Do you have a question about the GE Diamond and is the answer not in the manual?

Guidelines and precautions for safe use of X-ray radiation.

Ensuring safe siting and operation of the unit to prevent injury.

Explanation of the sophisticated mammography Automatic Exposure Control (AEC) system.

How to view and set the compression force limits for examinations.

Functionality for motor-driven backward movement of the tube head for access.

Details on the motorized C-Arm rotation and safety considerations.

Control buttons for adjusting the vertical position of the C-Arm.

How to select projection angles (CC, OBL, LAT) using control buttons.

Procedures for compressing the breast using paddles and foot pedals.

Description of the acrylic compression plate and metal supporting frame.

Explanation of the foot switches used for compression control.

Manual and motorized methods for applying and adjusting breast compression.

Easy Compression System for independent C-Arm movement and improved image quality.

Guidance on patient positioning for mammographic examinations.

Step-by-step guide for performing CC projections.

Procedure for positioning and imaging oblique views.

Steps for performing medio-lateral projections.

Steps involved in making an X-ray exposure.

Recommended technique factors for various breast thicknesses and situations.

How to initiate and complete an X-ray exposure.

Procedures for performing manual biopsies, including paddle attachment.

Using the stereotactic feature for high-quality biopsies.

Using the system to automatically determine kV for exposures.

Using selectable detectors for automatic exposure control.

Performing quality control tests to ensure consistent image density.

Step-by-step guide for conducting the IQC test with a phantom.

Troubleshooting steps for when the unit shows no power.

Diagnosing issues when the ready light is not active.

How to resolve a compression paddle stuck issue.

Understanding and responding to error codes displayed on the LCD.

Reference table for error codes, reasons, and corrective actions.

Procedures for cleaning and disinfecting the unit and its parts.

Procedures for checking unit performance and contacting distributors.

Maximum rated peak tube potential and continuous tube current.

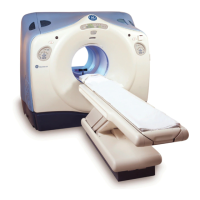

| Model | Diamond |

|---|---|

| Type | Digital Mammography System |

| X-ray Tube Voltage | 20-35 kV |

| Manufacturer | GE |

| Technology | Digital |

| Detector Type | Amorphous Selenium (a-Se) |

| Compression Force | 30-200 N |

| X-ray Tube | Molybdenum target |

| X-ray Tube Current | 100 mA |

| Focal Spot Size | 0.1/0.3 mm |

| Filter Options | Molybdenum, Rhodium |

| Workstation Compatibility | GE workstation |

| Power Requirements | 220-240 V, 50/60 Hz |

| Regulatory Approvals | FDA, CE |