0020112600_02-10/12-Glow-worm

- 11 -

INSTALLATION

Bypass

Theboileristtedwithanautomaticbypasswhichcanbe

adjustedtosuityoursystemrequirements.

• Ensurethatundernocircumstancesdoestheowratedrop

belowthegurespecied,refertochapter"Technicaldata".

Filling the sealed system

i

The water pressure at the boiler must be at least

1.2bar to operate the lling loop. If the pressure

is less than 1.2bar an external lling loop must be

tted. If this pressure is not available contact the

local water authority.

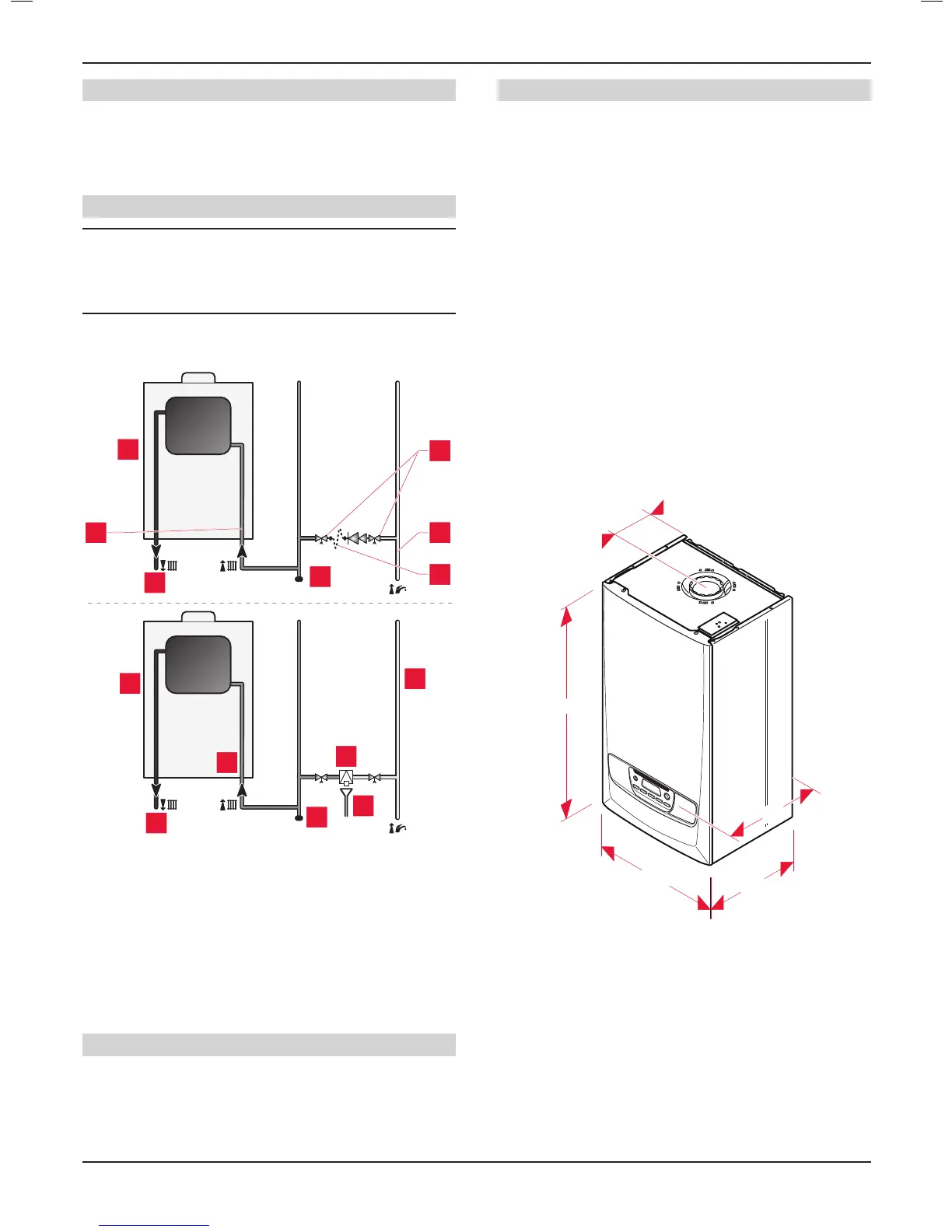

Suitableexternalllingsystemsareshowndiagrammatically,

seediagrambelow.

1

2

3

3

2

1

7

9

8

5

6

5

4

7

Thesystemshouldbepressurisedto0.8bar,indicatedonthe

digitaldisplaywithnoheatingdemand.

Drain points

Draintapsmustbeprovidedatalllowpointsofthesystem,

whichwillallowtheentiresystemtobedrained.

DraintapsshallbetothecurrentissueofBS2879.

Water treatment

-Itisessentialthatpriortoinstallingthenew

boilerthesystemisthoroughlyushed.

-Foroptimumperformanceafterinstallation,the

boileranditsassociatedcentralheatingsystemshouldalsobe

ushed.

FlushingshallbecarriedoutinaccordancewithBS7593,a

chemicalcleansercanbeusedeitherSentinelX300,X400or

FernoxF3aresuitable.

Itisrecommendedtoushexistingsystemsrstbeforetting

thenewboiler.

• Ensureallcleanserisremovedfromthewholesystembefore

addinganinhibitor.

Forlong-termcorrosionprotectionafterushing,aninhibitor

suitableforstainlesssteelheatexchangerscanbeused.Either

SentinelX100orFernoxF1inhibitorcanbeused.

Theboilerissuitableforuseonsystemsusingsoftenedwater.

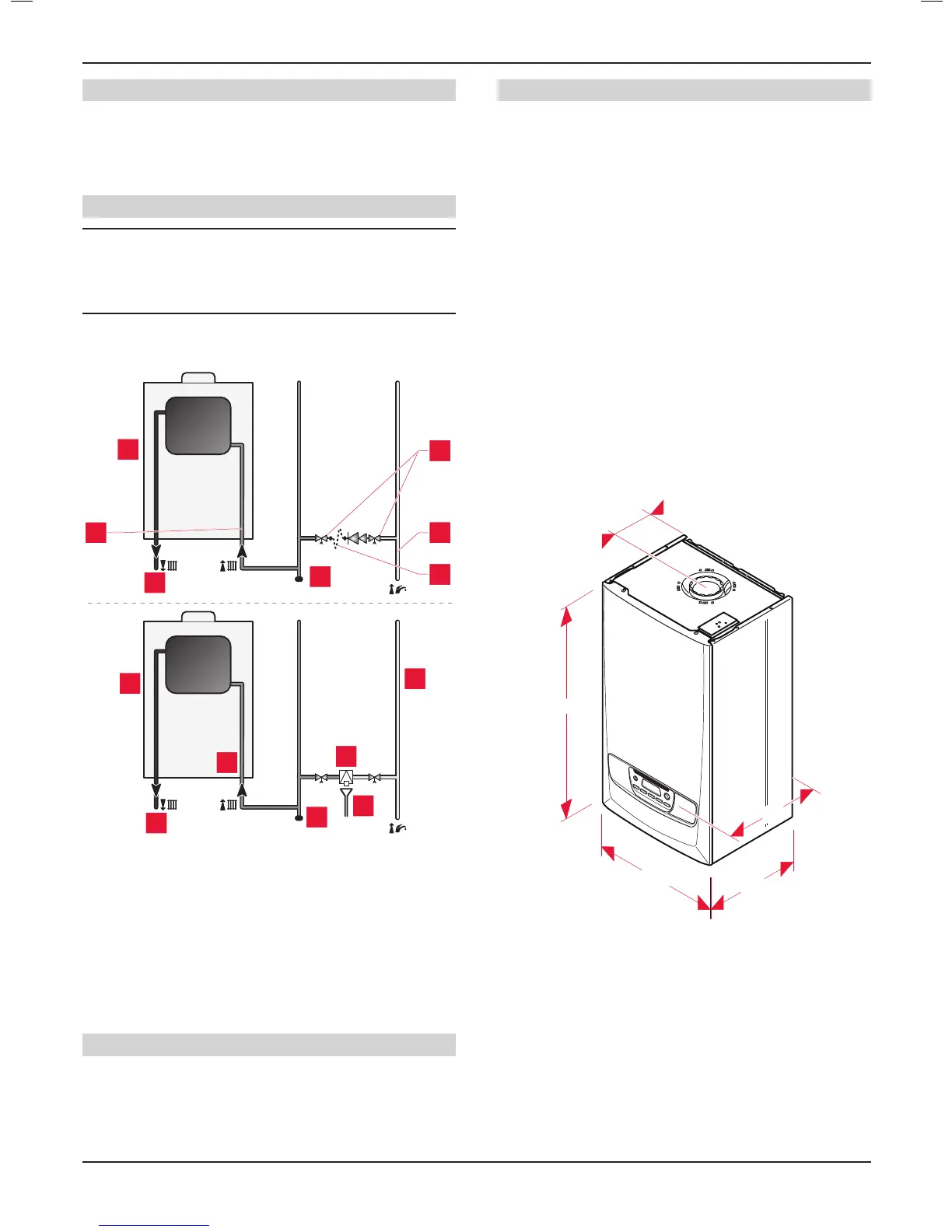

418

344

130

346

740

Loading...

Loading...