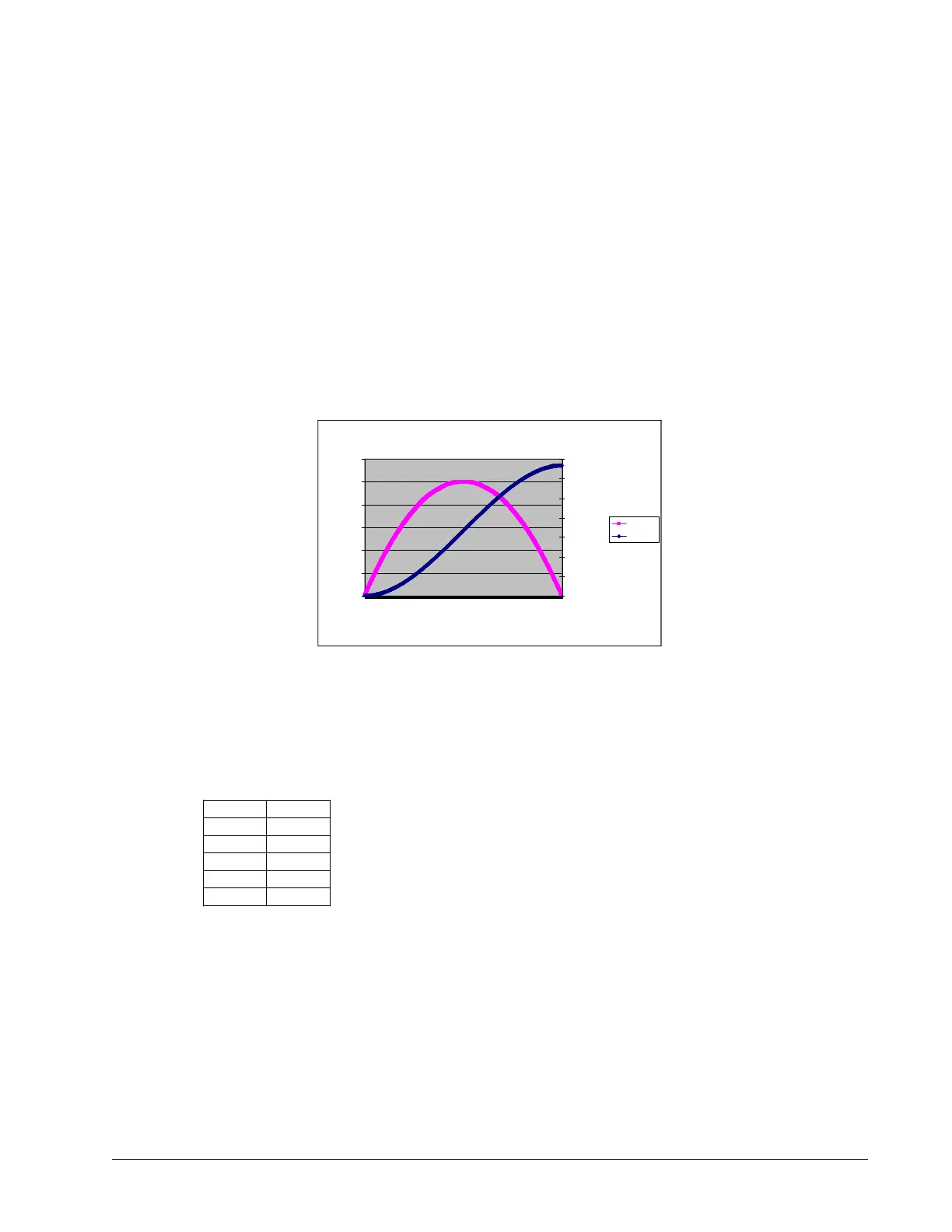

The DMC program is shown below and the results can be seen in Figure 6.16.

INSTRUCTION INTERPRETATION

#PVT

Label

PVX = 57,437,256

Incremental move of 57 counts in 256 samples with a final velocity of 437 counts/sec

PVX = 151,750,256

Incremental move of 151 counts in 256 samples with a final velocity of 750 counts/sec

PVX = 214,937,256

Incremental move of 214 counts in 256 samples with a final velocity of 937 counts/sec

PVX = 245,1000,256

Incremental move of 245 counts in 256 samples with a final velocity of 1000

counts/sec

PVX = 245,937,256

Incremental move of 245 counts in 256 samples with a final velocity of 937 counts/sec

PVX = 214,750,256

Incremental move of 214 counts in 256 samples with a final velocity of 750 counts/sec

PVX = 151,437,256

Incremental move of 151 counts in 256 samples with a final velocity of 437 counts/sec

PVX = 57,0,256

Incremental move of 57 counts in 256 samples with a final velocity of 0 counts/sec

PVX = 0,0,0

Termination of PVT buffer

BTX

Begin PVT

EN

Multi-Axis Coordinated Move

Many applications require moving two or more axes in a coordinated move yet still require smooth motion at the

same time. These applications are ideal candidates for PVT mode.

In this example we will have a 2 dimensional stage that needs to follow a specific profile. The application requires

that the certain points be met however the path between points is not important. Smooth motion between points

is critical.

The resultant DMC program is shown below. The position points are dictated by the application requirements and

the velocities and times were chosen to create smooth yet quick motion. For example, in the second segment the B

axis is slowed to 0 at the end of the move in anticipation of reversing direction during the next segment.

Chapter 6 Programming Motion ▫ 99 DMC-40x0 User Manual

Figure 6.16: Actual Velocity and Position vs Time of Parabolic Velocity Profile

Actual Velocity and Position vs Time

0

200

400

600

800

1000

1200

1400

Loading...

Loading...