36

11. Remove the steam nozzle.

12. Remove the four 1/4 in. hex screws that hold the

rear drum support to the side panels.

13. Lift the front drum support out of the key holes.

Drum Roller

Th e d r yer u ses f o ur r o ll er s t o sup p or t t h e d r um . The

rollers can be replaced by removing the triangular

FODPSDQGSXOOLQJUROOHUVRȺ

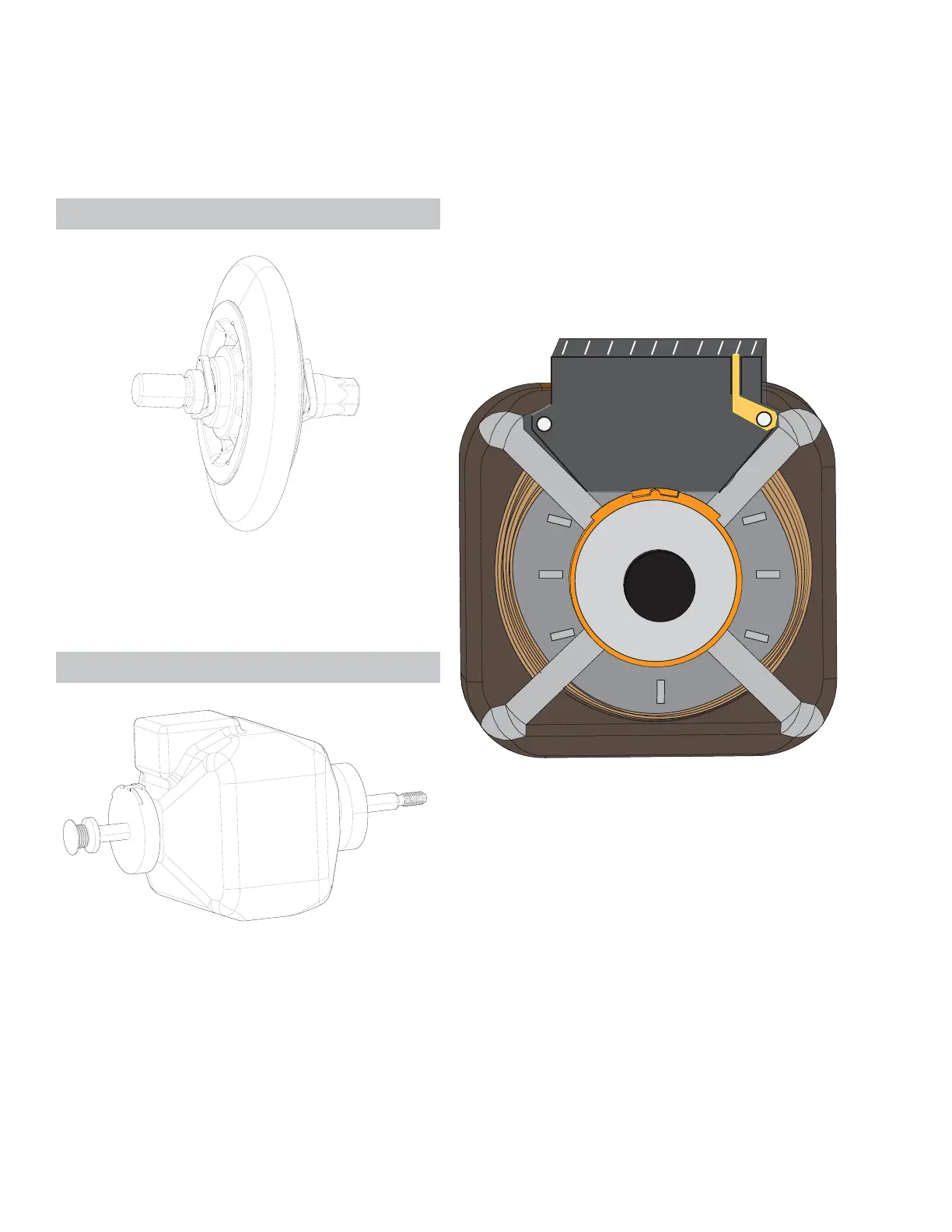

Mot or

7KHPRWRULVORFDWHGRQWKHGU\HUÀRRURQWKHOHIW

side.

Oper at i ng Volt age: 120 VAC Reversible

Horsepower: 1/ 3

R,P.M.: 1725

Main Winding Resistanceű

St a r t W i n d i n g Re s i s t a n c e ű

Th e m ot o r i s u sed t o dr i ve t h e d r u m an d bl ow er

wheel. Motor reversal is accomplished by the drum

reversing relay located on the main control board.

Th e r el ay sw a ps t h e l o ca t i on of l in e a nd n eu t r a l.

Th e m ot o r h as t w o cen t r i f u ga l sw i t c hes t h a t a re l a-

beled A and B on the schematic. Switch A controls L2

to the heater, and switch B connects L1 to either the

start winding when the motor is not running or t o the

main control board when the motor is running.

Mot or Connect or

2 6 8 4 3 9 7 5 1

GND

Pi n 1: Cent rifugal Swit ch A input

Pi n 2: Cent rifugal Swit ch A output

Pi n 3: Cent rifugal Swit ch B N.C.

Pi n 4: Main winding neutral

Pi n 5: Main winding L1

Pi n 6: Cent rifugal Swit ch B N.O.

Pi n 7: St art Winding (Aux 2)

Pi n 8: St art winding (Aux 1)

Pi n 9: Motor TCO out put

Mot or Removal

1. Disconnect power from the unit .

2. Remove the control panel.

3. Remove the front panel.

4. Remove the trap duct .

See Re a r D u c t Rem o v a l o n p a g e 3 9 .

See N o zzl e H o l d e r Rem o v a l o n p a g e 4 9 .

See M o t o r Lo c a t i o n o n p a g e 19 .

See M o t o r D i r e c t i o n 1 H i g h l i g h t o n p a g e 5 1.

See M o t o r D i r e c t i o n 2 Hi g h l i g h t o n p a g e 5 2.

See Co n t r o l Pa n e l Rem o v a l o n p a g e 2 0 .

See Fr o n t Pa n e l Re m o v a l o n p a g e 2 4 .

Loading...

Loading...