5

Fig. 5a Functional sequence in special 4-step mode - Variant II

I

S

I

H

I

t

I

E

I

H

Start of cycle

Gas pre-flow time

Current rise via up-slope

Gas post-flow time

End of welding

Welding with pre-set

lowering current

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

Current drop via

down-slope

Welding with pre-set

main current I

H

Crater-fill current I

E

I

E

Current drop via

down-slope

Current rise via up-slope

Pull back torch trigger and hold it down

Release the torch trigger

Release the torch trigger

Pull back torch trigger and hold it down

Release the torch trigger

briefly press the torch trigger

Pull back torch trigger and hold it down

Diagram showing intermediate lowering

Push trigger forward and hold it

Release the torch trigger

Release the torch trigger

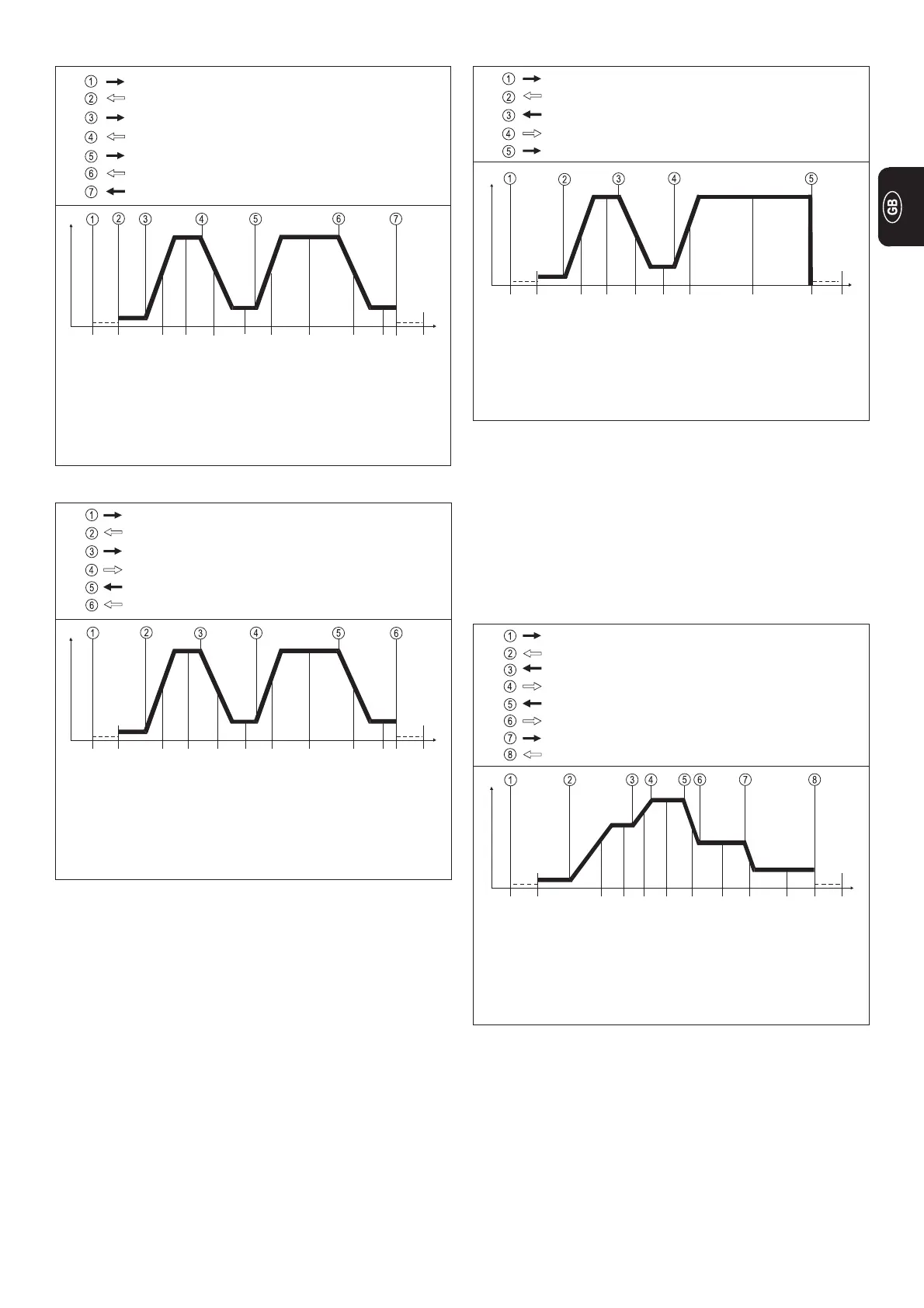

Fig. 5b Functional sequence in special 4-step operating mode - Variant III

Pull back torch trigger and hold it down

I

S

I

H

I

E

I

t

Pull back torch trigger and hold it down

Release the torch trigger

I

E

I

H

Start of cycle

Gas pre-flow time

Current rise via up-slope

Current drop via

down-slope

Gas post-flow time

End of welding

Crater-fill current I

E

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

Current rise via up-slope

Current drop via

down-slope

Welding with pre-set

main current I

H

Crater-fill current I

E

Diagram showing intermediate lowering

Push trigger forward and hold it

Release the torch trigger

Fig. 5c Functional sequence in special 4-step mode - Variant IV

Pull back torch trigger and hold it down

I

S

I

H

I

E

I

t

Pull back torch trigger and hold it down

Release the torch trigger

I

H

Start of cycle

Gas pre-flow time

Current rise via up-

slope

Current drop via

down-slope

Gas post-flow time

End of welding

Crater-fill current

I

E

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

Current rise via up-

slope

Welding with pre-set

main current I

H

Start of cycle

Gas pre-flow time

Current rise via up-slope

Current drop via

down-slope

Gas post-flow time

End of welding

Crater-fill current I

E

Pull back torch trigger and hold it down

Release the torch trigger

Release the torch trigger

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

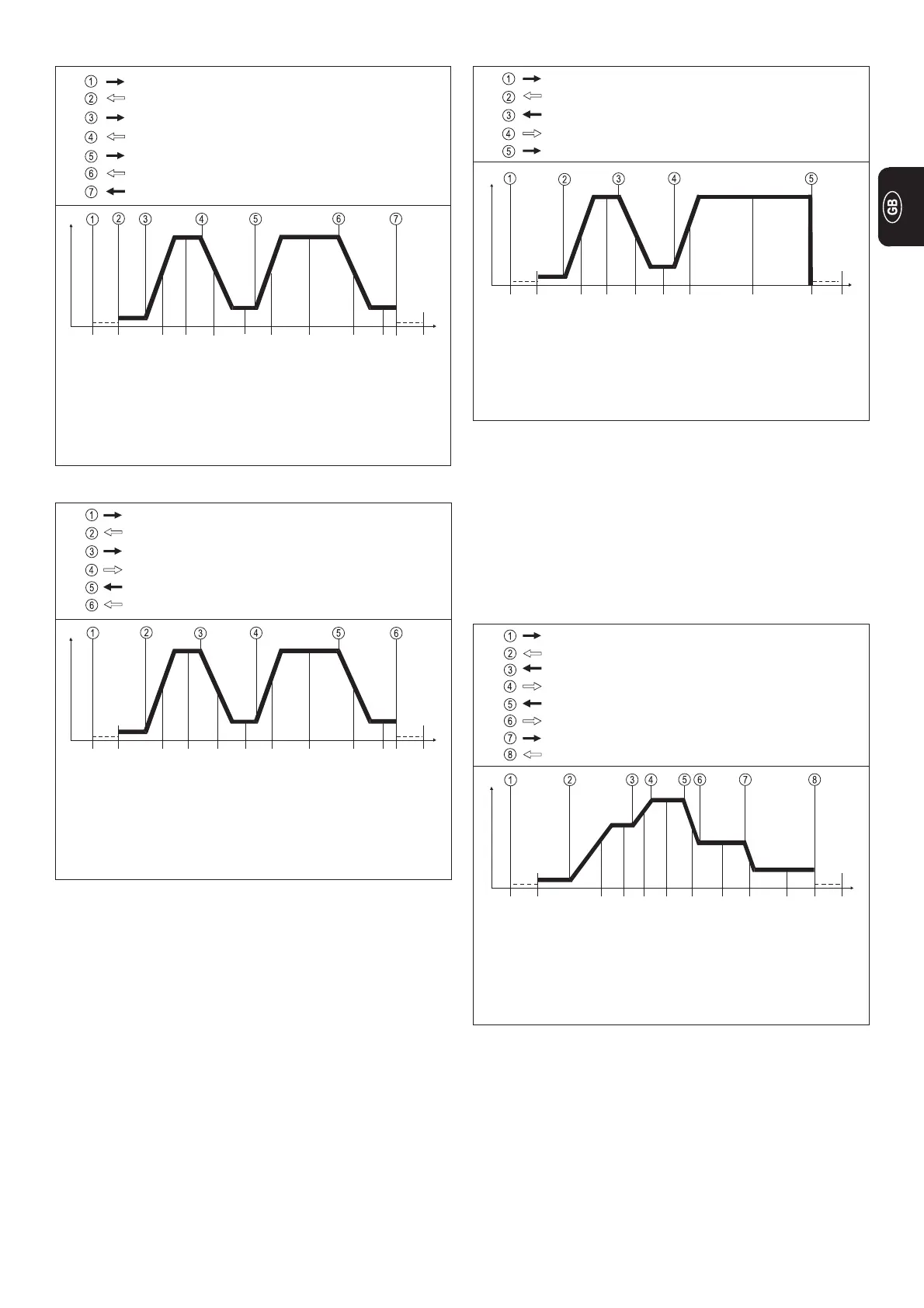

Fig 5d Functional sequence in special 4-step mode - Variant V

Push trigger forward and hold it

I

S

I

H

I

E

I

t

Current-rise while trigger is

pushed forward

Current-drop while trigger is

pushed forward

Welding with decreased

main current I

H

Push trigger forward and hold it

Release the torch trigger

Pull back torch trigger and hold it down

Release the torch trigger

Welding with increased

main current I

H

Variante V (Fig. 5d) allows the welder to raise and lower the

welding current without an Up/Down torch.

The longer the torch-trigger rocker switch is pushed forward during

welding, the more the welding current is increased (up to maximum).

After the welder releases the torch trigger, the welding current

remains constant. The longer the torch trigger is pushed forward

once again, the further the welding current is reduced.

Diagram showing intermediate lowering

Loading...

Loading...