T

1

B

1

9

8

1

2

3

4

5

CF-9 User's Guide

09/30/92 GPD Global 25

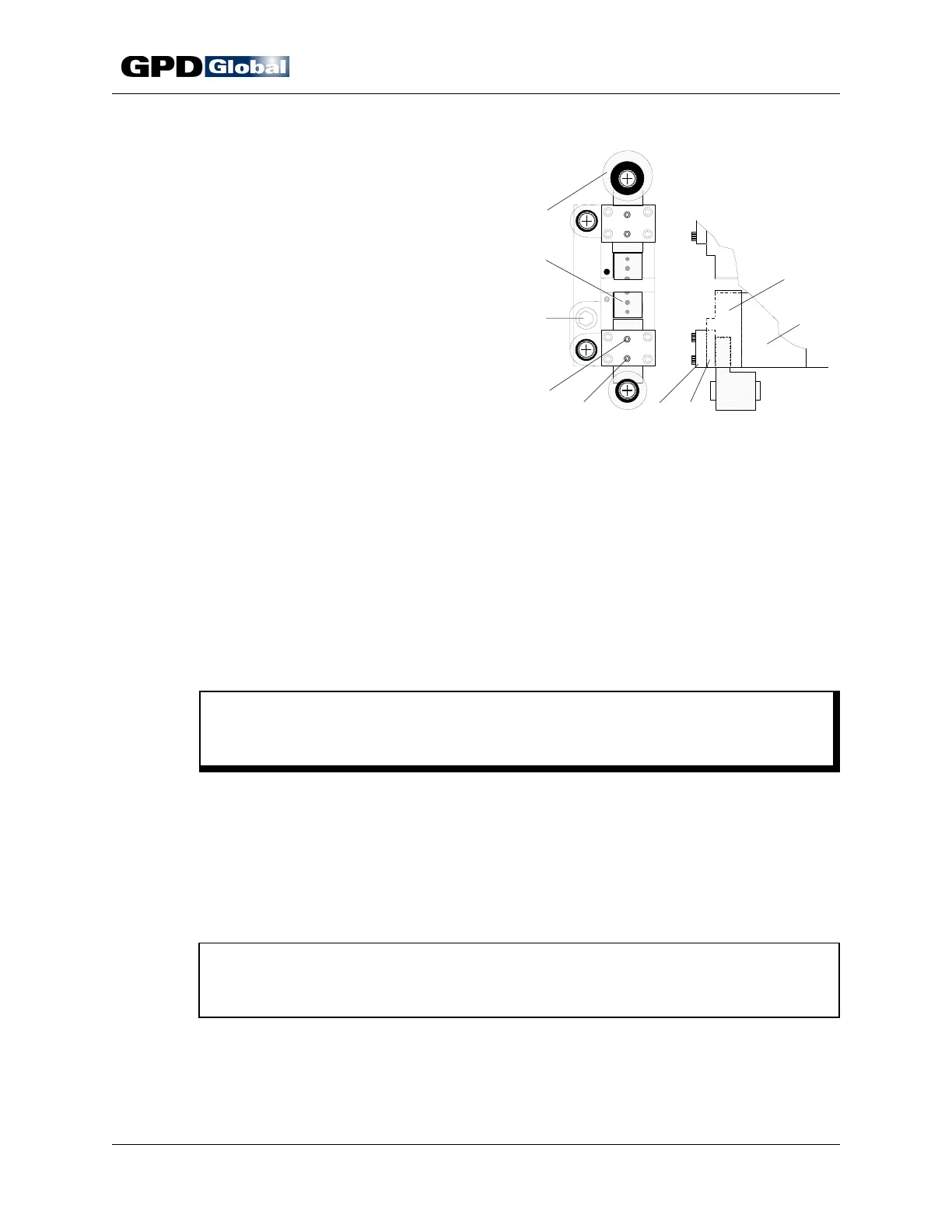

Figure 20 Die Block Assembly Slide Clearance

Slide Clearance

To adjust slide clearance:

1. Remove die block assembly. Station 1 die

block assembly is illustrated in Figure 20.

a. Remove from the CF-9:

• Tape exit chute

• Component transfer belt

• Transfer belt guide and

component tape pressure plate

(located on either side of

transfer belt)

b. Raise die block approximately 1"

(25.40 mm) from machine upright

plate using machine's die block

adjusting bolt (Figure 20, Item 3).

c. Remove mounting screws from micrometer scale's lower mounting block.

d. Turn die block adjusting bolt until die block no longer moves and then slide die block

straight off machine.

2. Clean parts.

a. Remove and discard set screws in cover plate (Figure 20, Item 6).

b. Remove slide (Item 9) from die block.

c. Use a degreaser (brake cleaner) to remove all oil from slide, die block, and wear

plate (Items 9, 8, and 7).

C A U T I O N

Do not expose micrometer scales to degreaser (brake cleaner) as it clouds the

clear face plate.

d. Measure all surfaces for wear and inspect for scratches and gouges. Replace parts

if raised material is visible on working plane.

e. Lightly stone all surfaces.

f. Blow dry all parts.

3. Reassemble die block.

a. Install slides in die block.

NOTE

Position slide with the eccentric bushing in the eccentric crank (Item 1) in die

block's top half (T1 or T2).

b. Slip wear plate face up between cover plate and slide.

c. Align wear plate counter sunk holes with cover plate set screws.

d. Install new set screws and lightly tighten.

e. With slides in closed position, locate a dial indicator on die mounting surfaces (Item

Loading...

Loading...