Metering

17

4.6 Positioning and metering a letter

Caution! By simple preventive measures and spe-

cial care when positioning letters, you can avoid

gaps in the imprint, tearing the ribbon and damaging

the thermal print head:

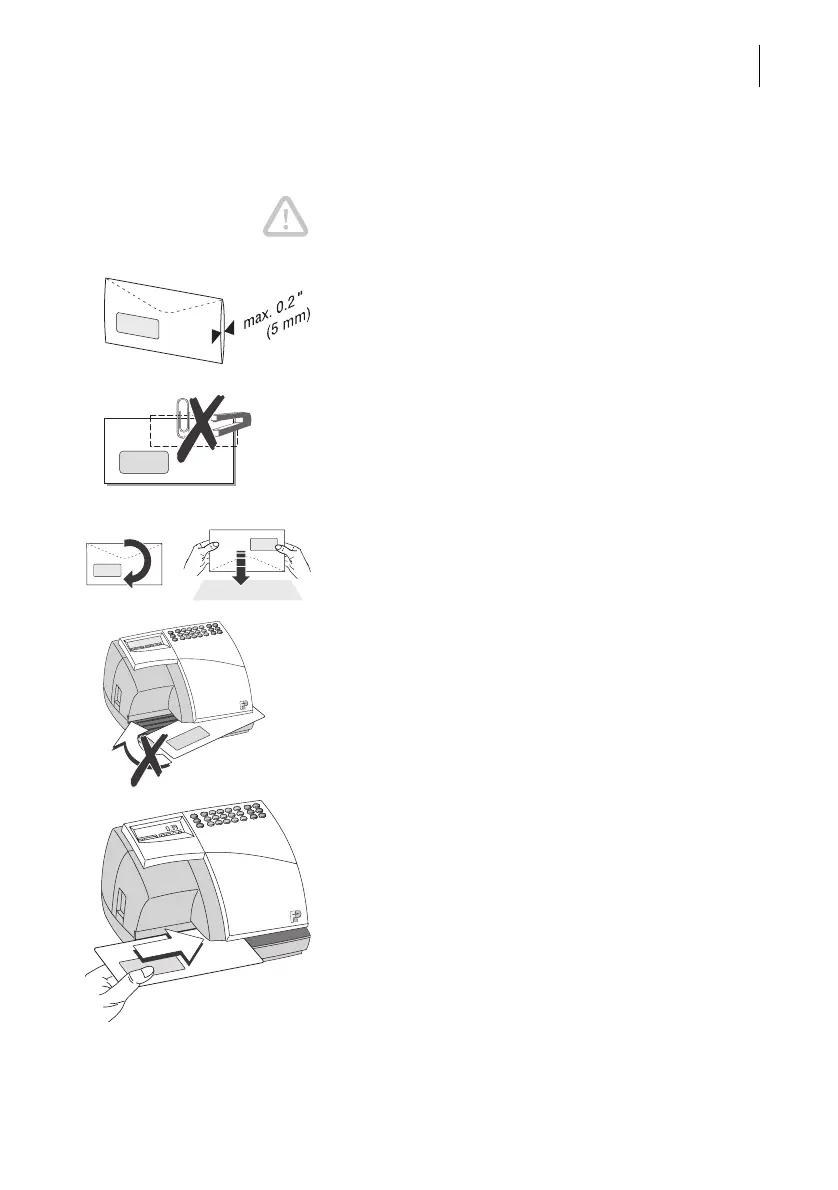

– You can meter letters up to a thickness of 0.2"

(5 mm). The difference in thickness in the printing

area in letters containing several sheets can lead

to an irregular imprint. In this case, meter the emp-

ty envelope or use FP labels.

– Use envelopes with as smooth a surface as

possible. This gives optimum imprint quality.

– Make sure you remove all staples and paper clips

from the area around the imprint.

– Before imprinting, knock the upper edge of the

envelopes against a smooth underlay. By aligning

the content of the letter with the upper edge of the

envelope you get an even surface to achieve bet-

ter meter imprints.

– During metering, it is best to let go of normal for-

mat letters (e.g. Commercial #6¾, #10).

Give large envelopes (e.g. #14) a little support.

– Under no circumstances should you attempt to

straighten the envelope whilst it is being printed.

How to feed a letter

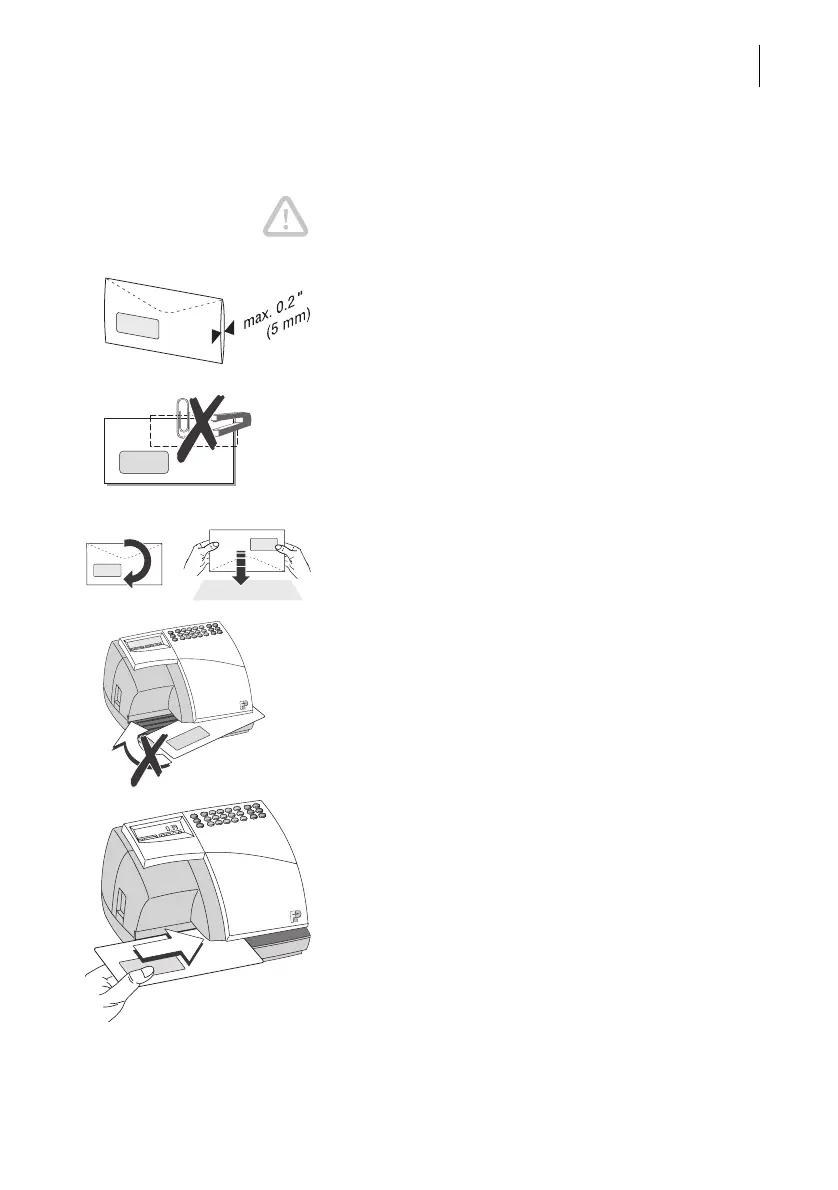

• Place the letter on the letter receiving tray:

– The side to be printed facing upwards, the

address field visible.

– The top edge must be flush with the letter guide.

• Push in the letter in the direction of the arrow until

the Optimail grips the letter.

As soon as the mail sensor detects a letter, a roller

presses the letter against the ribbon and print head

– the printing starts. The imprinted letter is ejected to

the right.

Loading...

Loading...