(Reference European ATEX directive 2014/34/EU)

The following instructions apply to equipment covered by certificate numbers SIRA 11ATEX2197X and IECEx SIR

11.0089X:

The equipment may be used with flammable gases and vapours with apparatus group IIA and temperature

class T1.

The equipment can contain gas sensing heads for the detection of particular gases. The inclusion of a

sensor does not infer that the equipment is suitable for the use of gases with a temperature class of less

than T1.

The equipment is only certified for use in ambient temperatures in the range -10ºC to +50ºC and should

not be used outside this range.

The equipment must not be used in an atmosphere of greater than 21% oxygen.

Repair of this equipment shall be carried out in accordance with the applicable code of practice.

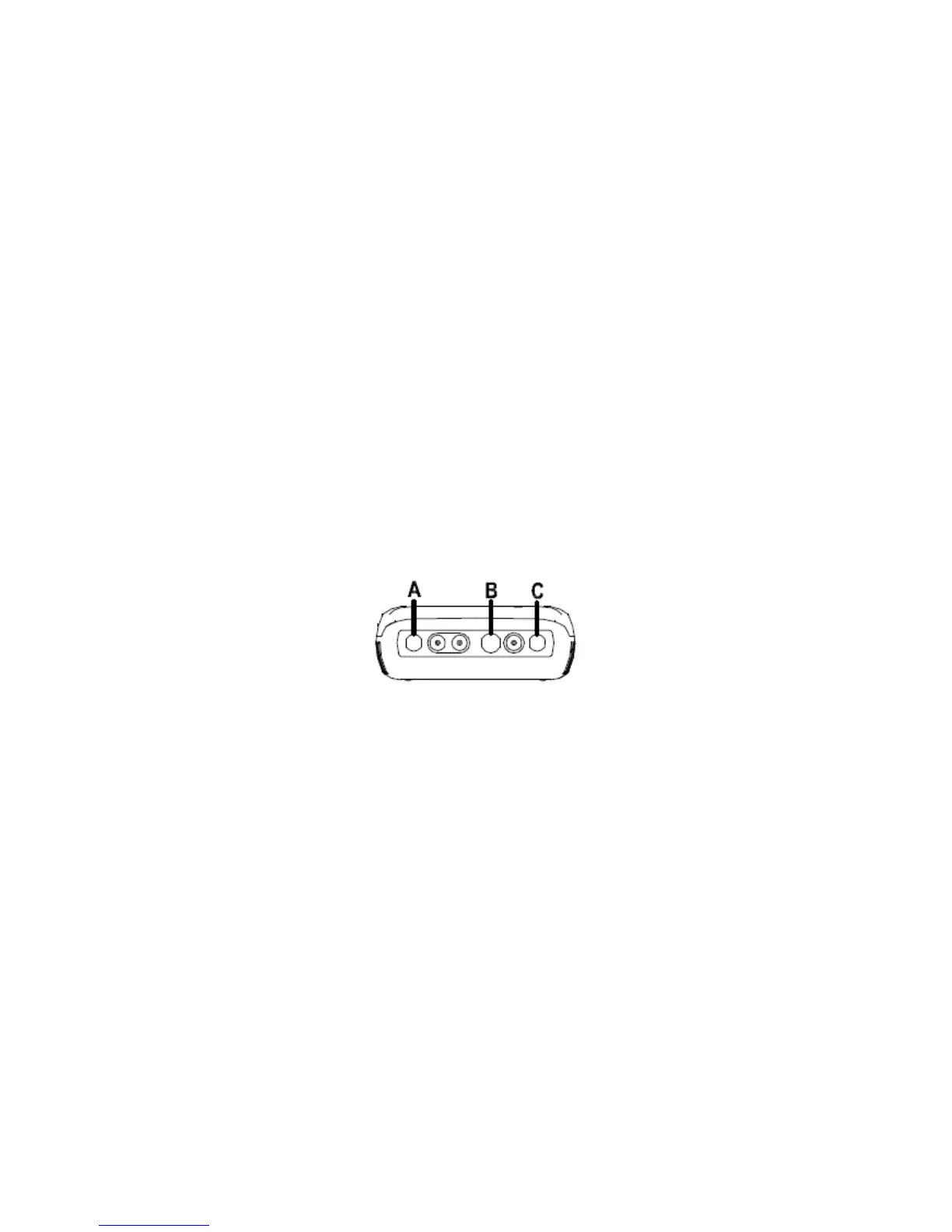

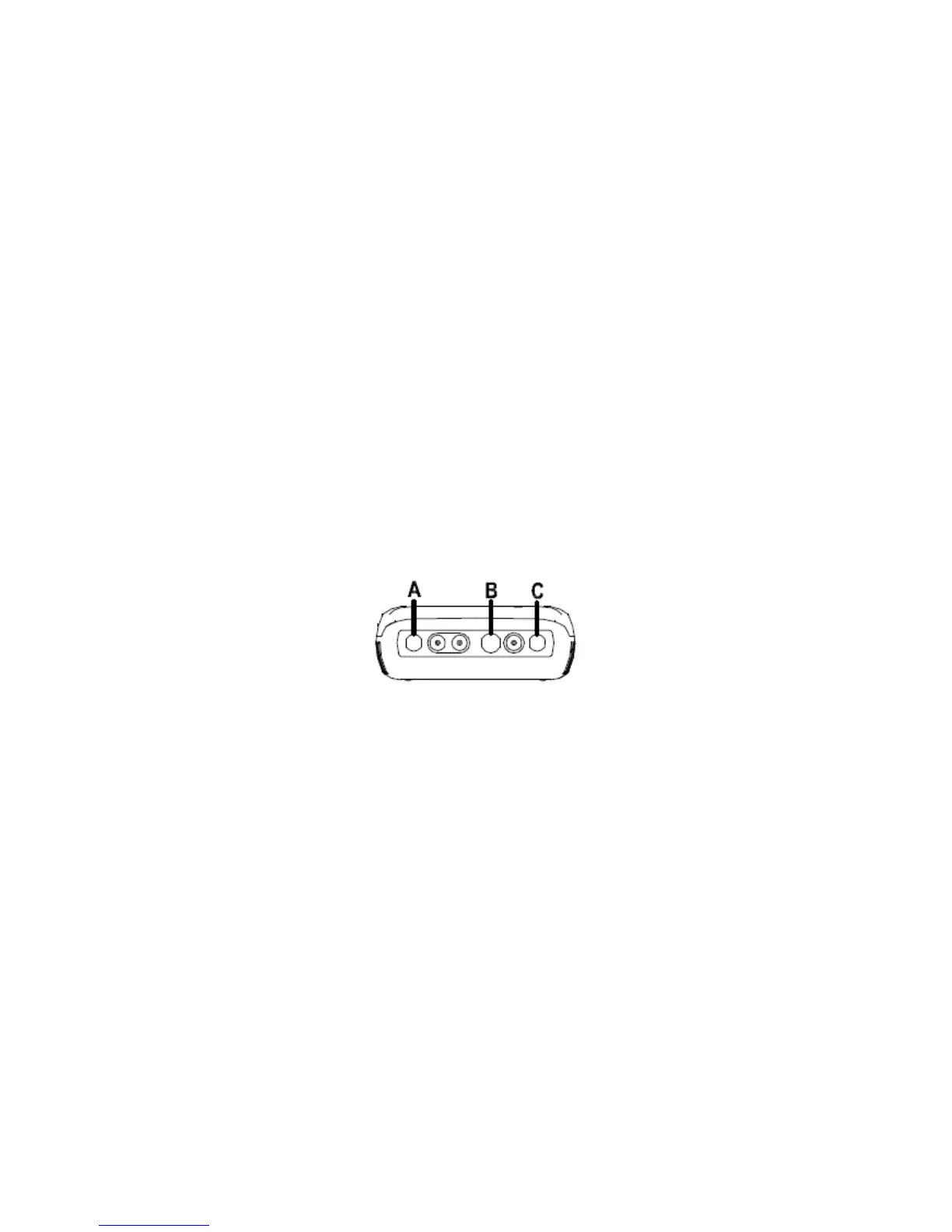

When used in a hazardous area only use GF5.2 temperature probe (SIRA 11ATEX2197X and IECEx

SIR11.0089X). For connector C, the GF5.4 anemometer (BVS 04ATEXE194) for use with ATEX only. The

analyser should not be connected to any other devices in the hazardous area including the GF-USB lead

(connector A) or GF3.9 battery charger (connector B) supplied with the analyser.

Do not charge, recharge or open in a potentially explosive atmosphere.

In hazardous area only use “Temperature Probe GF5.2” in Connector B.

Connector C (Uo=10V,lo=5mA,Po=50mW,Ci=0,Li=0,Co=100uF,Lo=1000mH),

Connector B (Uo=5V,lo=6mA,Po=7mW,Ci=0,Li=0,Co=100uF,Lo=1000mH)

MAXIMUM NON-HAZARDOUS SUPPLIES:

Connector A - Um=6V Connector B - Um=10.1V

The safe area apparatus that is to be connected to the USB Port shall be a Safety Extra Low Voltage (SELV)

or Protective Extra Low Voltage (PELV) circuit.

Only a Geotechnical Instrument battery pack part number 20087 or 2011113 is permitted as a

replacement. This battery pack shall only be changed in a safe area by Geotech personnel or authorised

distributors.

Only Battery Charger type GF3.9 shall be used to recharge the batteries via Connector ‘B’.

If the equipment is likely to come into contact with aggressive substances, e.g. acidic liquids or gases that

may attack metals, or solvents that may affect polymeric materials, then it is the responsibility of the user

to take suitable precautions, e.g. regular checks as part of routine inspections or establishing from the

material’s data sheet that it is resistant to specific chemicals that prevent it from being adversely affected,

thus ensuring that the type of protection is not compromised.

Loading...

Loading...