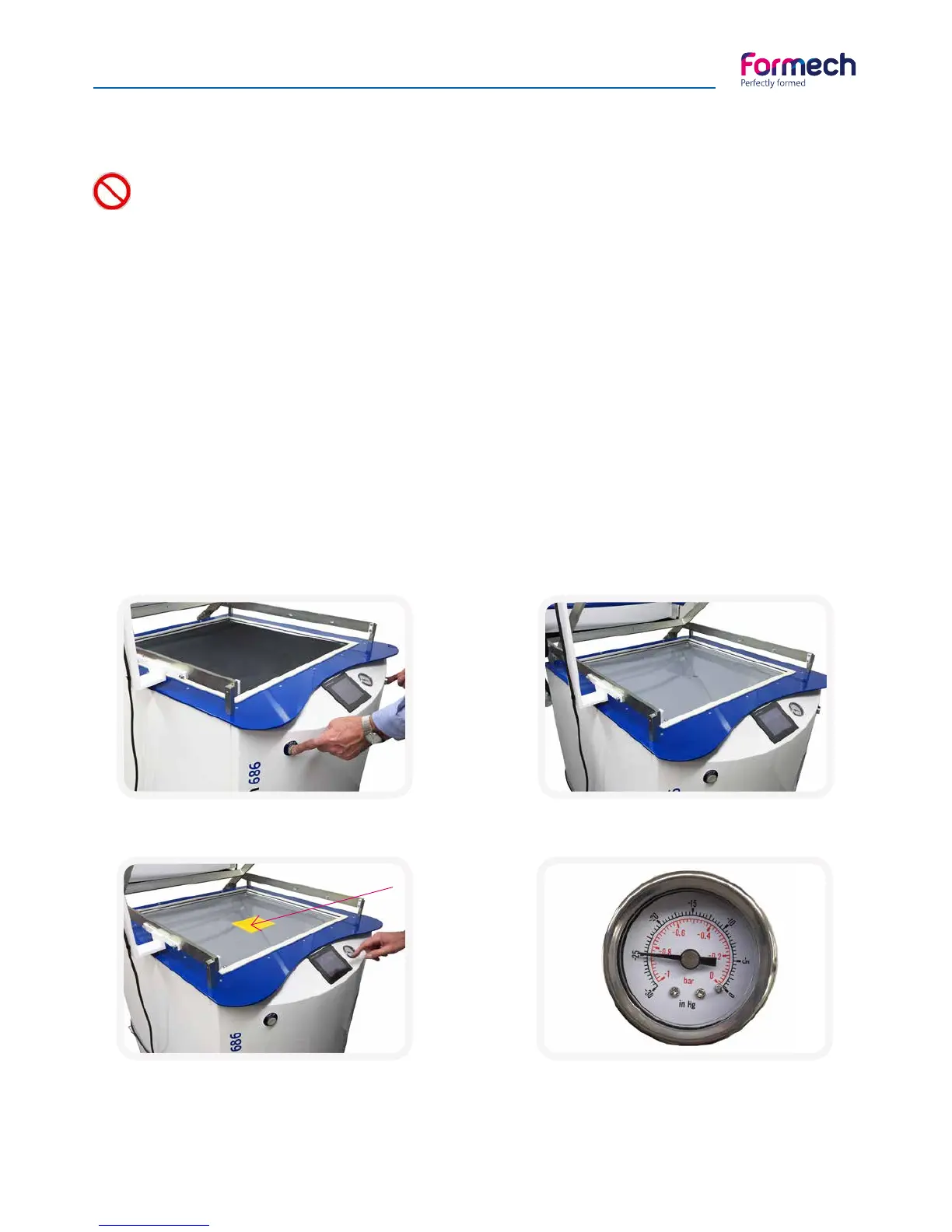

If the vacuum gauge reads 25”Hg or higher,

that is normal. A lower reading indicates

poor vacuum where attention is required

(see following page).

Loading...

Loading...