70

Procedure with TransTig power source for switching from MMA DC- welding to MMA

DC+ welding:

a) Move the mains switch to the O position

b) Disconnect the mains plug

c) Reconnect the electrode holder and the earthing (grounding) cable to the oppo-

site current sockets (i.e. swap them over)

d) Plug in the mains plug

e) Move the mains switch to the "I" position

all the indicators on the control panel will briefly light up

Select the desired welding current with the adjusting dial

The welding current value is displayed in the left-hand digital display.

Start welding

Hotstart function To obtain optimum welding results, it will sometimes be necessary to adjust the hotstart

function.

Benefits

- Improved ignition, even when using electrodes with poor ignition properties

- Better fusion of the base material in the start-up phase, meaning fewer cold-shut de-

fects

- Largely prevents slag inclusions

See the "Set-up menu: level 2" section for details on setting the available welding param-

eters.

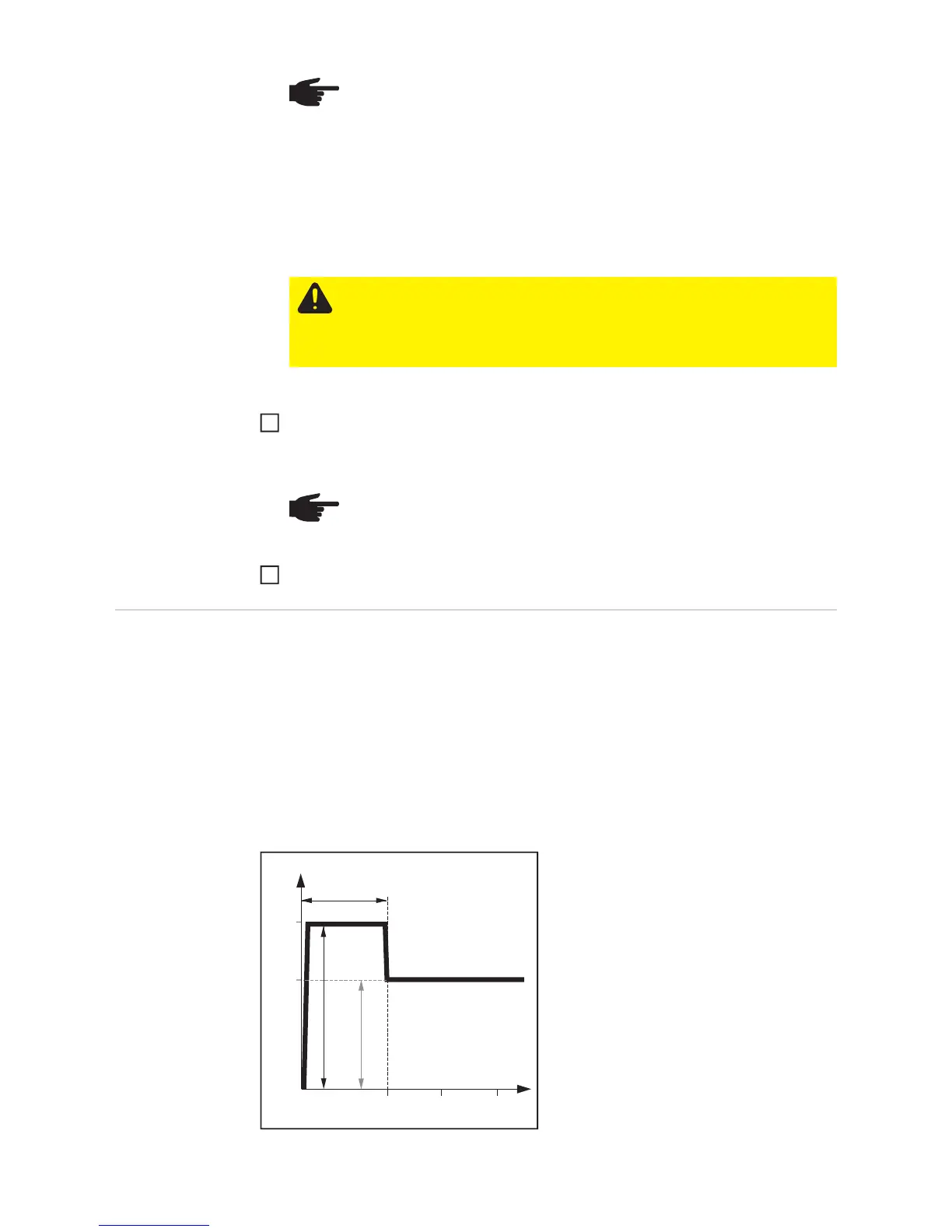

Example of hotstart function

Function:

during the specified hot-current time (Hti),

the welding current I

1

is increased to the

HotStart current HCU.

To activate the hotstart function, the Hot-

Start current HCU must be > 100.

NOTE! The TransTig power source has no switchover facility between the

MMA DC- and MMA DC+ welding processes.

CAUTION! Risk of injury and damage from electric shock. As soon as the

mains switch is in the "I" position, the rod electrode in the electrode holder is

live. Make sure that the rod electrode does not touch any persons or electri-

cally conducting or earthed parts (e.g. the housing etc.).

NOTE! All welding parameter set values that have been set using the adjust-

ing dial remain stored until the next time they are changed. This applies even

if the power source is switched off and on again in the meantime.

3

4

I (A)

t (s)

0,5 1 1,5

Hti

I

1

HCU

100

150

Legend

Hti Hot-current time, 0-2 s, factory

setting: 0.5 s

HCU HotStart current, 0-200%,

factory setting 150%

I

1

Main current = set welding current

Loading...

Loading...