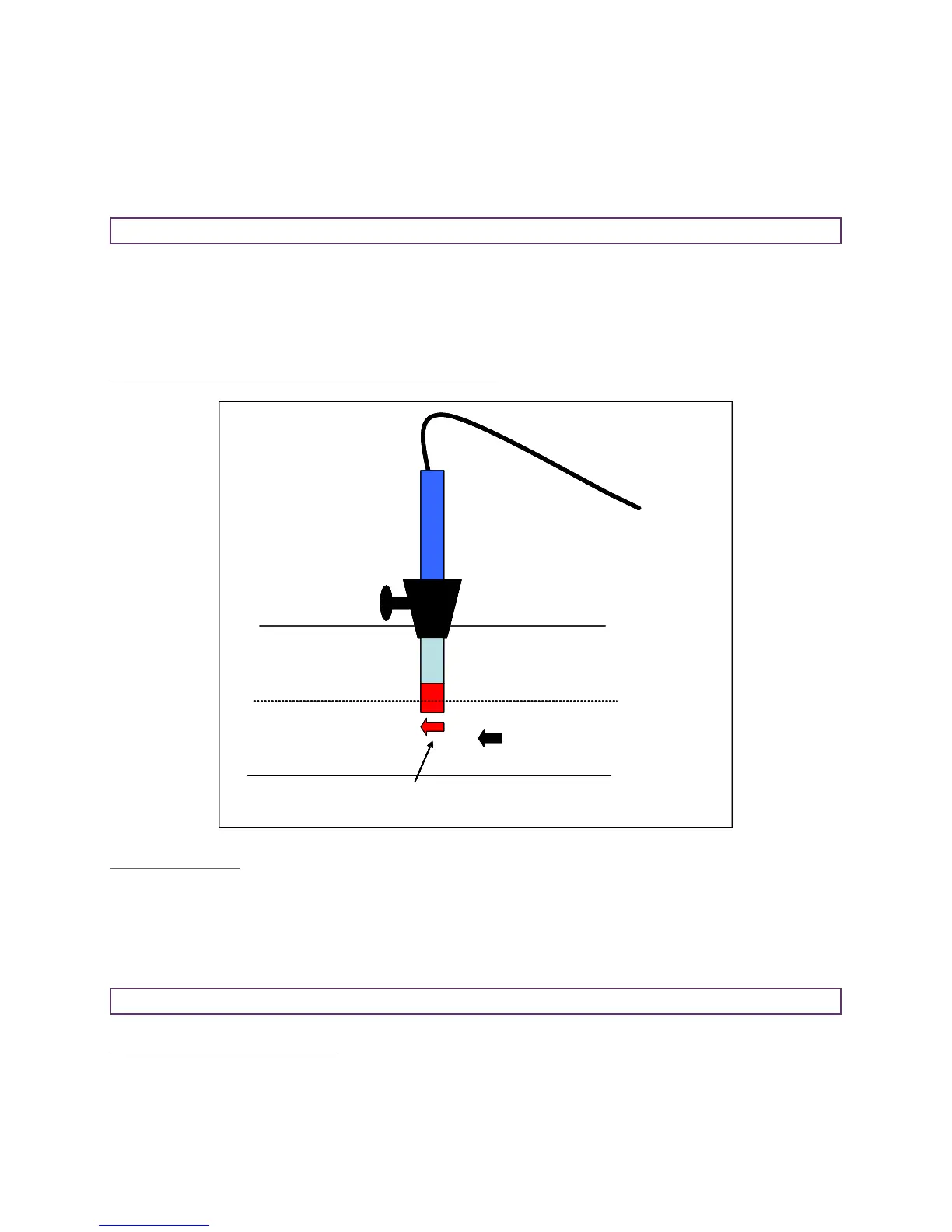

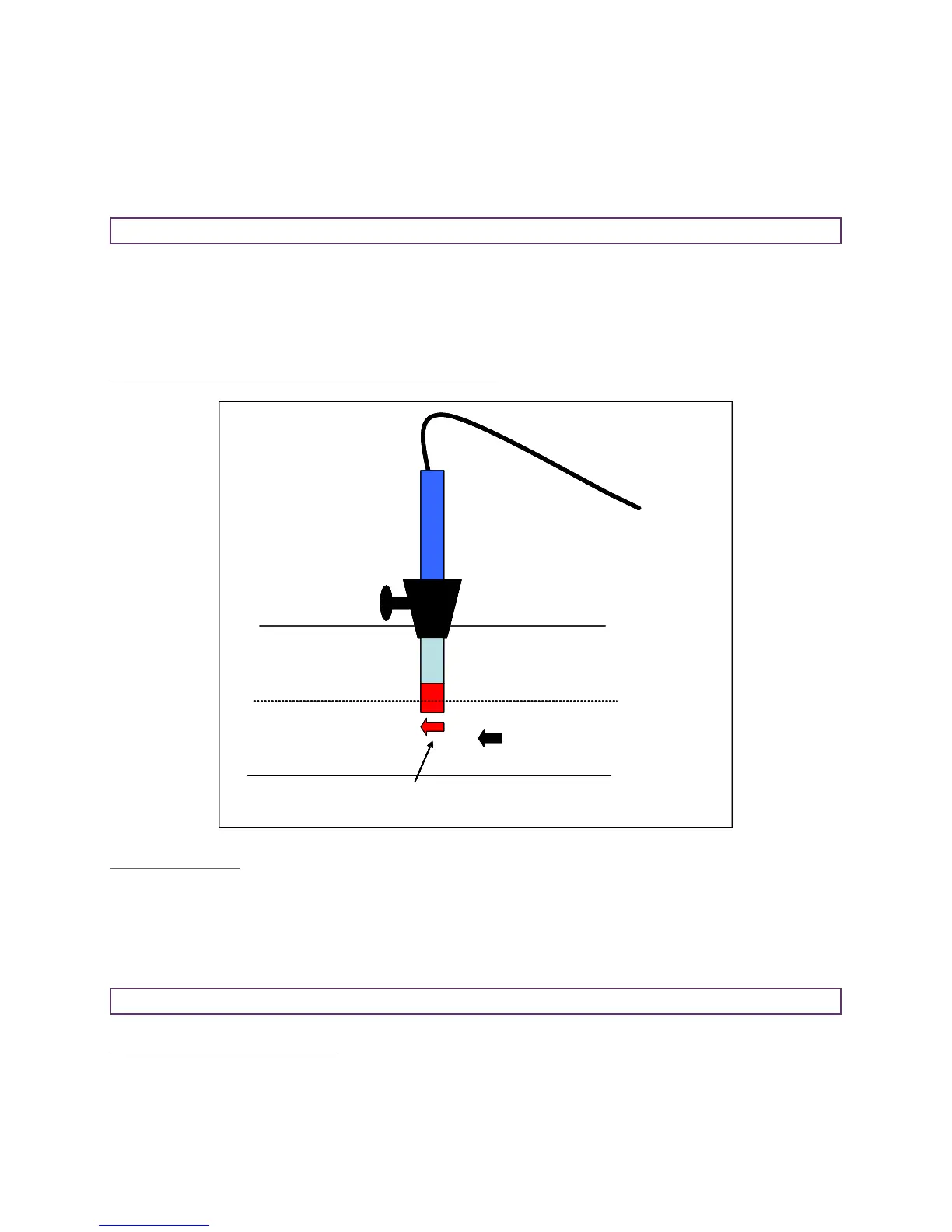

The anemometer must fit centrally (the conical fitting must be set on the probe to half the pipe ID before

insertion). The arrow on the tip of the probe must point in the direction of the gas flow.

Flow readings are most accurate when there is laminar flow (not turbulent). Turbulence can be caused by a

change in pipe direction or restriction. Ideally, upstream you want at least 20 times the pipe ID along the length

of the pipe without restriction or bend. Downstream, you want at least five times the pipe ID along the length of

the pipe i.e. for a 100mm ID you need 2000mm of clear pipe upstream, 500mm downstream.

Example to show anemometer fitting into the sample point:

Instructions for use:

1) Attach the anemometer to ‘Connector C’ (refer to section 5.3 – Instrument connection points).

2) Place the anemometer into the pipe (sample point) ready to take the reading.

3) To take a flow measurement when using an anemometer, follow the instructions displayed on the

analyser. When the reading has stabilised press the ‘Enter’ key to store the reading.

Conical Fitting

Pipe Centre Line

Pipe

Head

Flow Direction

Thumb Screw

Anemometer

Conical Fitting

Pipe Centre Line

Pipe

Head

Direction of the arrow must be in the same direction as the flow

Flow Direction

Thumb Screw

Anemometer

Conical Fitting

Pipe Centre Line

Pipe

Head

Flow Direction

Thumb Screw

Anemometer

Conical Fitting

Pipe Centre Line

Pipe

Head

Direction of the arrow must be in the same direction as the flow

Flow Direction

Thumb Screw

Anemometer

Loading...

Loading...