T

1

B

1

1.934"

1

2

3

4

5

CF-9 User's Guide

24 GPD Global 09/30/92

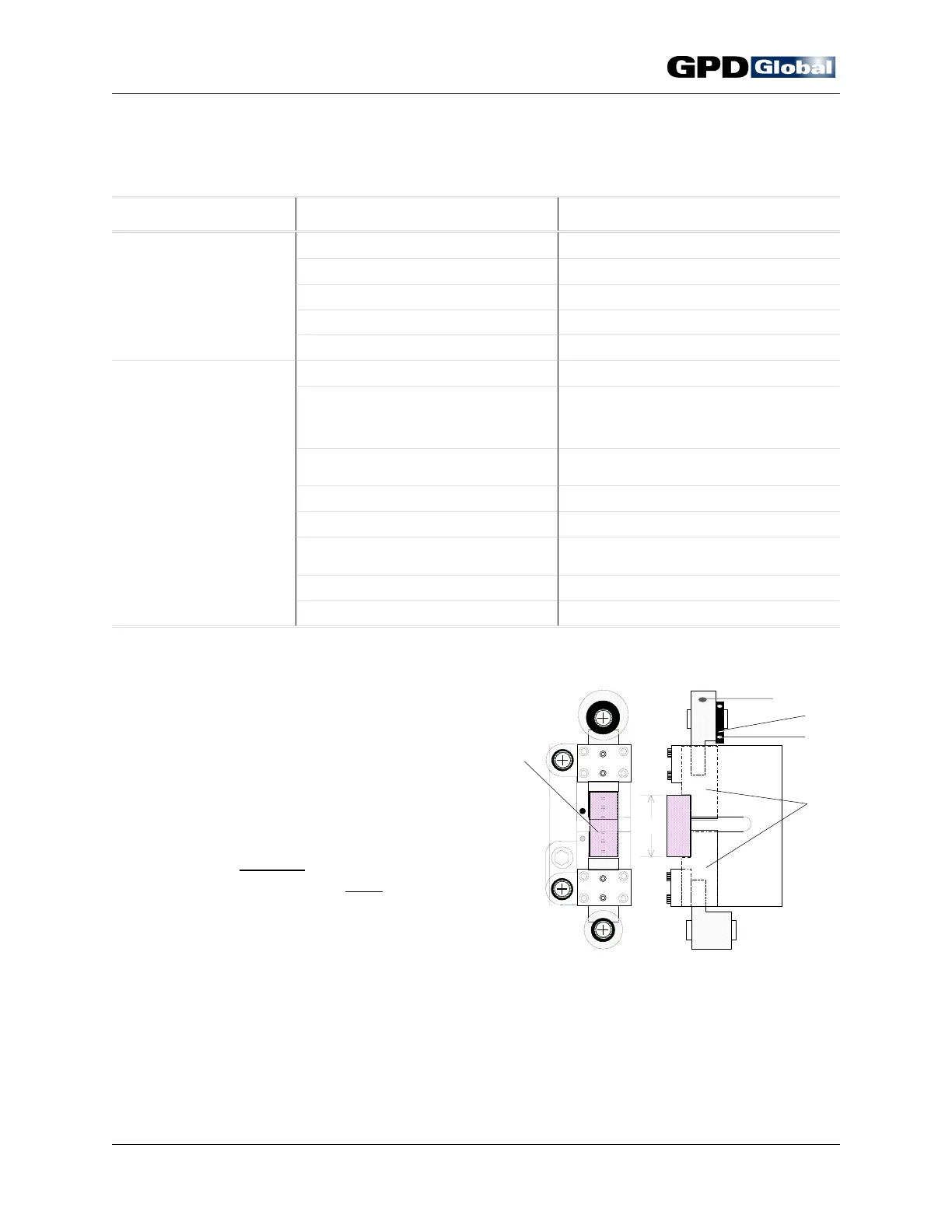

Figure 19

Die Block Assembly Slide Travel

Troubleshooting Guide

(continued)

Problem Possible Cause Action

Machine cutting improperly. Slide clearance too large. Reset slide travel per Slide Clearance.

Incorrect slide gap. Set gap per Slide Travel.

Worn eccentric shaft bushing. Replace bushing.

Worn dies. Replace or repair dies.

Incorrect size screw securing die. Secure die with correct size screw.

No machine movement. Broken drive belt. Replace drive belt.

Blown fuse. Replace fuse.

NOTE: As a preventive measure, turn speed

control to zero (0) before turning machine on.

Power not restored after closing safety Press reset button.

shield.

Machine not plugged in. Plug machine in per Specifications.

Machine not turned on. Turn machine on per Operating Instructions.

Speed control set to zero (0). Set speed control to appropriate operating

speed.

Drive pulley set screws loose. Tighten set screws.

Incorrect size screw securing die. Secure die with correct size screw.

Slide Travel

To adjust slide travel:

1. Unplug machine.

2. Insert provided 1.934" gauge block (Figure

19, Item 1) while manually turning

machine's hand crank until die block slides

(Item 5) are fully closed.

3. Check for gauge block movement. If

movement does not

occur, proceed to Slide

Clearance. If movement does

occur, adjust

the crank adjuster (Item 3):

a. Loosen crank set screws (Item 2).

b. Use wrench in crank adjustor holes

(Item 4) to rotate crank adjuster until

gauge block no longer moves.

c. Tighten eccentric crank screws.

d. Replace bushings if movement cannot be eliminated through adjustment.

Loading...

Loading...