PanaFlow™ XMT1000 User’s Manual 5

Chapter 1. Installation

1.4.4 Local Mounting

The XMT1000 accuracy is affected by the flowcell location in the process piping and on the orientation of the

transducers. Thus, in addition to accessibility for maintenance, adhere to the following installation guidelines:

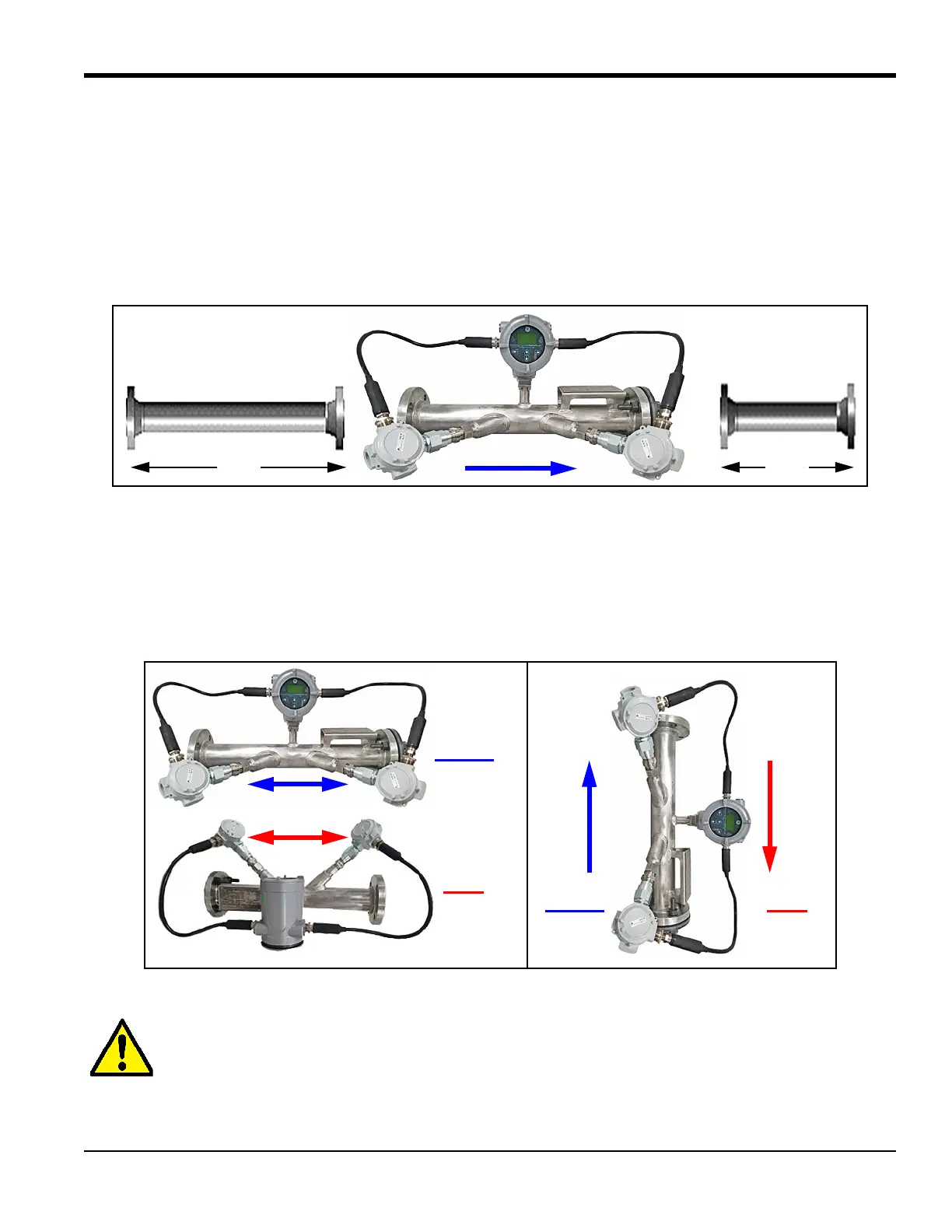

• Locate the flowcell so that there are at least 10 pipe diameters of straight, undisturbed flow upstream and

5 pipe diameters of straight, undisturbed flow downstream from the measurement point (see Figure 4 below).

Undisturbed flow means avoiding sources of turbulence in the fluid (e.g., valves, flanges, expansions, elbows,

etc.), avoiding swirl, and avoiding cavitation.

Figure 4: Minimum Straight Run Pipe Requirements

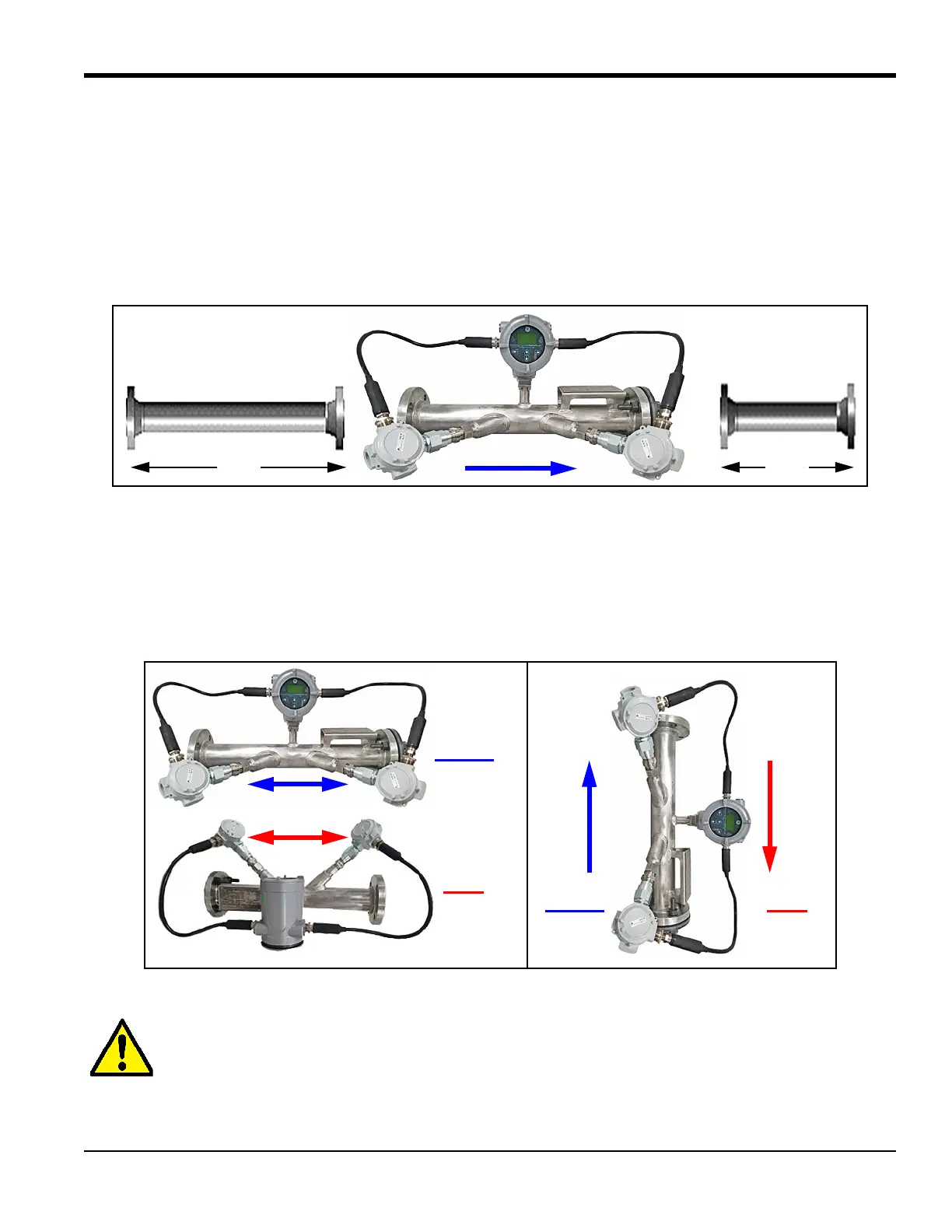

• Locate the transducers on a common axial plane along the pipe. Also, locate them on the side of the pipe

instead of on the top or the bottom, because the top of the pipe tends to accumulate gas and the bottom tends to

accumulate sediment. Either condition will cause unwanted attenuation of the ultrasonic signals. There is no

similar restriction with vertical pipes, as long as the fluid flow is upward to prevent free falling of the fluid or a

less than full pipe (see Figure 5 below).

Figure 5: Good and Bad Flowcell/Transducer Orientations

CAUTION! Do not place thermal insulation on or around the transducers, the junction boxes, or the

meter electronics. The transducer and junction box act as a heat sink that protects the transducer

from high and low temperatures.

BAD

Vertical

GOOD

Flow Direction

Flow Direction

Flowcell

Flow Direction

GOOD

BAD

Horizontal

Flowcell

Loading...

Loading...