GMC-I Messtechnik GmbH 25

Setting Measuring Parameters for RPE

1

SECUTEST BASE10 (feature G01):

Measurement cannot be performed with 10 A AC for this measurement

type.

Entering and Deleting Offset Values

The test instrument determines protective conductor resistance

by means of a 4-pole measurement. If measurement cables or

extension cords are used whose ohmic resistance should be

automatically subtracted from the measurement results, there are

two ways to save the respective offset value in the R

PE

switch

position:

• Entry via the numeric keypad

• Acceptance of the momentary measured value by pressing the

SET OFFSET softkey

Proceed as follows in order to accept the measured value:

➭

Start the measurement and wait until the measured value settles in.

➭ Press the

SET OFFSET

key. The value is transferred to the offset

field.

The entered or accepted offset value is permanently stored and is

subtracted from all protective conductor resistance values mea-

sured in the future. This applies to single measurements as well

as to measurements conducted in the AUTO switch positions.

The symbol is displayed in the header in all switch positions

until the offset value is deleted by pressing the CLEAR OFFSET soft-

key (R

PE

switch position).

Test Sequence with Connection to the Test Socket

➭ Set the rotary switch to the R

PE

position.

➭ Select measurement type or connection type, and test cur-

rent. After pressing the Ip key, you have direct access to the

test current parameters: each time this key is pressed, the

setpoint value shown in the measuring window is switched to

the next value.

➭ Connect the DUT to the test socket.

➭ Start the test: press the START/STOP key.

➭ Contact all conductive parts which are connected to

the protective conductor with test probe P1.

During measurement, the connector cable must only be moved to

the extent to which it’s accessible during repair, modification or

testing.

If a change in resistance occurs during the manual test step of the

continuity test, it must be assumed that the protective conductor

is damaged, or that one of the connector contacts is no longer in

flawless condition.

➭ The measured values are displayed. The measured

value recording symbol shown at the right appears.

Each time this key is pressed, the currently displayed

measured value is saved to the buffer.

➭ Stop the test: press the START/STOP key.

The save symbol appears (floppy disk showing the

number of measured values stored to buffer memory)

and prompts you to save the measured values to an ID

number.

➭ Read the measured values and compare them with the

table of permissible limit values.

➭ Press the ESC key in order to discard the measured

values stored to buffer memory and acknowledge by

pressing the key shown at the right.

Special Case: Testing Extension Cords

➭

Set the measurement type parameter to “PE(TS) – P1”.

➭ Connect the EL1 adapter to the P1 sockets at the test instru-

ment.

➭ Connect the plug at the end of the extension cord to the test

socket.

➭ Connect the coupling socket at the end of the extension cord

to the plug at the EL1 adapter.

➭ Same test sequence as described above.

Further options for testing extension cords are included in the

description of single measurements in the EL1 switch position

and under automatic test sequences in switch position A8.

Special case: permanently installed DUT

➭ Contact all conductive housing parts with test probe P1.

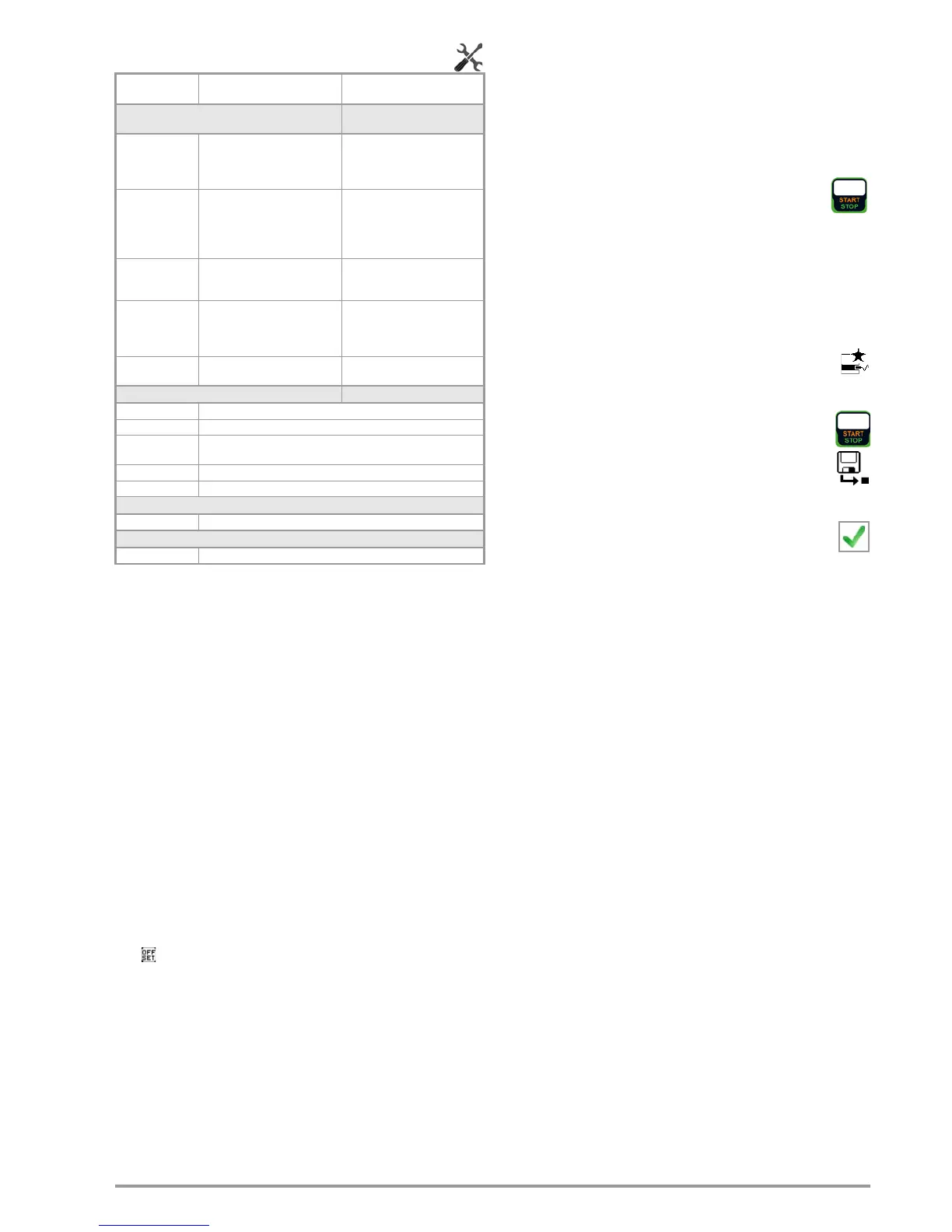

Measuring

Parameter

Meaning

Measurement Type,

Suitable for

DUT Connection via

(passive:) PE(TS)

– P1

Testing is conducted between the

two protective conductor terminals:

at the test socket and test probe

P1.

Test socket, EL1 with DUT at test

socket, VL2E, AT3 adapter (AT3-

IIIE, AT3-IIS, AT3-IIS32),

AT16DI/AT32DI

Active: PE(TS) –

P1

1

Same as PE(TS) – P1, but with

line voltage to the test socket,

200 mA AC flow immediately, as

well as continuously rising DC

test current (PRCDs)

Test socket (for PRCDs)

PE(mains) – P1

permanently con-

nected DUTs

Testing is conducted between the

ground terminal at the mains and

test probe P1.

Permanent connection

P1 – P2

SECUTEST PRO or feature H01:

2-pole measurement between

test probes 1 and 2 (see section

6.6)

Permanent connection

Clamp Test current measurement with

current clamp sensor

Permanent connection

IP(set)

+200 mA DC Test current: positive direct current

-200 mA DC Test current: negative direct current

±200 mA (DC) Test current: direct current whose polarity is reversed every 2 sec-

onds

200 mA (AC) Test current: alternating current

10 A (AC)

10 A test current:

SECUTEST BASE10

or

PRO

only (feature G01)

f – only at 200 mA (AC)

50 ... 200 Hz Test frequency

Offset

> 0 to < 2 Ω Zero balancing for a selected reference point.

Loading...

Loading...