6

Start of cycle

Gas pre-flow time

End of welding

Gas post-flow time

Pull back torch trigger and hold it down

Release the torch trigger

Arc ignition

Welding with

pre-set main current I

H

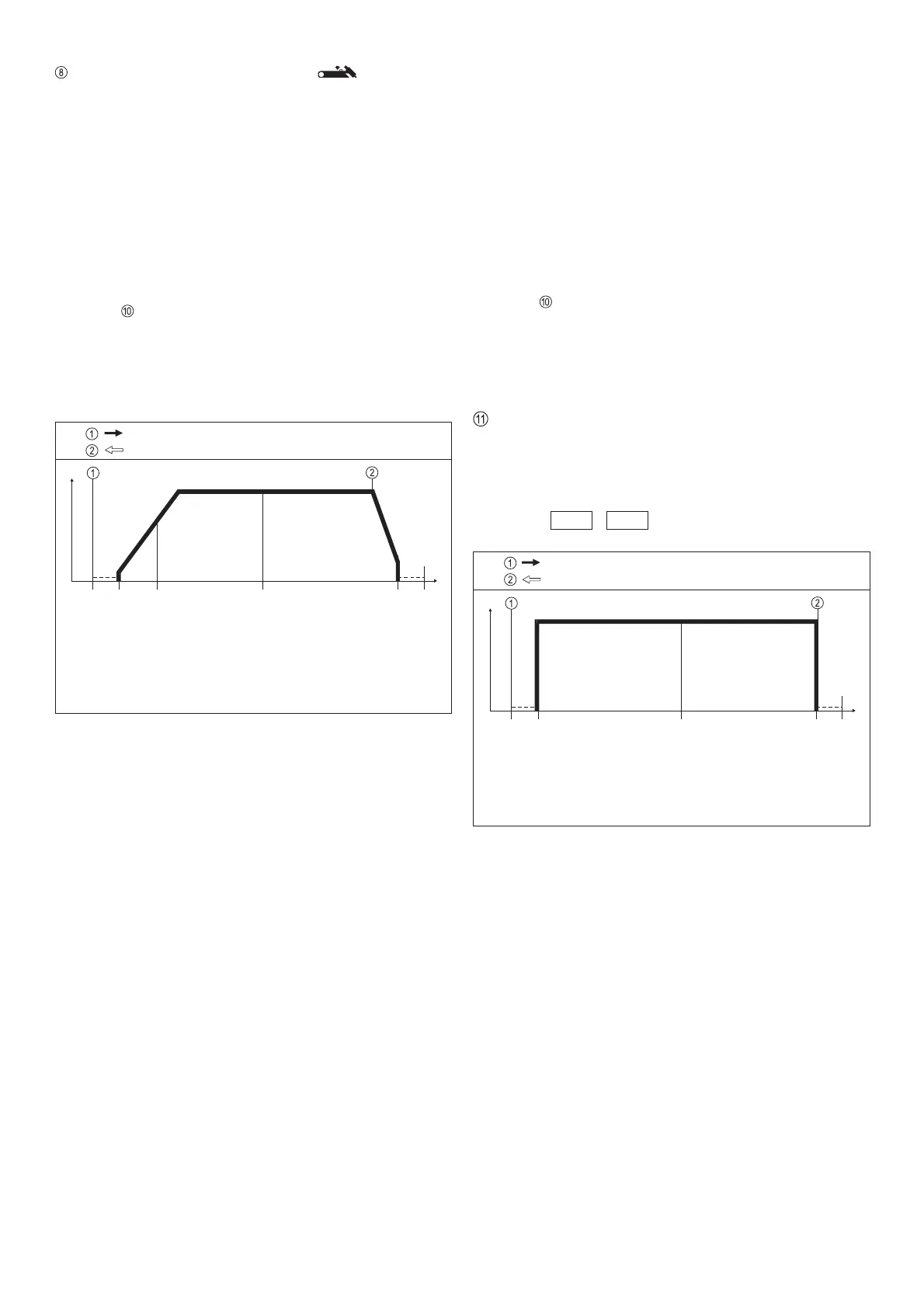

Fig. 6a Functional sequence in special 2-step mode

I

H

I

t

Start of cycle

Gas pre-flow time

Current rise via up-slope

End of welding with

Down-Slope off

crater-fill I

E

Gas post-flow time

Pull back torch trigger and hold it down

Release the torch trigger

Arc ignition with start arc I

S

Welding with pre-set

main current I

H

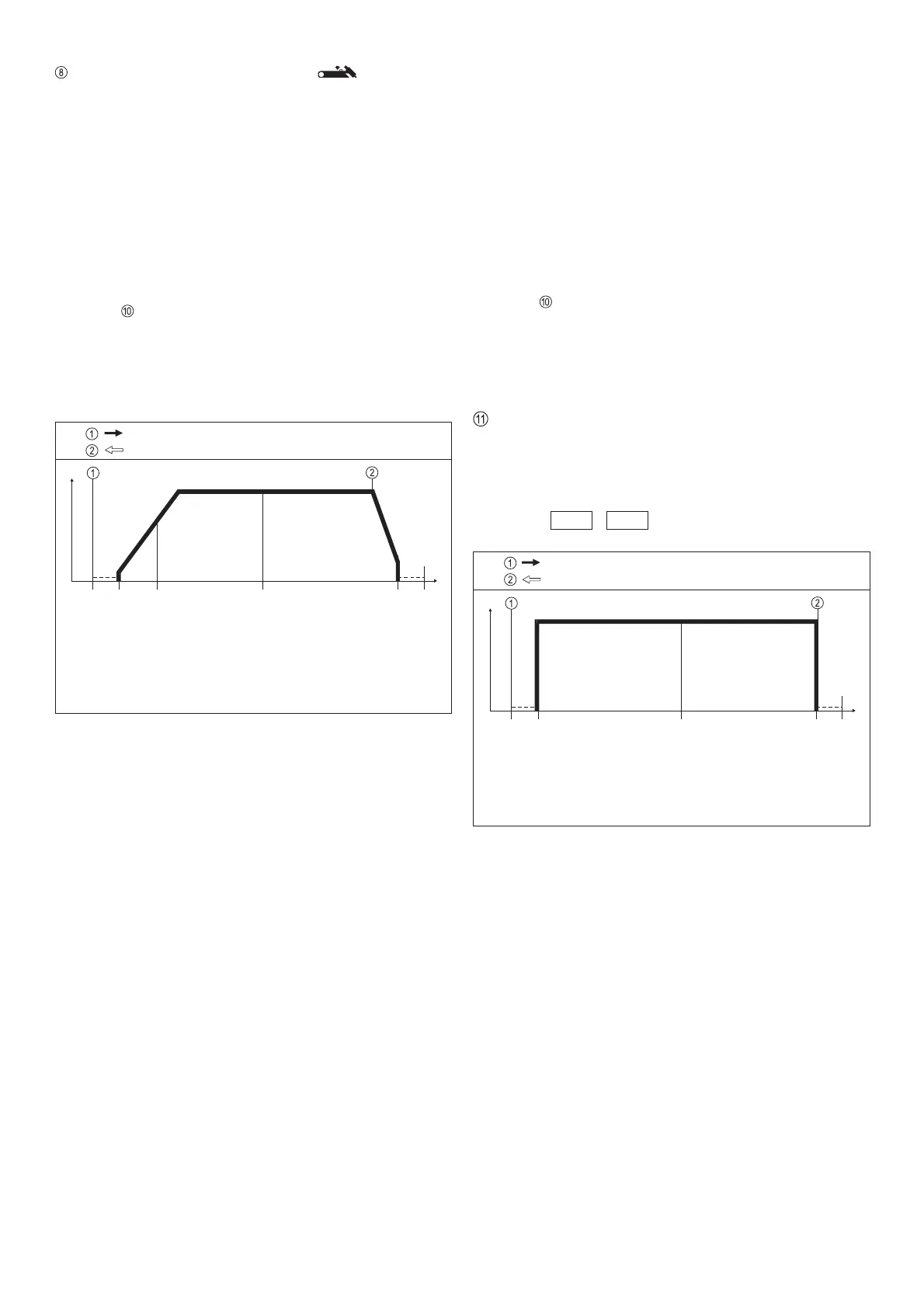

Fig. 6 Functional sequence in 2-step operating mode

I

H

I

t

LED INDICATOR FOR 2-STEP MODE

2-step mode (Fig.6)

l Activated from TIG torch trigger

l Mainly used for tack welding

l In the "PRESETTINGS LEVEL___" program level (TIG

parameters), StS must be set to OFF

Functional sequence:

1. Pull back and hold trigger

l Gas pre-flow time elapses

l Arc ignites at the pre-set start arc value I

S

(with HF ignition:

HF cuts out automatically after the ignition cycle)

l After ignition, the welding current rises via the internally pre-

set upslope to the welding current I

H

l LED lights up

2. Release trigger

l Arc goes out (with or without downslope)

l Internally pre-set gas post-flow time elapses

If a TR 52mc pedal remote-control unit is being used, the

machine automatically switches over to the 2-step mode.

Special 2-step mode (Abb.6a)

l Activated from TIG torch trigger

l Mainly used for tack welding

l In the "PRESETTINGS LEVEL___"

(see "Working with the program levels"), TIG parameters,

StS must be set to ON

Functional sequence:

1. Pull back and hold trigger

l Gas pre-flow time elapses

l Arc ignites at the pre-set start arc value I

S

(with HF ignition:

HF cuts out automatically after the ignition cycle)

l Welding current rises directly (without upslope) to welding

current I

H

l LED lights up

2. Release trigger

l Arc goes out (without downslope)

l Internally pre-set gas post-flow time elapses

If a TR 52mc pedal remote-control unit is being used, the

machine automatically switches over to the 2-step mode.

DOWN-SLOPE or current drop time

l For continuous adjustment of the current drop speed from

the main current down to the crater-fill current I

E

Range: 0,1 to 20 seconds

l When the Down-Slope potentiometer is used, the pre-set

value will be indicated for 3 seconds

e. g.: d S L 1.0

Loading...

Loading...