24

(27) Frequency range switch

Operating mode:

Regulation of pulse current I

1

using a remote control

- Link the connecting socket [G] on the power source and the remote-control unit

socket (28) electrically with the remote control cable.

- Plug in the plug-in connections the right way round, and screw the coupling ring on

as far as possible.

- LED indicator (13) blinks up on the power source

- Set desired operating mode with function button (4)

- The appropriate LED-indicator (5), (6), (7) or (8) lights up

- Pre-select the frequency range (0.2 - 2Hz, 2 - 20Hz, 20 - 200Hz, 200 - 2000Hz) with

the range switch (27).

- The pulsing current I

1

is set continuously with setting dial (23)

- The setting for the background current I

2

is made as a percentage of the pulsing

current I

1

, with setting dial (25)

- To select the duty cycle use dial (26)

- Set the pulse frequency dial (24) to the desired value.

- Mean welding-current amperage is indicated on display A

- The downslope parameter is set directly on the power source.

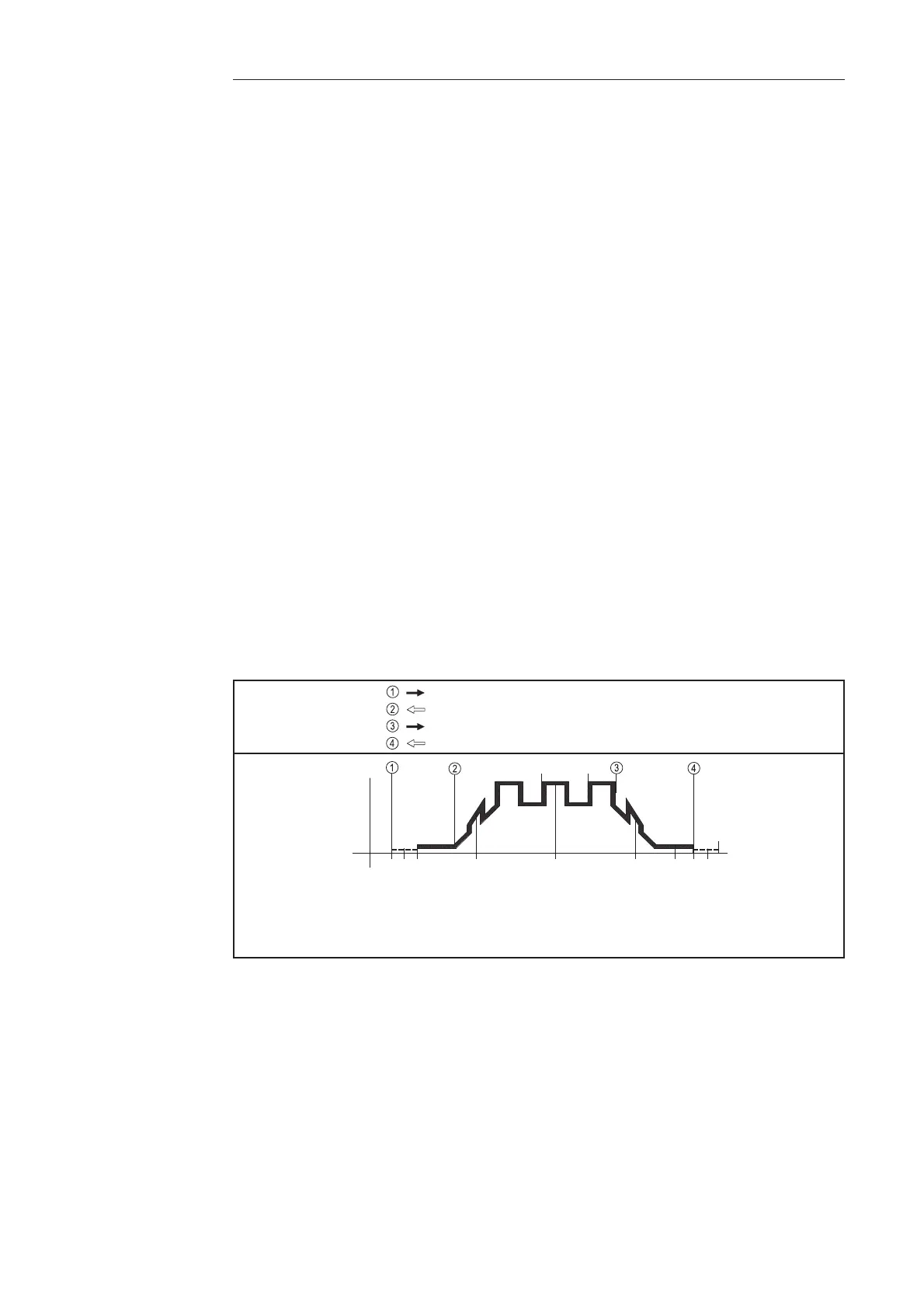

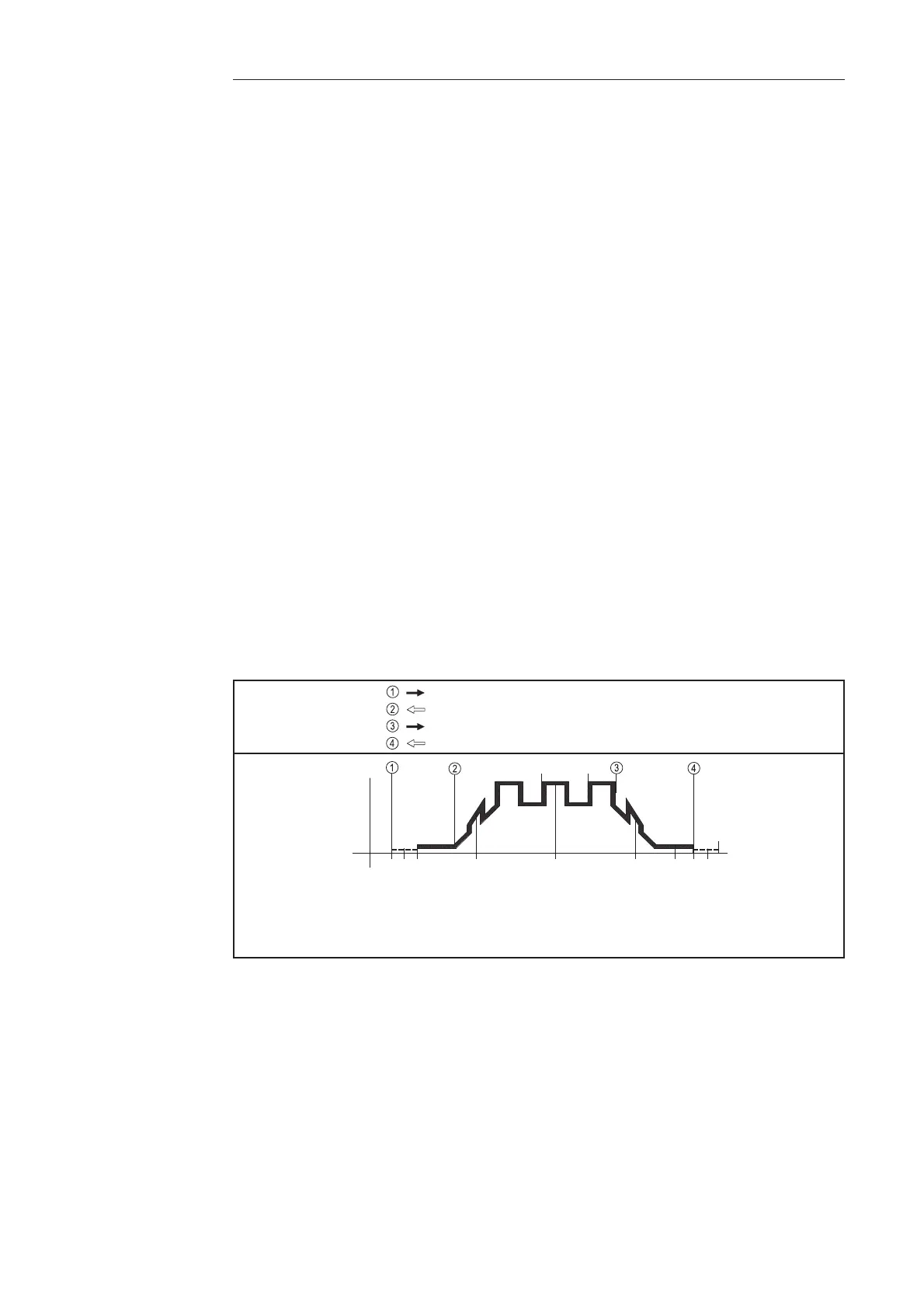

In the 4-step operating mode, the pulse phase begins as soon as the operator releases

the torch trigger in the up-slope. As can be seen in Fig. 12, pulsing also takes place in

the down-slope.

Important! If you wish to be able to switch from main current to crater-fill current while in

pulsed-arc mode (without interrupting welding), use:

- 4-step mode and a FRONIUS TIG torch with double control-switch function, or:

- special 4-step mode and a non-Fronius TIG torch

Please see chapter "Description of controls" for more details of the 4-step and special 4-

step operating modes.

TR 50mc remote

control pulsing

unit

(continued)

Gas pre-flow time

Fig. 24 Functional sequence in pulsed-arc welding operation using TR 50mc (4-step)

Release the torch trigger

Pull back and hold down the trigger once again

Release the torch trigger

Pull back torch trigger and hold down

I

1

I

2

f (Hz)

I

S

I

E

I

t

Start of cycle

Arc ignition

with start arc I

S

Pulsing current-rise

via up-slope

Pulsed-arc

welding operation

I

1

, I

2

/ f / Duty-Cycle

End of welding

Crater-fill current I

E

Gas post-flow time

Current-drop

(with pulse) via

down-slope

O

Loading...

Loading...