T

1

B

1

T

B

2

2

3

4

3

1

1

2

T

1

B

1

2

CF-9 User's Guide

09/30/92 GPD Global 21

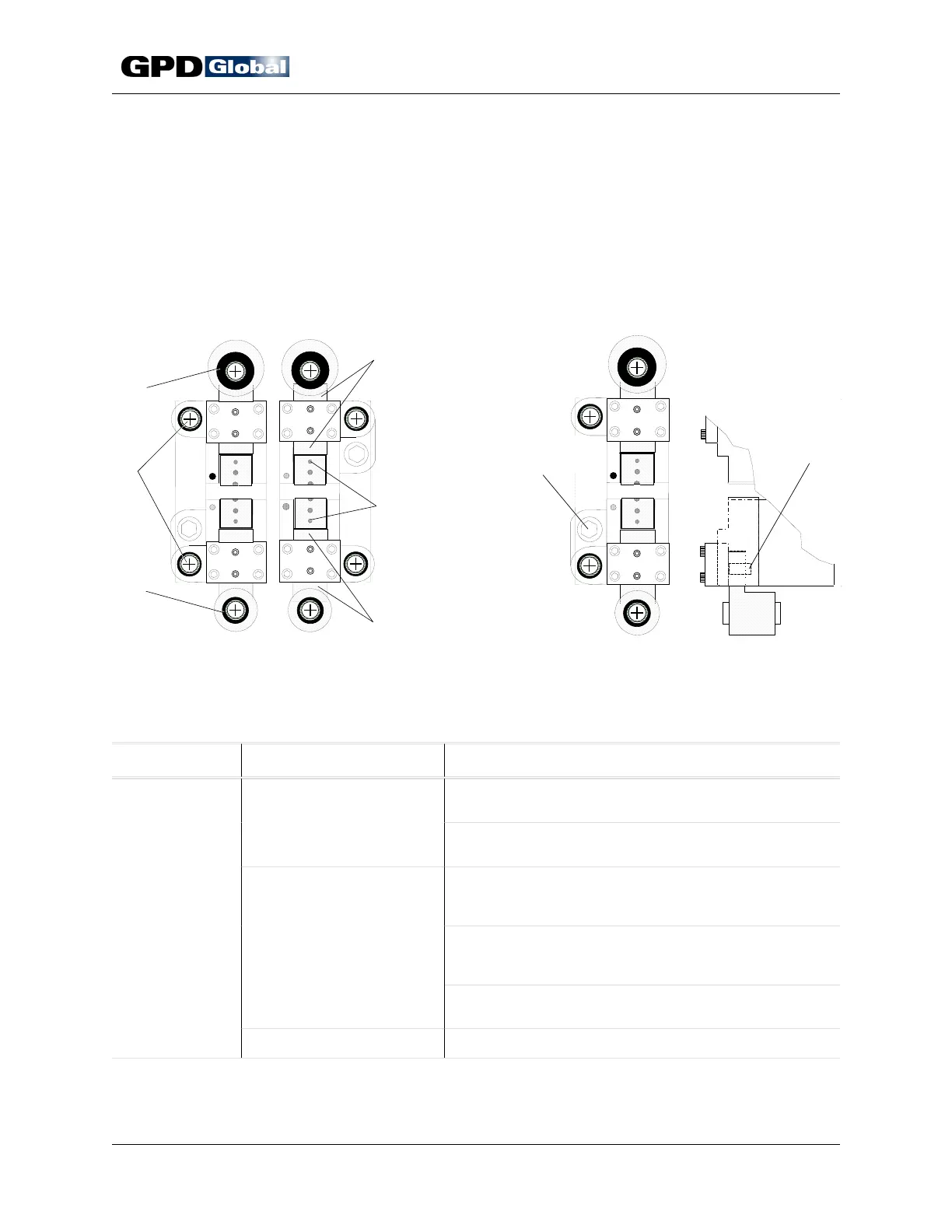

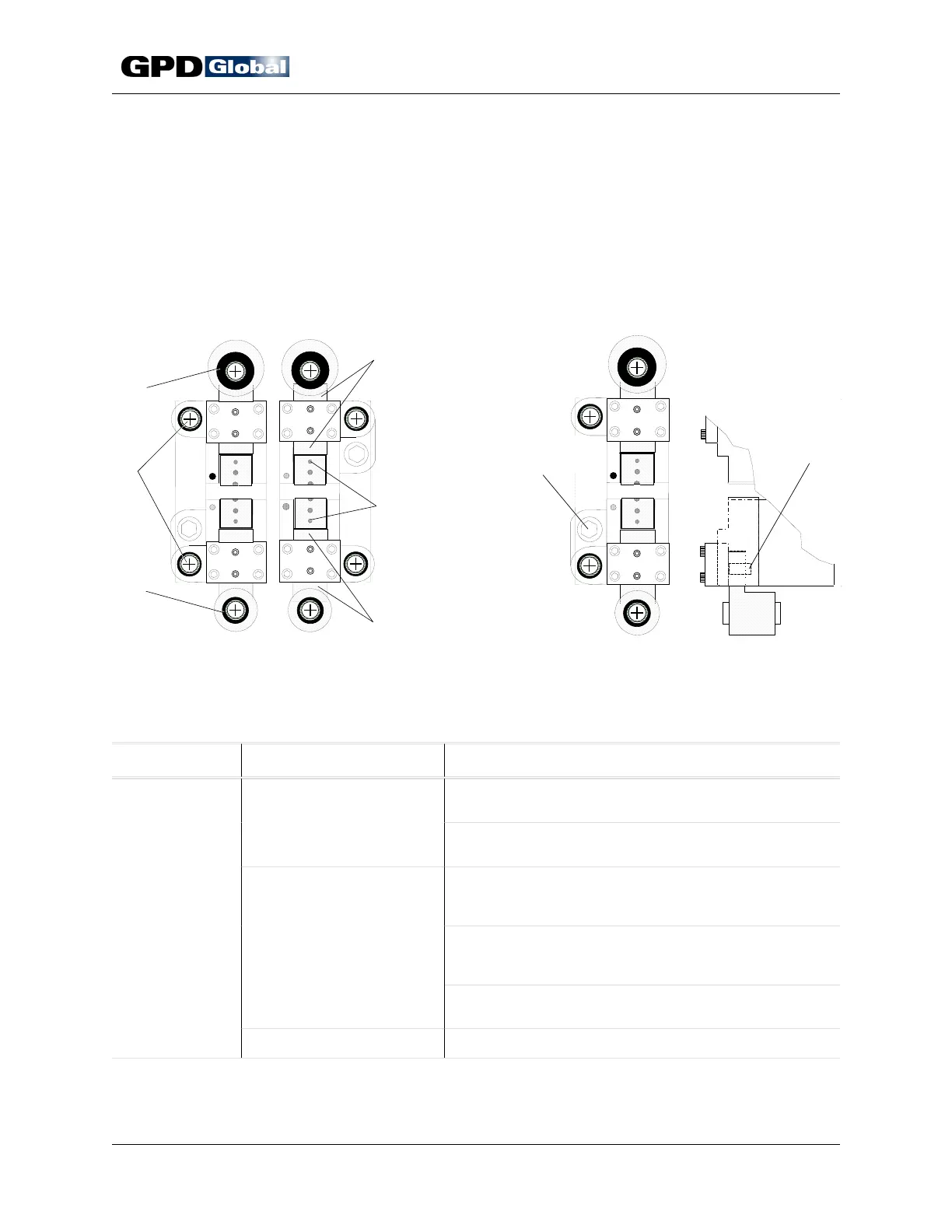

Figure 17 Die Block Assembly Lubrication Figure 18 Die Block Assembly Maintenance

Preventive Maintenance

The preventive maintenance steps in this section are intended primarily for the machine

operator, however, only qualified service or maintenance personnel should perform the steps

requiring access to the machine's cabinet interior. The CF-9 is constructed so that pulleys,

belts, and bearings should not need to be replaced for many years, provided the machine is

used according to instructions.

Preventive Maintenance Schedule

Interval Location Action

Daily Dies/Knives Remove all dies/knives, inspect for wear, and clean

(8 hours of with rust inhibitor.

operation)

Inspect for foreign matter or dust build-up. Brush

clean.

Die Block Assembly Inspect and lubricate eccentric shafts and bushings

(Figure 17, Item 1) and die block guide shafts (Item 2)

with a light machine oil (3-in-1).

Place a drop of light machine oil (3-in-1) on slide

surfaces (Figure 17, Item 3) and in lubrication hole

(Item 4).

Apply oil to each of the four crank pins (Figure 18, Item

2).

Drive Belt Inspect belt pins and cogs for wear.

Schedule continues on following page.

Loading...

Loading...