Do you have a question about the GE Discovery NM/CT 670 and is the answer not in the manual?

Provides essential safety information for operating the system and ensuring user well-being.

Details the hazard classifications (DANGER, WARNING, CAUTION) used throughout the manual.

Explains formatting, symbols, and special notations used in the manual for clarity.

Outlines the manual's purpose and the information provided for site preparation professionals.

Details the customer's duties in site preparation, including adherence to specifications and drawings.

Specifies guidelines for system component handling, transportation, and unpacking.

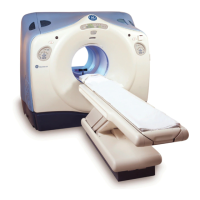

Describes the NM/CT hybrid system and illustrates its various components with figures.

Provides guidelines for scan and operator room dimensions, layout, and component placement.

Details requirements for floor, ceiling, and wall construction, including acoustic and vibration specs.

Covers radiation shielding regulations and requirements for staff and background radiation reduction.

Addresses electrostatic discharge, electromagnetic interference, and immunity for optimal performance.

Emphasizes maintaining constant temperature and humidity for system functionality and component longevity.

Provides a table detailing the heat output (BTU/hr and Watt) of system components.

Recommends dedicated feeder runs and details transformer size and feeder requirements.

Specifies requirements for line voltage, frequency, and measured kVa load characteristics.

Details the system's equal potential grounding system and its primary grounding points.

Confirms that relevant site personnel have read the safety and system overview manuals.

Confirms that pre-installation is complete and all checklist items have been verified.

Lists the necessary tools for accurately measuring floor flatness according to specifications.

Outlines minimum clearances required by U.S. federal regulations and national standards.

Specifies minimum working clearances for subsystems like gantry, table, console, and PDU.

Defines service clearances needed to safely perform maintenance and remove system covers.

| Manufacturer | GE Healthcare |

|---|---|

| Model | Discovery NM/CT 670 |

| Imaging Modalities | SPECT, CT |

| Image Reconstruction | Iterative Reconstruction |

| Gantry Aperture | 70 cm |

| CT Tube Voltage | 80, 100, 120, 140 kV |

| SPECT Detectors | 2 |

| CT Detector Rows | 16 |

| Patient Weight Capacity | 204 kg (450 lbs) |

| Detector Type | Solid-state digital detectors |

| CT Slice Thickness | 0.625 mm to 10 mm |

| Patient Positioning | Supine |

| Software | Xeleris |

| CT Tube Current | 10 mA to 500 mA |

| Energy Range | 70 keV to 511 keV |

| Collimators | LEHR, MEGP |