Chapter 3. Error Codes and Troubleshooting

26 PanaFlow™ XMT1000 User’s Manual

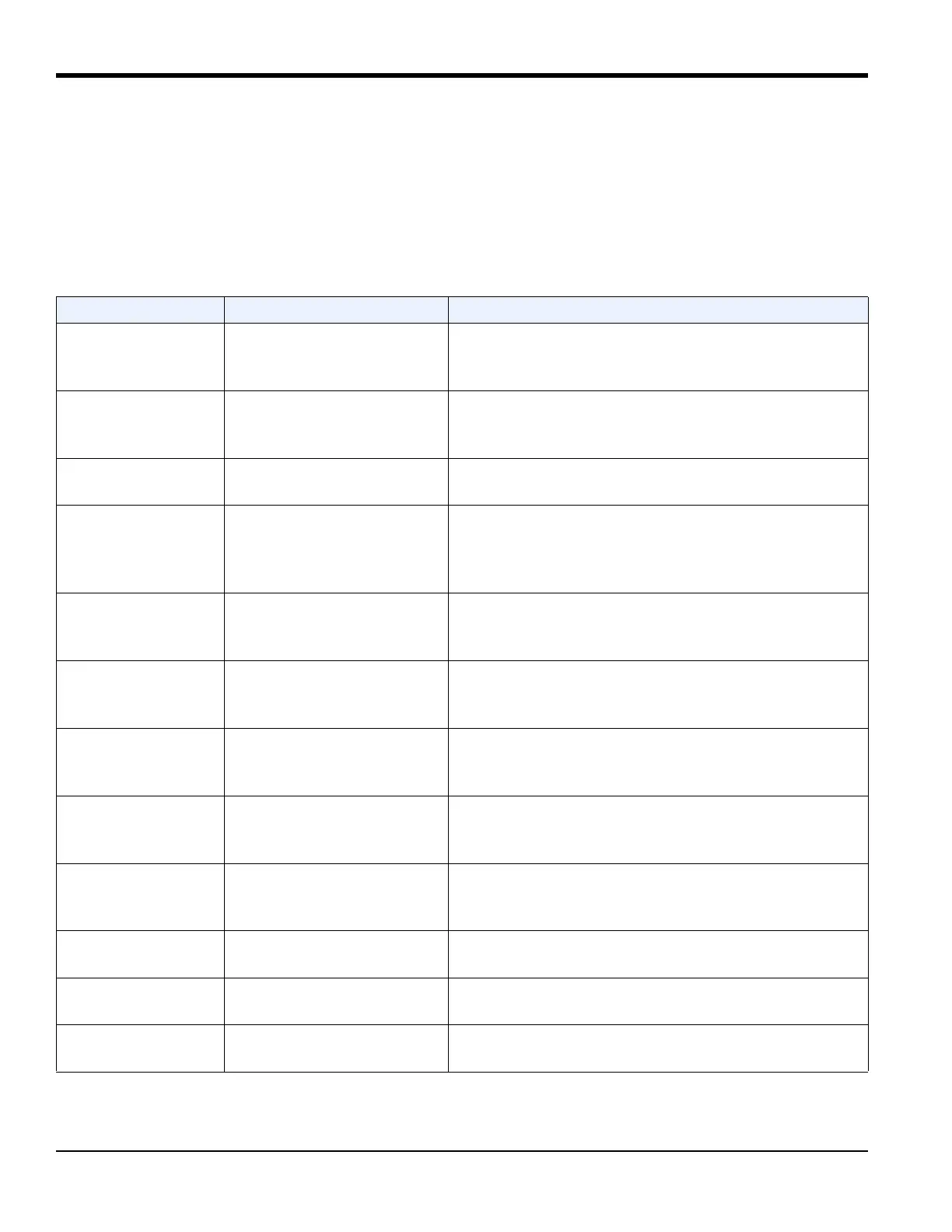

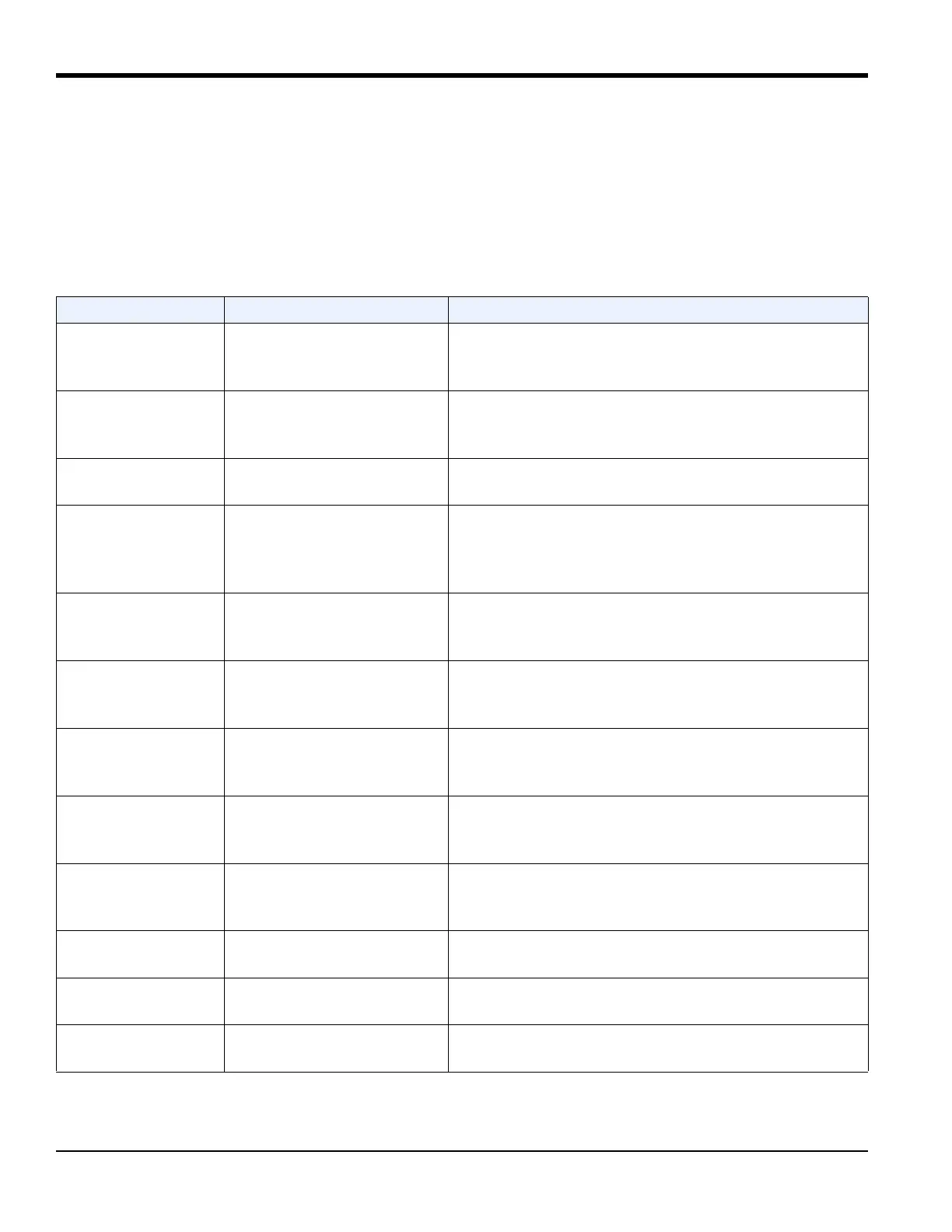

3.1.3 Flow Error String

Flow errors are errors detected by the Flow PCB in the course of making a flow measurement. These errors can be

caused by disturbances in the fluid, such as excessive particles in the flow stream or extreme temperature gradients.

The errors could also be caused by an empty pipe or other such issue with the fluid itself. Flow errors are typically not

caused by a malfunction of the flow measurement device, but by an issue with the fluid itself.

Note: For troubleshooting tips, see “Diagnostics” on page 27.

Table 4: Flow Error String

Error Code Error Message Description

E1: SNR The Signal to Noise ratio is

low.

The acoustic signal from the process is very low. This could

be due to bubbles, other fluid conditions, an empty pipe,

broken cables, transducers, couplant or buffers.

E2: Soundspeed The measured soundspeed

exceeds programmed limits.

The error may be caused by incorrect programming, poor

flow conditions or poor transducer orientation. It may also

occur if signal quality is poor.

E3: Velocity Range The measured velocity exceeds

programmed limits.

This error may be caused by incorrect programming, poor

flow conditions and/or excessive turbulence.

E4: Signal Quality The signal quality is lower than

the programmed limits.

This means the signal shape, upstream to downstream

reciprocity, or signal correlation value has fallen below the

correlation peak limit. The cause is usually the same as E6 or

E5.

E5: Amplitude The signal amplitude exceeds

the programmed limits.

This error may occur due to high signal attenuation or

amplification due to changes in fluid properties, or

transducer/buffer/couplant issues.

E6: Cycle Skip A cycle skip is detected while

processing the signal for

measurement.

This is usually due to poor signal integrity, possibly because

of bubbles in the pipeline, sound absorption by very viscous

fluids, or cavitation.

E15: Active Tw The Active Tw measurement is

invalid.

A transducer or cable is damaged, or a transducer needs to

be re-coupled. This may also be due to incorrect

programming, or extreme process temperatures.

E22: Single Channel

Accuracy

One of the measurement

channels is in error.

One measurement channel is in error; accuracy of the

measurement may be compromised because the meter might

be using a sister chord substitution.

E23: Multi Channel

Accuracy

Two or more measurement

channels are in error.

Two or more measurement channels are in error; accuracy of

the measurement may be compromised because the meter is

using a sister chord substitution.

E28: Software Fault There is a software malfunction This is a software malfunction. Try power cycling the meter.

If the error persists after power cycle, contact GE factory.

E29: Velocity Warning The measured velocity exceeds

programmed warning limits.

This error may be caused by incorrect programming, poor

flow conditions and/or excessive turbulence.

E31: Not Calibrated The flow meter has not been

calibrated.

The flow meter has not been calibrated and hence is not

making measurements.

Loading...

Loading...