GE Power Management 750/760 Feeder Management Relay 17-

17

17 COMMISSIONING 17.6 METERING

17

17.6.7 MEASUREMENT OF CURRENT DEMAND

Test Connections per Figure 17–1: RELAY TEST WIRING – WYE CONNECTION or Figure 17–2: RELAY

TEST WIRING – DELTA CONNECTION on page 17–4.

Expected Accuracy:

± 2.0% of full scale

To reset the "Last Demand" reading to 0 between tests, cycle the relay power source off/on.

Block Interval and Rolling demand measurement types must be tested in synchronization with the internal

clock. Both of these measurements start with the first interval of the day at 12:00:00.000 midnight. To synchro-

nize, preset the injection levels, then turn the current off. Select the relay display (not the 750/760PC program)

to

A1 STATUS \ CLOCK \ CURRENT TIME

. Apply the test current when the clock is at the beginning of an interval

measurement period, as determined by the

TIME INTERVAL

setpoint for the element.

Actual Values Displays:

Under subheading

A2 METERING \ DEMAND \ PHASE A CURRENT \

LAST PHASE A CURRENT DEMAND

MAX PHASE A CURRENT DEMAND

(DATE, TIME)

Under subheading

A2 METERING \ DEMAND \ PHASE B CURRENT \

LAST PHASE B CURRENT DEMAND

MAX PHASE B CURRENT DEMAND (DATE, TIME)

Under subheading

A2 METERING \ DEMAND \ PHASE C CURRENT \

LAST PHASE C CURRENT DEMAND

MAX PHASE C CURRENT DEMAND (DATE, TIME)

Procedure:

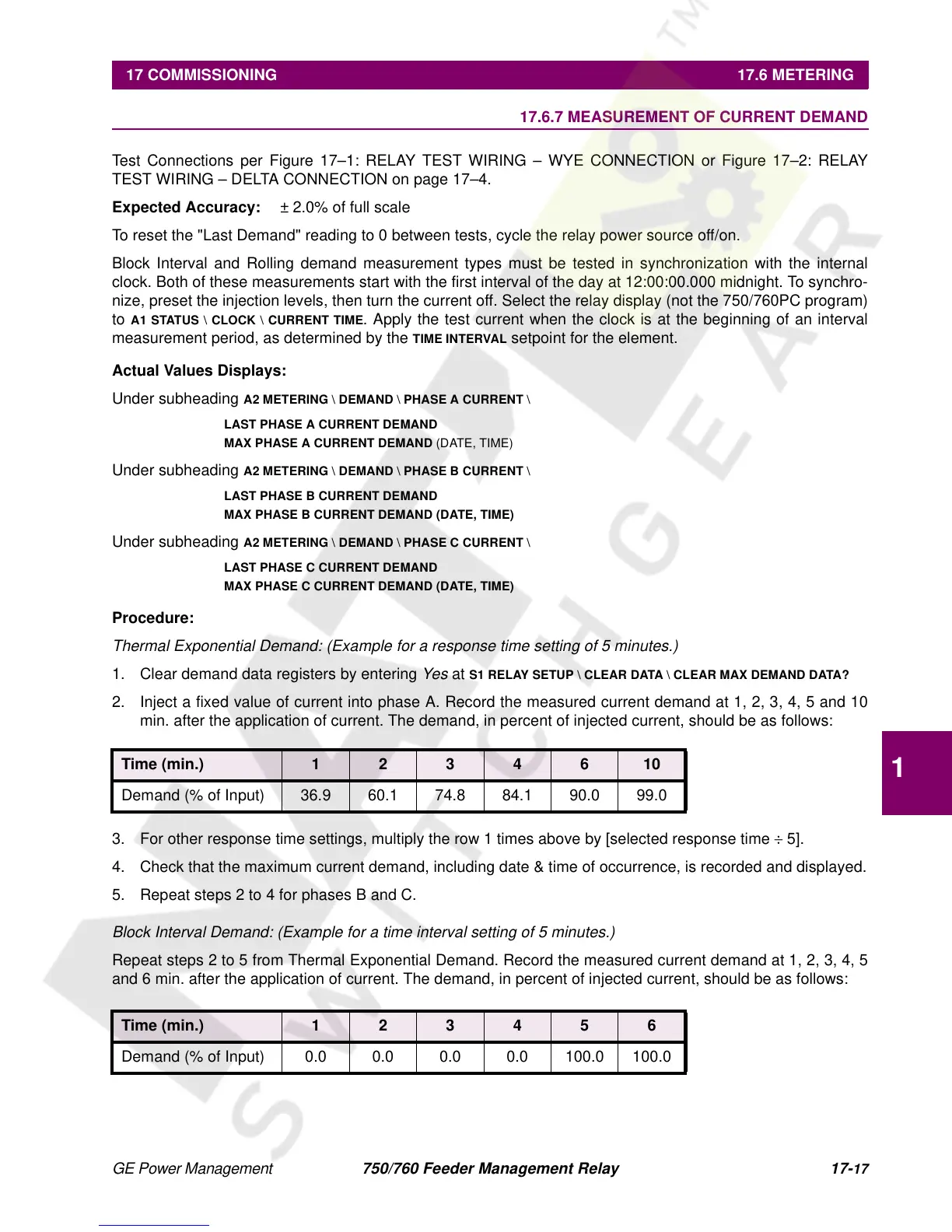

Thermal Exponential Demand: (Example for a response time setting of 5 minutes.)

1. Clear demand data registers by entering

Yes

at

S1 RELAY SETUP \ CLEAR DATA \ CLEAR MAX DEMAND DATA?

2. Inject a fixed value of current into phase A. Record the measured current demand at 1, 2, 3, 4, 5 and 10

min. after the application of current. The demand, in percent of injected current, should be as follows:

3. For other response time settings, multiply the row 1 times above by [selected response time

÷

5].

4. Check that the maximum current demand, including date & time of occurrence, is recorded and displayed.

5. Repeat steps 2 to 4 for phases B and C.

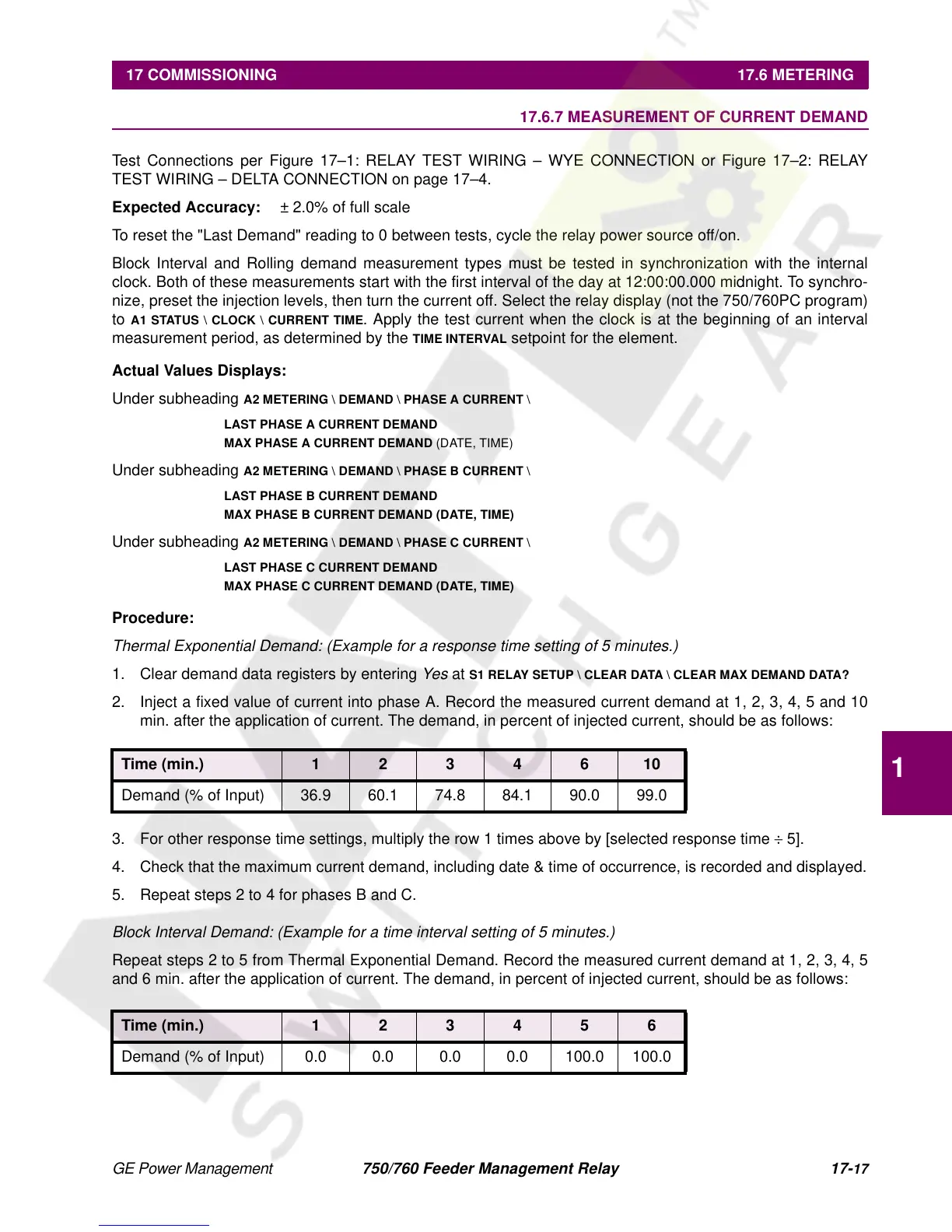

Block Interval Demand: (Example for a time interval setting of 5 minutes.)

Repeat steps 2 to 5 from Thermal Exponential Demand. Record the measured current demand at 1, 2, 3, 4, 5

and 6 min. after the application of current. The demand, in percent of injected current, should be as follows:

Time (min.) 1 2 3 4 6 10

Demand (% of Input) 36.9 60.1 74.8 84.1 90.0 99.0

Time (min.) 1 2 3 4 5 6

Demand (% of Input) 0.0 0.0 0.0 0.0 100.0 100.0

Loading...

Loading...