1

T

T

12

B

B

1

2

Station 1

Adjusting Bolt

Station 2

Adjusting Bolt

CF-9 User's Guide

16 GPD Global 09/30/92

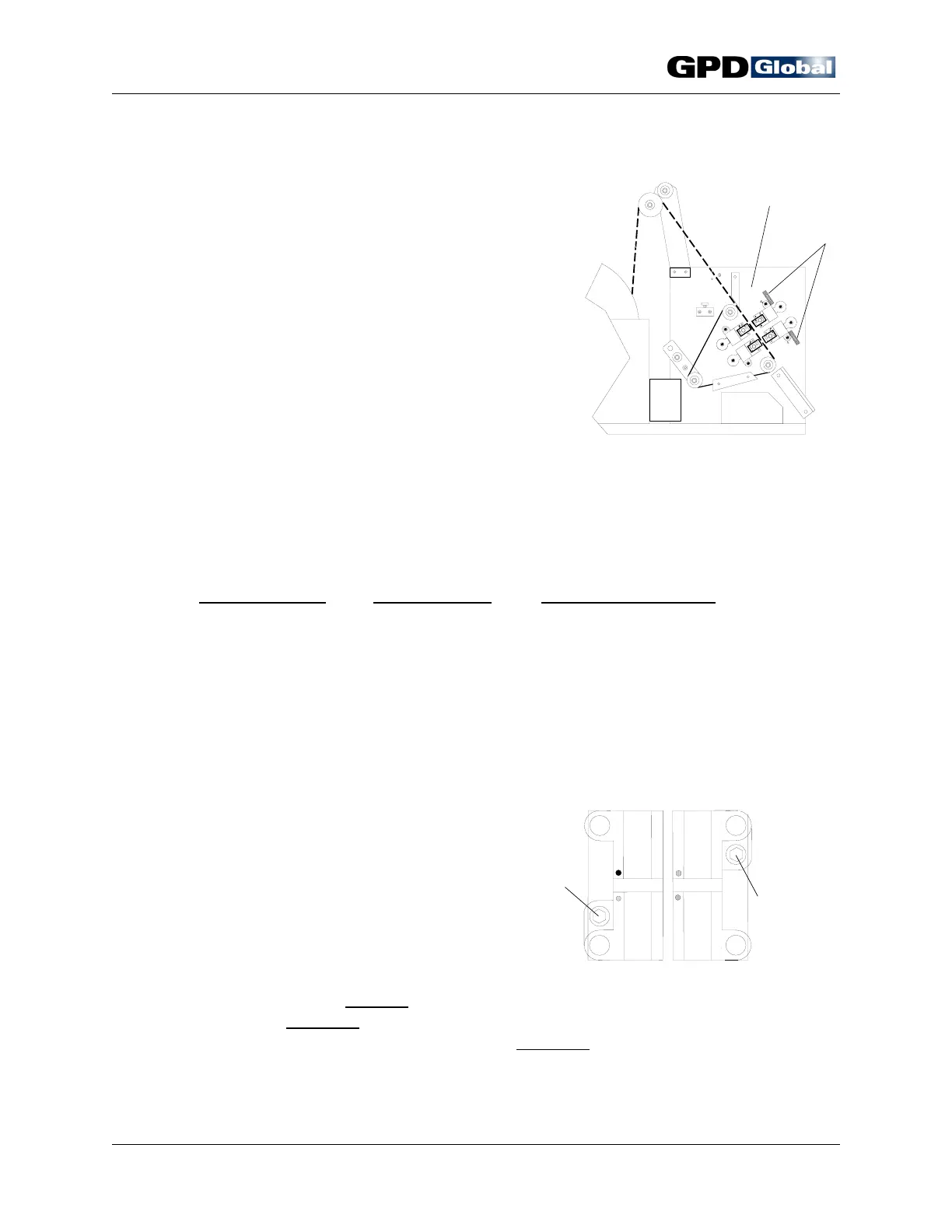

Figure 13 Station Position Adjustment

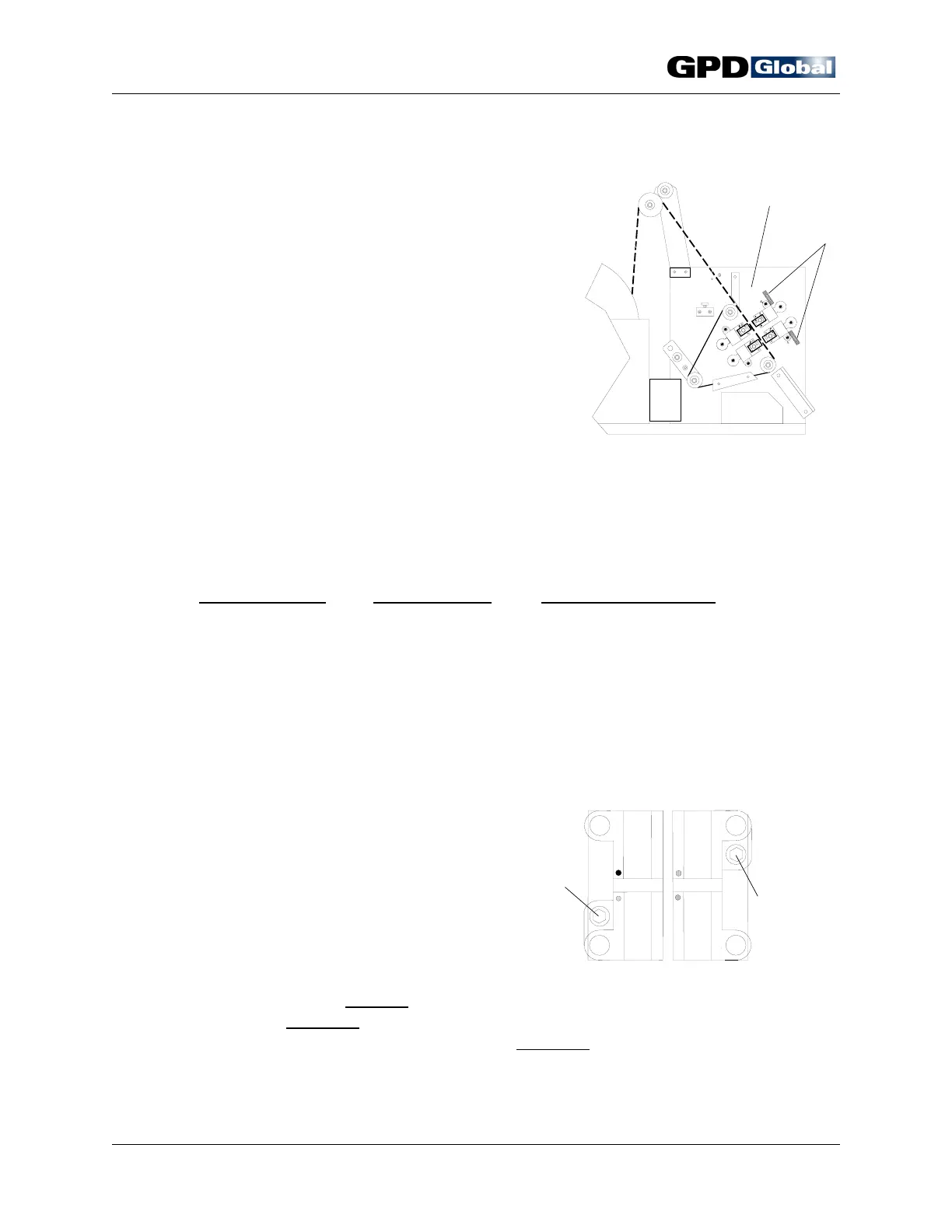

Figure 14

Die Block Assembly Adjusting Bolts

Station Adjustment

The CF-9's die stations are independently

adjustable to control forming and cutting

locations. The action performed on component

leads by each die station can be relocated from

a zero (0) position. GPD suggests setting the

zero (0) reference point at the machine's upright

plate (Figure 13, Item 1). This position also

corresponds with the lead wire point of

attachment to the tape. Refer to Taping

Specifications on page 30.

Backlash is eliminated during station adjustment

by three (3) beveled washers located on each

station adjusting bolt.

The standard micrometer scale (Item 2) attached to each station, indicates the

distance from the component's point of attachment on the tape to the point of station

action on the component lead. These scales are accurate to .0005" (0.0127 mm).

Cut Lead Length

Station Position Station Action Location

Longest Fully retracted Zero (0) position - the point at which

Shortest Fully extended The point as near as possible to the

component attaches to tape.

component body. Each extension

movement of station position creates a

correspondingly shorter lead length.

To adjust station position:

1. Position die block against

machine upright plate.

2. Turn on micrometer scale and

reset to zero (0).

3. Adjust die station using

supplied 1/4" T-handle wrench

in station die block adjusting

bolt (Figure 14).

a. To extend station, turn

wrench counter-

clockwise.

b. To retract station, turn wrench clockwise

.

Loading...

Loading...