5-164 M60 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

SYSTEM SETUP CHAPTER 5: SETTINGS

5

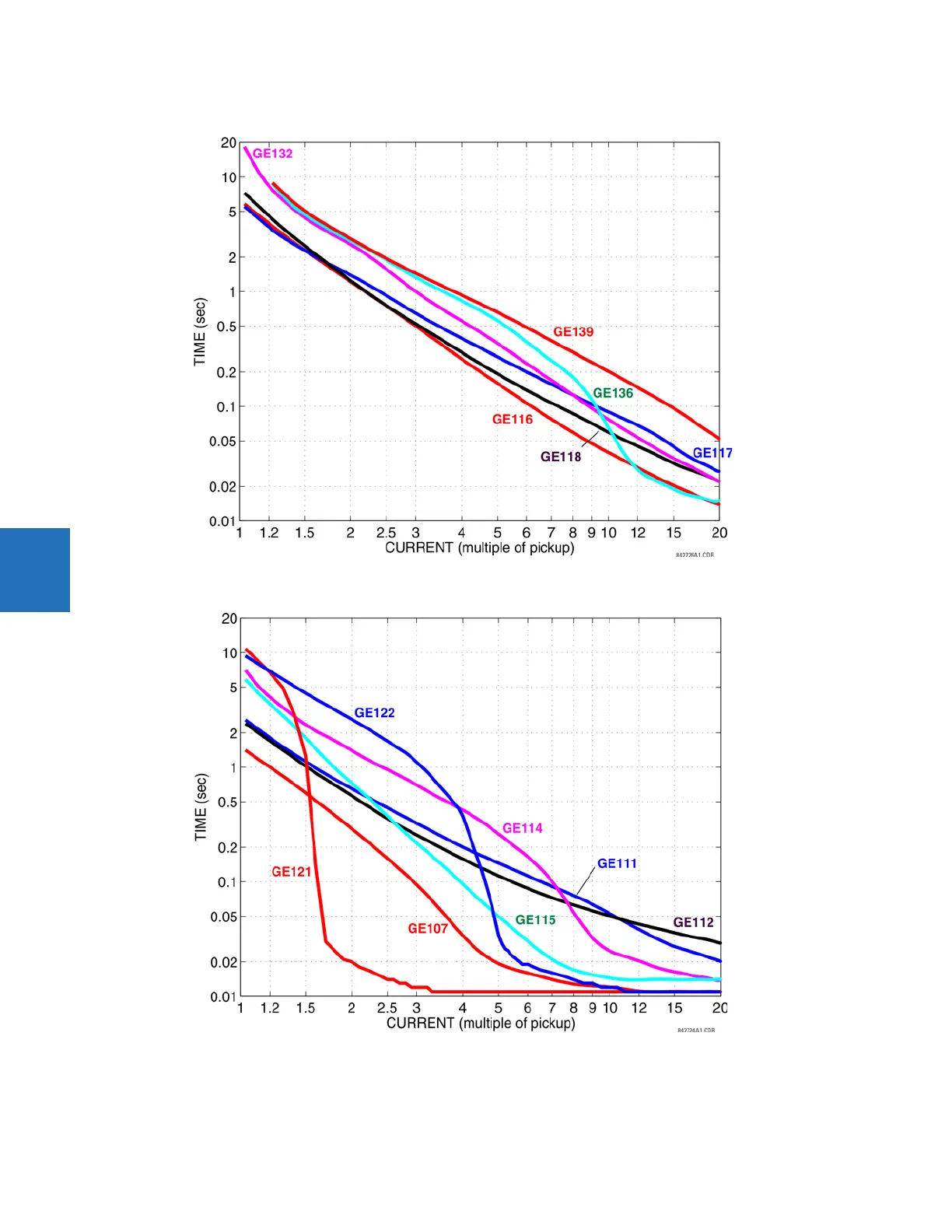

Figure 5-83: Recloser curves GE116, GE117, GE118, GE132, GE136, and GE139

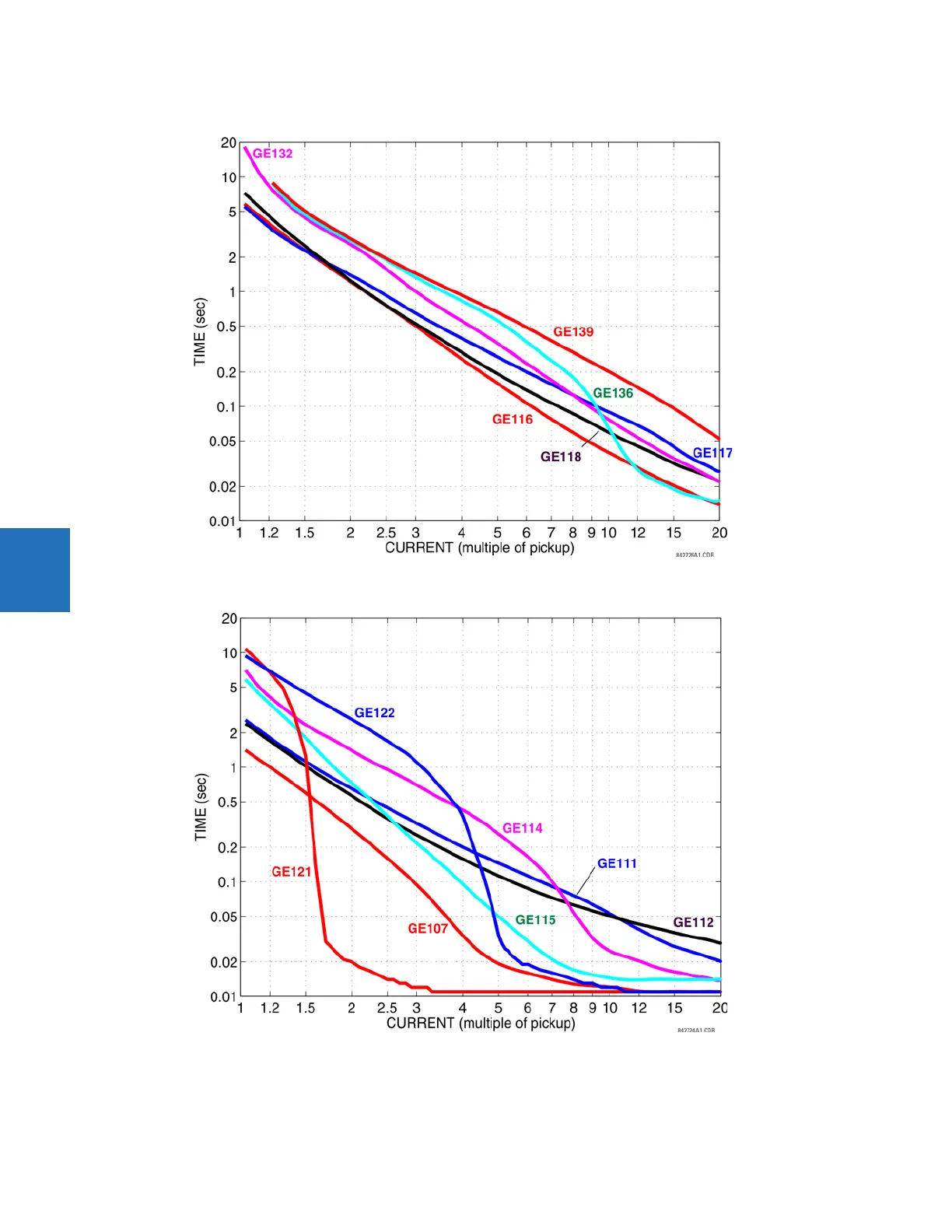

Figure 5-84: Recloser curves GE107, GE111, GE112, GE114, GE115, GE121, and GE122

Loading...

Loading...