17-

18

750/760 Feeder Management Relay GE Power Management

17.6 METERING 17 COMMISSIONING

17

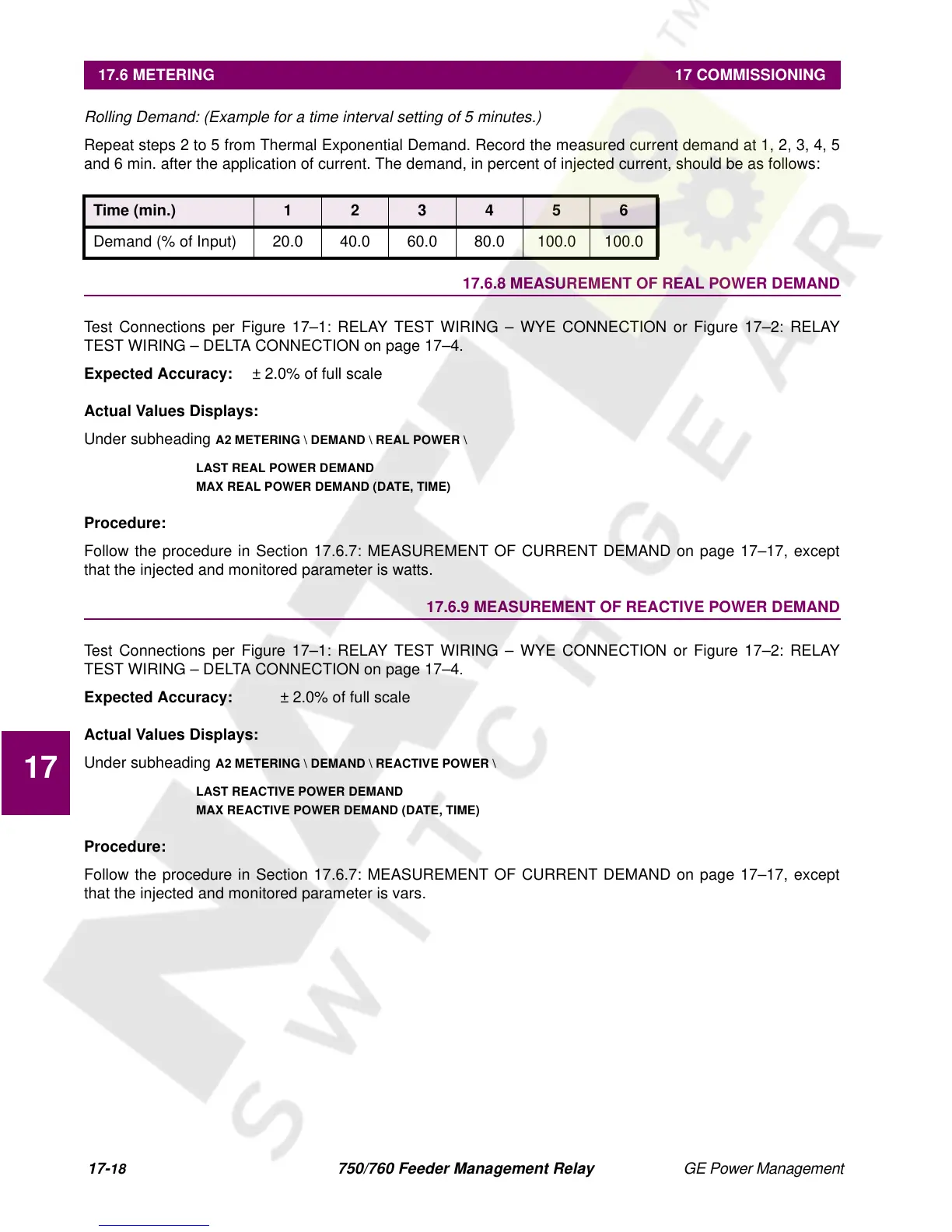

Rolling Demand: (Example for a time interval setting of 5 minutes.)

Repeat steps 2 to 5 from Thermal Exponential Demand. Record the measured current demand at 1, 2, 3, 4, 5

and 6 min. after the application of current. The demand, in percent of injected current, should be as follows:

17.6.8 MEASUREMENT OF REAL POWER DEMAND

Test Connections per Figure 17–1: RELAY TEST WIRING – WYE CONNECTION or Figure 17–2: RELAY

TEST WIRING – DELTA CONNECTION on page 17–4.

Expected Accuracy:

± 2.0% of full scale

Actual Values Displays:

Under subheading

A2 METERING \ DEMAND \ REAL POWER \

LAST REAL POWER DEMAND

MAX REAL POWER DEMAND (DATE, TIME)

Procedure:

Follow the procedure in Section 17.6.7: MEASUREMENT OF CURRENT DEMAND on page 17–17, except

that the injected and monitored parameter is watts.

17.6.9 MEASUREMENT OF REACTIVE POWER DEMAND

Test Connections per Figure 17–1: RELAY TEST WIRING – WYE CONNECTION or Figure 17–2: RELAY

TEST WIRING – DELTA CONNECTION on page 17–4.

Expected Accuracy:

± 2.0% of full scale

Actual Values Displays:

Under subheading

A2 METERING \ DEMAND \ REACTIVE POWER \

LAST REACTIVE POWER DEMAND

MAX REACTIVE POWER DEMAND (DATE, TIME)

Procedure:

Follow the procedure in Section 17.6.7: MEASUREMENT OF CURRENT DEMAND on page 17–17, except

that the injected and monitored parameter is vars.

Time (min.) 1 2 3 4 5 6

Demand (% of Input) 20.0 40.0 60.0 80.0 100.0 100.0

Loading...

Loading...