Electric Auxiliary Controls

Adjustment (Fig. 7-3)

If your loader is hand & foot operated, it may be

equipped with electrically controlled auxiliary

hydraulics. Follow the procedure below for adjustment

of those controls.

1. With the panel switch down, adjust potentiometer

#2 clockwise until a squealing or ticking in the

actuator is heard or felt. Turn counterclockwise

slightly to obtain full retraction without squealing or

ticking. Continue turning counterclockwise another

1/8 of a turn.

2. With the panel switch down and the handle switch to

the left, adjust potentiometer #4 counterclockwise

until a squealing or ticking is heard or felt. Turn

clockwise slightly to obtain full extension without

squealing or ticking. Continue turning clockwise

another 1/8 of a turn.

3. With the panel switch up, adjust potentiometer #1

counterclockwise until a squealing or ticking is

heard or felt. Turn clockwise slightly to obtain full

extension without squealing or ticking. Continue

turning clockwise another 1/8 of a turn.

4. With the handle switch to the left, adjust

potentiometer #3 clockwise until a squealing or

ticking is heard or felt. Turn counterclockwise

slightly to obtain full retraction without squealing or

ticking. Continue turning counterclockwise another

1/8 of a turn.

907808/CP0300 50 PRINTED IN USA

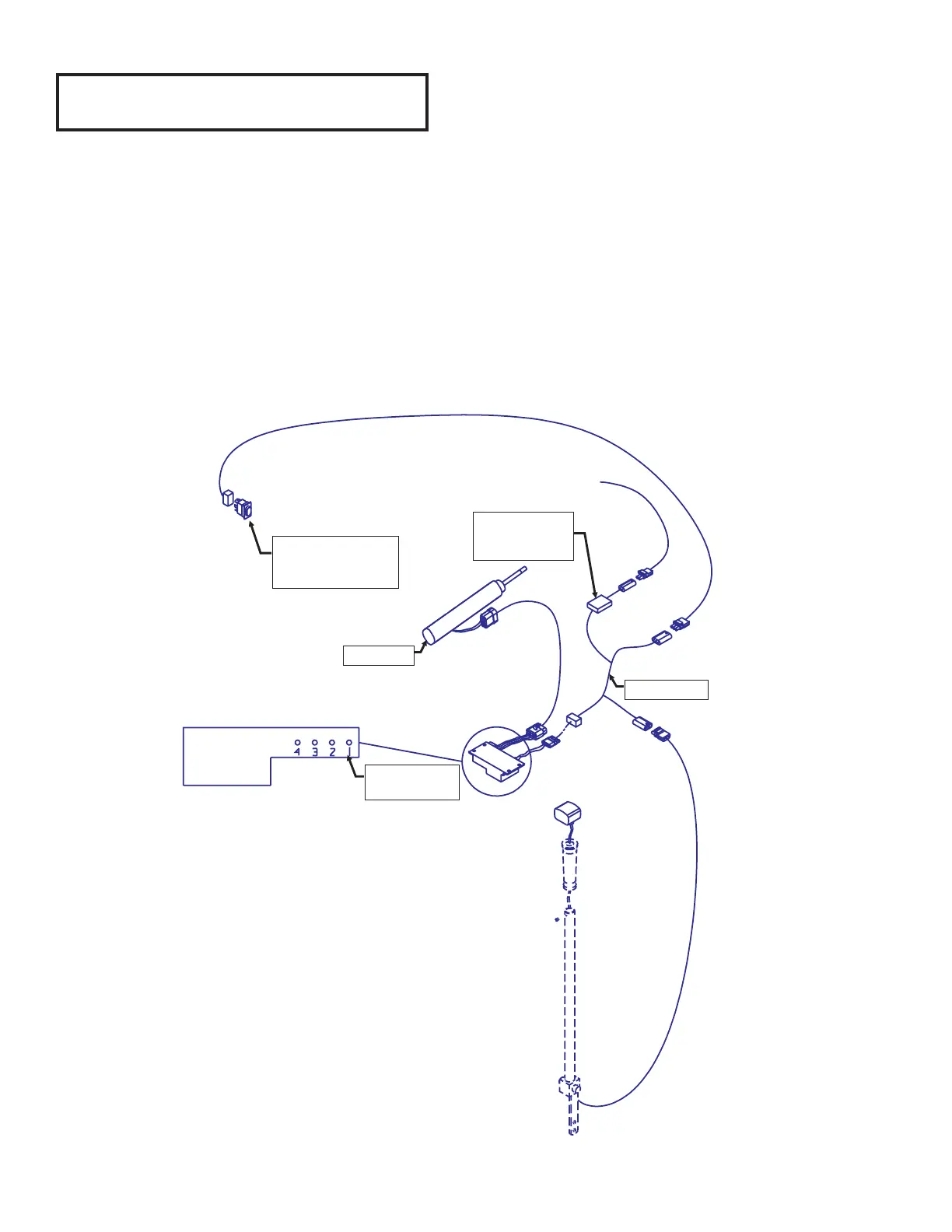

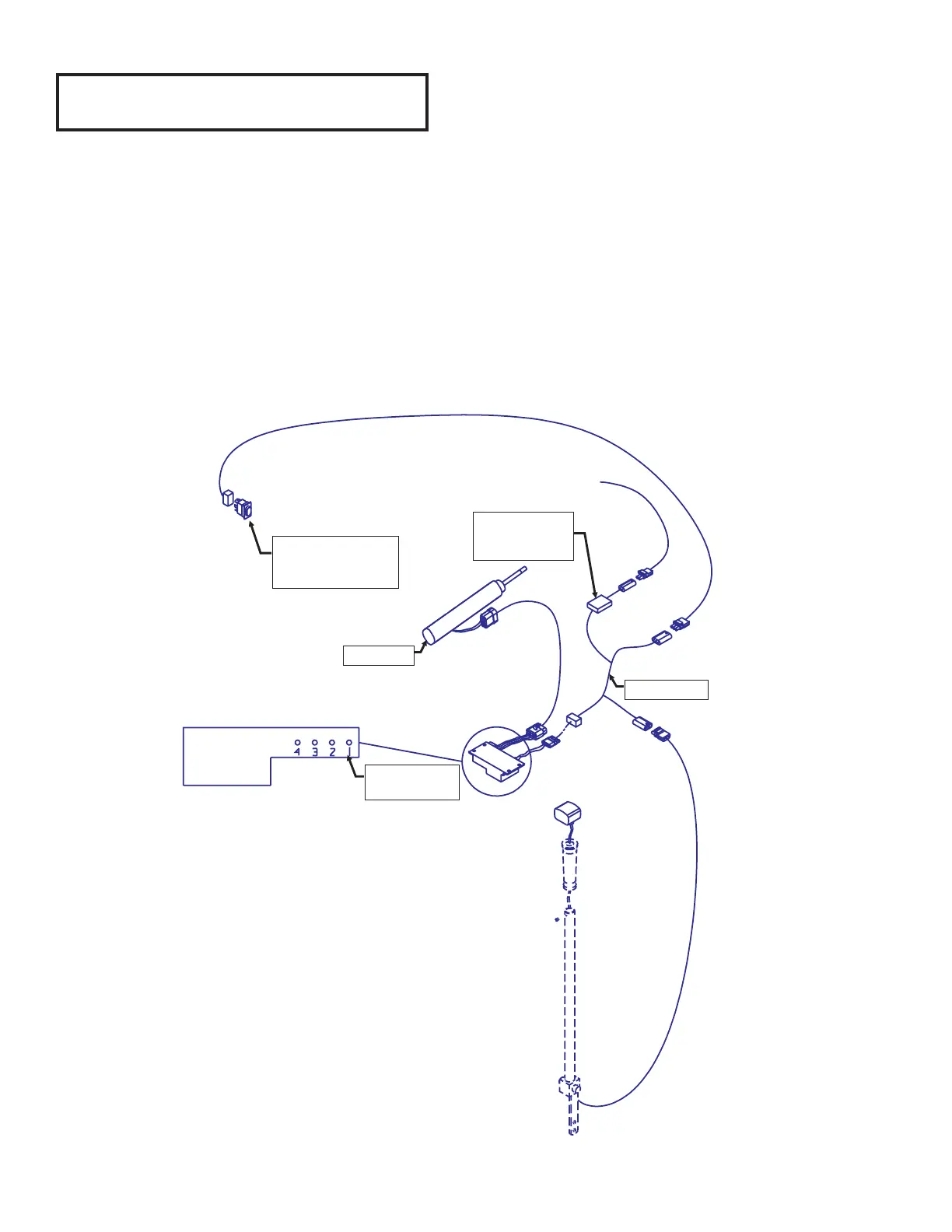

Fig. 7-3: Electric Auxiliary Controls Adjustment

Rocker switch

located on

instrument panel

Actuator

Fuseholder with

5 amp AGC

Blade-type fuse

Gehl harness

Potentiometer

numbers

Controller

From engine harness power -

left front of engine

Clockwise = Retract

Loading...

Loading...