3-20 F650 Digital Bay Controller GEK-106310AE

3.1 ENERVISTA 650 SETUP SOFTWARE INTERFACE 3 HUMAN INTERFACES. SETTINGS & ACTUAL VALUES

3

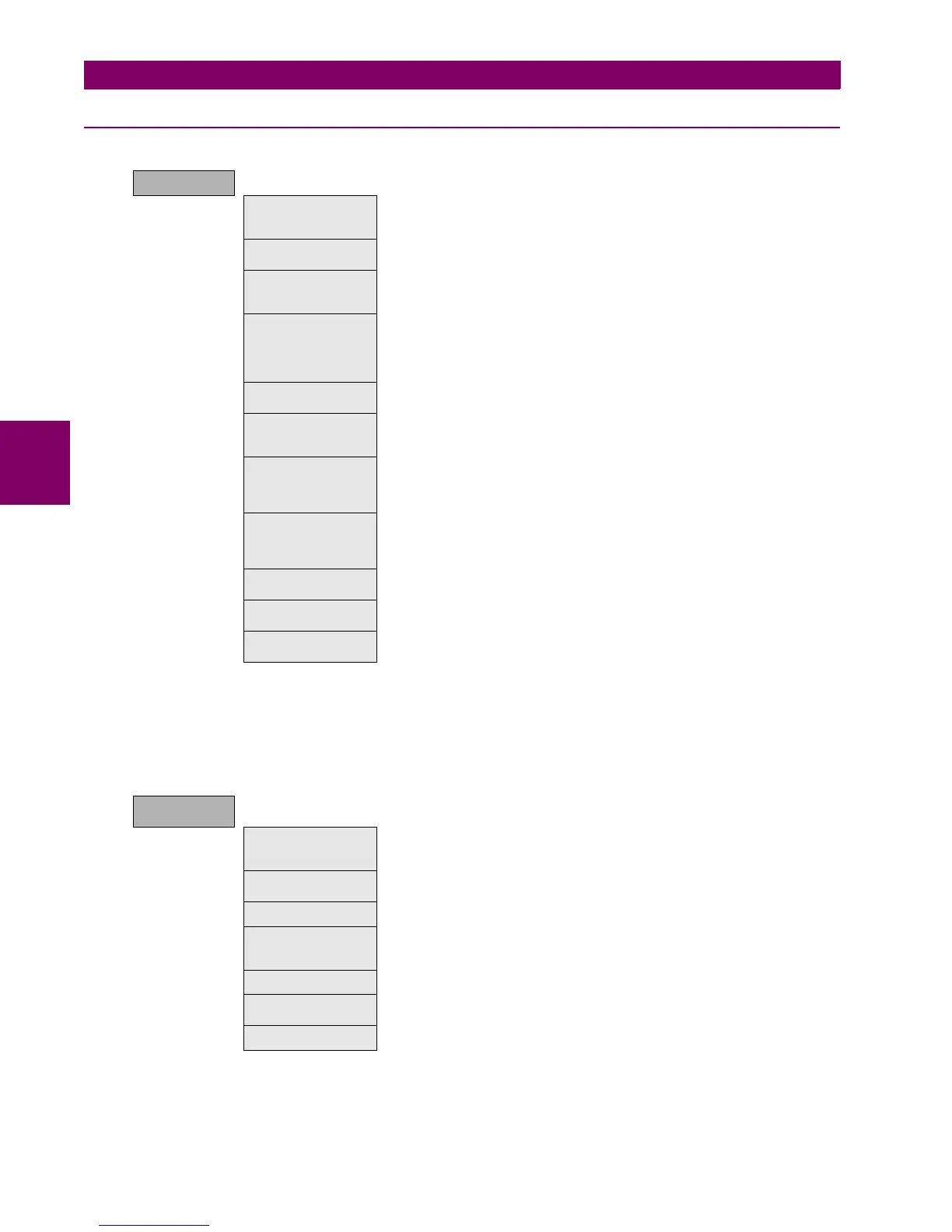

3.1.8 SETPOINT MENU OVERVIEW

Table 3.5: GENERAL OVERVIEW OF SETPOINT MENU IN ENERVISTA 650 SETUP:

Options enabled only in On-line mode are marked as (*). Options enabled only in Off-line mode are marked as (**)

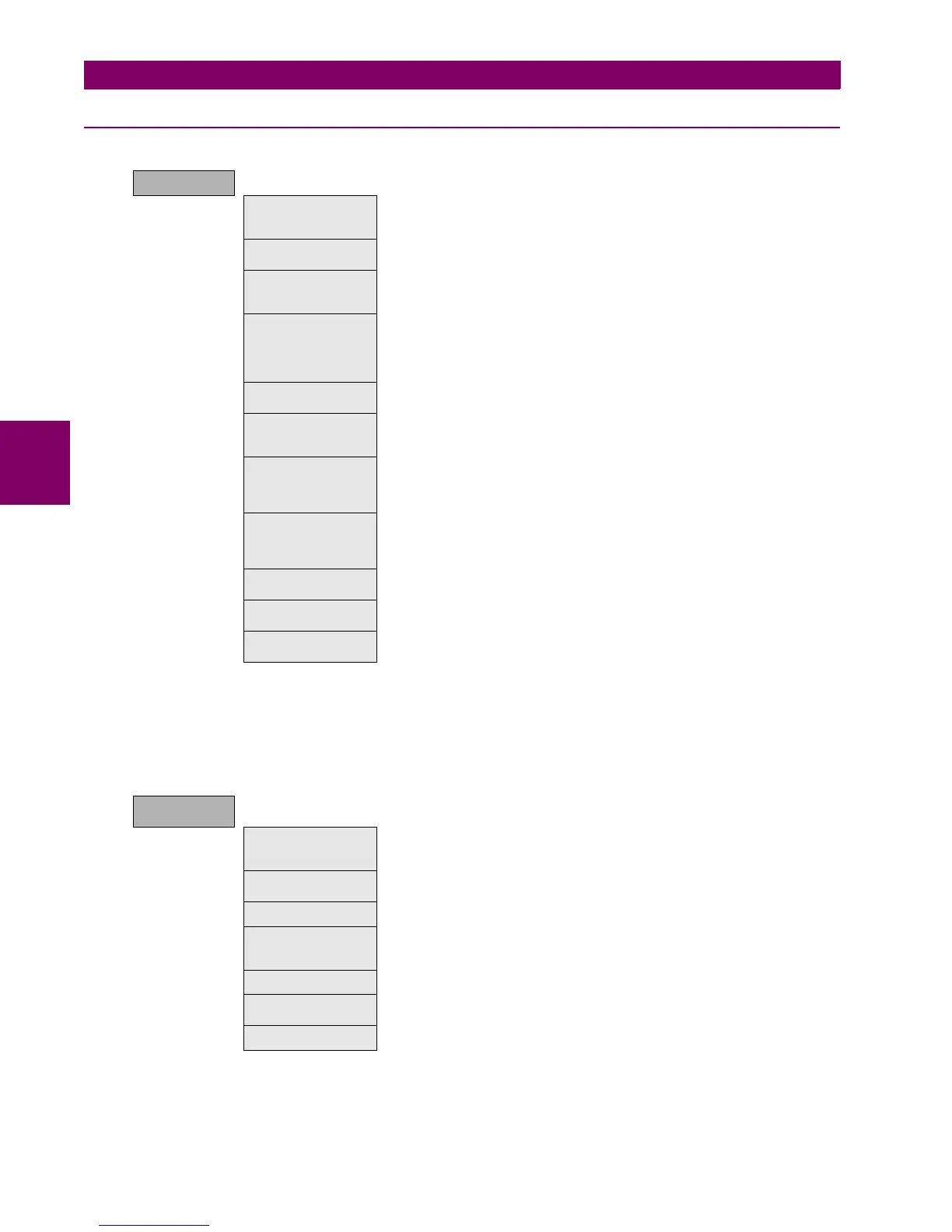

3.1.8.1 PRODUCT SETUP

Table 3.6: GENERAL OVERVIEW OF PRODUCT SETUP MENU:

Options enabled only in On-line mode are marked as (*). Options enabled only in Off-line mode are marked as (**)

SETPOINT

Product Setup

Communications settings for all protocols and physical mediums.

ModBus user map definition, fault report, oscillography, data logger

demand settings and Time Settings.

System Setup

General Settings, Flex Curves Definition, Breaker settings maintenance,

switchgear snapshot events management and Miscellaneous Settings.

Protection Elements

Phase, Neutral, Ground, Sensitive Ground and Negative Sequence

Current Settings. Voltage Elements settings and Power Settings

management.

Control Elements

Setting groups, under and overfrequency settings, synchrocheck,

autoreclose, breaker failure, VT fuse failure, broken conductor, locked

rotor settings management, Pulse Counters, Analog comparators,

Frequency Rate of Change, Load encroachment, max number of starts,

Digital Counters, Cold Load Pickup and PLC Timer Masks

Inputs/Outputs

Contact I/O settings for all boards available in device, Remote Comms

Force Outputs and Virtual inputs.

Quick Settings

Menu that encompass the most important settings to configure the

device such as; Current and Voltage sensing or current protection

element.

Relay Configuration

Configuration of Outputs, LEDs, Operations, Protection Elements,

Oscillography, Control Events, Control Elements, Switchgear, Inputs,

Virtual Inputs, Operations and HMI. Whole relay configuration with

internal relay signals or user-definable ones as logic (virtual outputs).

Logic Configuration

Logic configuration graphic editor (PLC Editor). It is a PLC Project file

editor that contains all the internal drawings used to make the logic

(virtual outputs) based on IEC 61131-3 standard. Functional block

diagram (FDB).

Procome Configuration

Procome Configuration tool. Only available for Procome models (5)

when communicating through Ethernet with EnerVista 650 Setup

IEC103 Configuration

IEC103 settings for available IEC103 models (3) when communicating

through Ethernet with Enervista 650 Setup

Clock (*)

Relay synchronization to computer clock or to user-definable date and

time. On-line mode only.

PRODUCT

SETUP

Communication

Settings

Serial Ports, Network (Ethernet), ModBus Protocol, DNP Slave, IEC 870-

5-104, SNTP settings and procome (if available on model selection),

PTP1588 and Routing (for firmware version 7.00 and higher)

ModBus User Map

ModBus user map definition. The ModBus user map is formed by 256

records, selectable from the complete relay ModBus map.

Fault Report Fault report settings. Possibility to show fault reports on HMI screen.

Oscillography

Oscillography settings (trigger position, samples per cycle, etc.). The

trigger and digital channels (up to 16) must be configured in

"Setpoint>Relay configuration".

Data Logger Data logger configuration

Demand

Demand settings. The demand trigger and demand reset signals must be

configured in "Setpoint>Relay configuration"

Time Settings Time settings.

Loading...

Loading...