1

2

3

CF-9 User's Guide

09/30/92 GPD Global 17

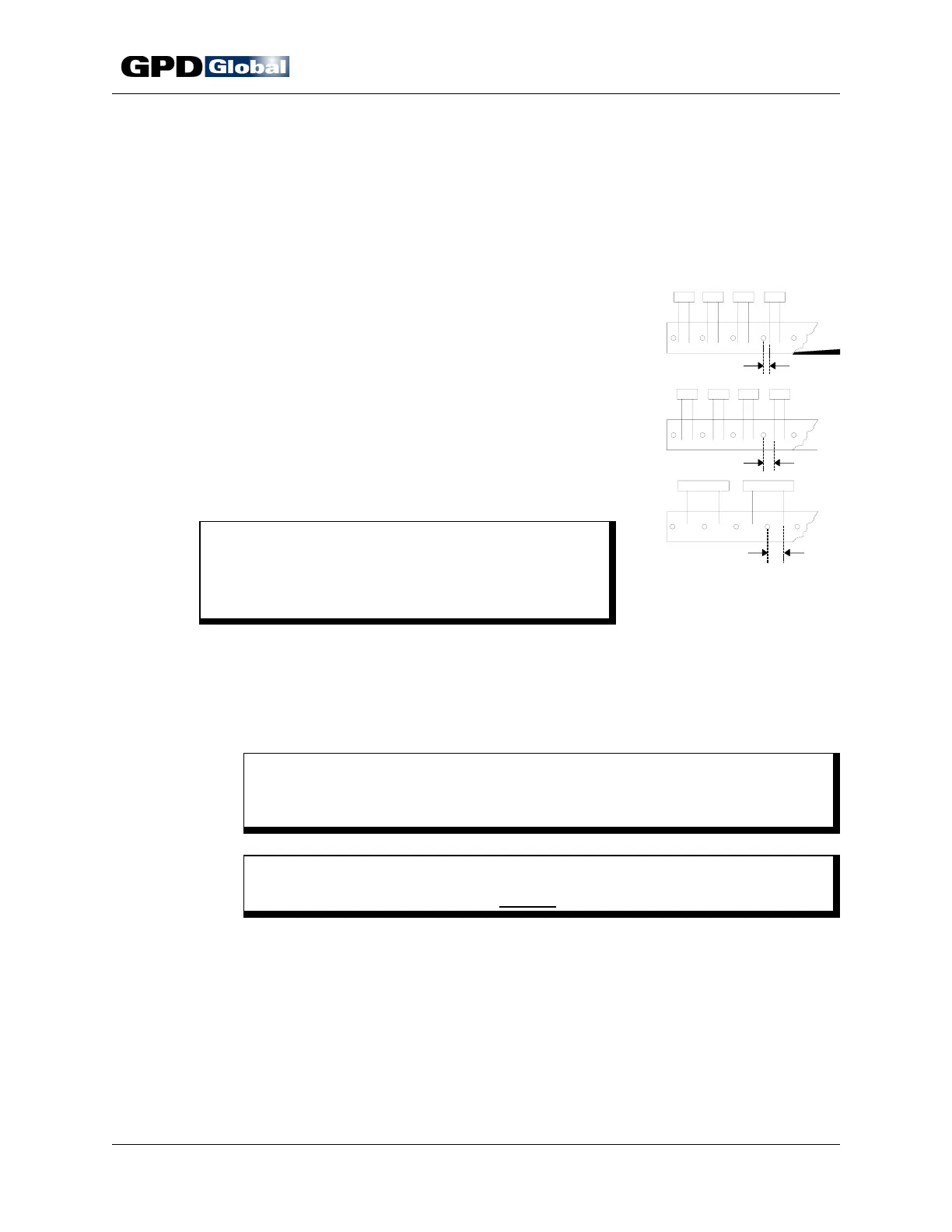

Figure 15 Component

Position Relative to Tape Hole

4. Record your micrometer setting. Then machine can be setup quickly the next

time you process the same component type.

5. Repeat Station Adjustment procedure for remaining die station.

Component Alignment

The CF-9 indexes exactly 1/2" (12.70 mm) every time,

however, component position relative to the tape hole

may vary from your last run due to variances between

vendors or lots because:

• Distance from tape hole to component lead wire

may vary (Figure 15, Item 1).

• Tape hole may be located between or under

component (Items 2 & 3).

A variance requires readjusting component alignment

with die stations — a simple matter of repositioning a

pulley (Figure 16, Item 4).

C A U T I O N

Testing component position relative to dies

MUST be done prior to automatic machine

operations.

To align components with die stations:

1. Manually index machine with hand crank just until components are centered

between dies and just before die touches component wires. Turn hand crank

slowly while visually inspecting for the relative position between components

and tape holes.

C A U T I O N

Dies should just start coming together - they should NOT be closed or

touching component.

C A U T I O N

DO NOT rotate mechanisms in reverse to check timing.

2. Loosen bolt in drive pulley (Figure 16, Item 4) with supplied 3/16" wrench.

3. Manually turn pulley in either direction to centrally position a component

between each die station.

4. Lock pulley in its new position by re-tightening the bolt.

5. Repeat step 1 to recheck tape alignment.

Loading...

Loading...