Maintenance

Pump Pump

Pump

Lubrication Lubrication

Lubrication

System System

System

ChecktheconditionoftheISOpumplubricant

daily.Changethelubricantifitbecomesagel,

itscolordarkens,oritbecomesdilutedwith

isocyanate.

Gelformationisduetomoistureabsorption

bythepumplubricant.Theintervalbetween

changesdependsontheenvironmentin

whichtheequipmentisoperating.Thepump

lubricationsystemminimizesexposureto

moisture,butsomecontaminationisstill

possible.

Lubricantdiscolorationisduetocontinual

seepageofsmallamountsofisocyanatepast

thepumppackingsduringoperation.Ifthe

packingsareoperatingproperly,lubricant

replacementduetodiscolorationshouldnotbe

necessarymoreoftenthaneverythreeorfour

weeks.

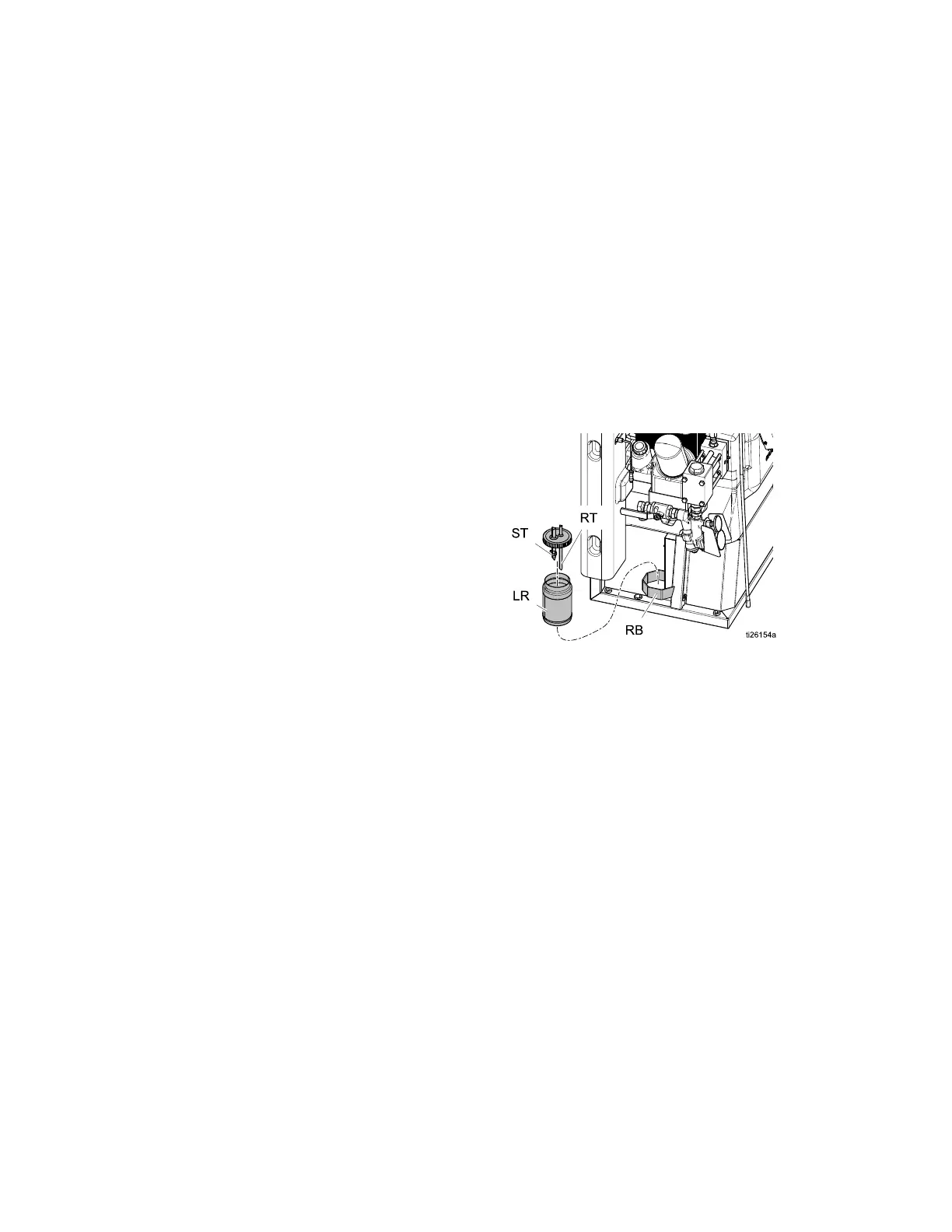

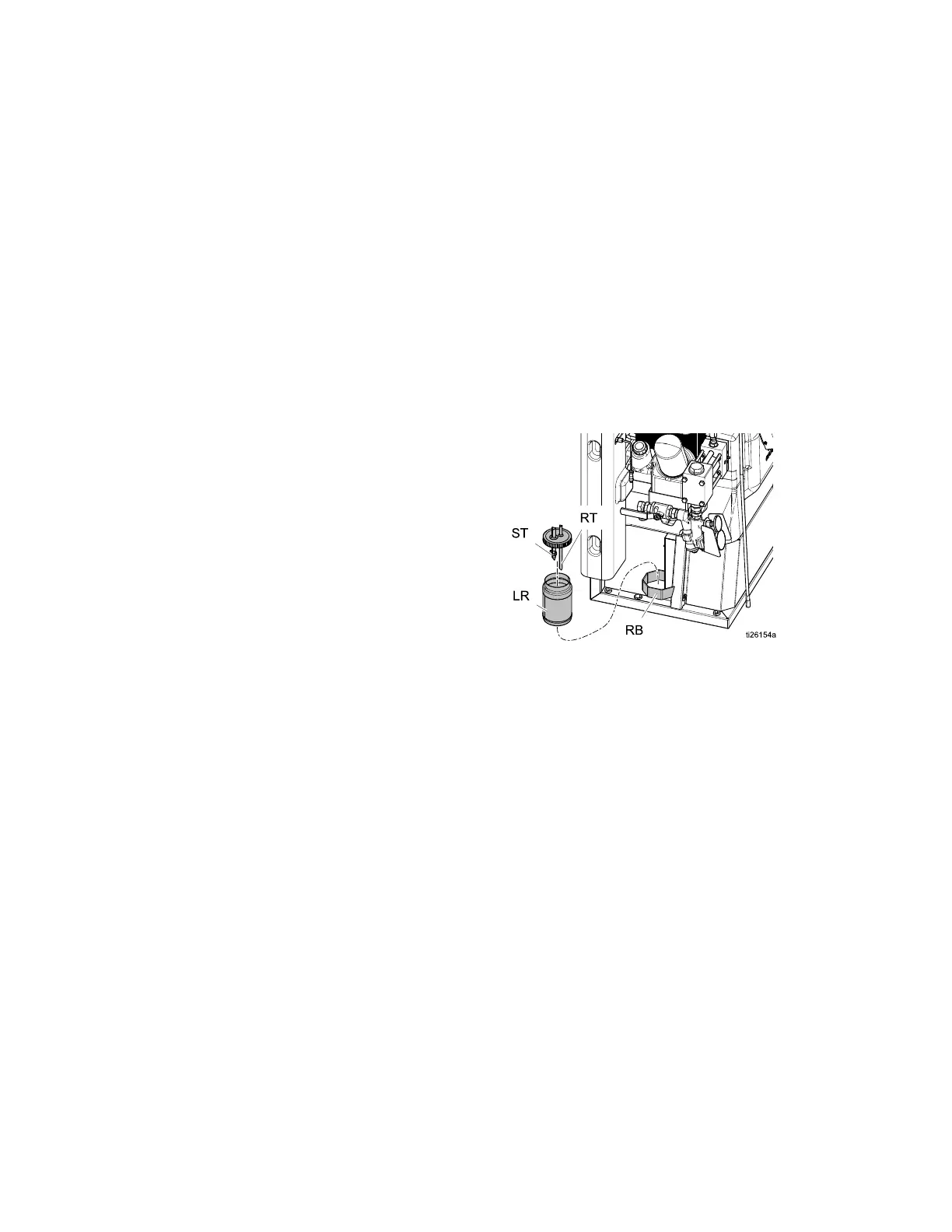

Tochangepumplubricant:

1.FollowPressureReliefProcedure,page62.

2.Liftthelubricantreservoir(R)outofthe

bracketandremovethecontainerfrom

thecap.Holdingthecapoverasuitable

container,removethecheckvalveandallow

thelubricanttodrain.Reattachthecheck

valvetotheinlethose.

3.Drainthereservoirandushitwithclean

lubricant.

4.Whenthereservoirisushedclean,llwith

freshlubricant.

5.Threadthereservoirontothecapassembly

andplaceitinthebracket.

6.Pushthelargerdiametersupplytube(ST)

approximately1/3ofthewayintothe

reservoir.

7.Pushthesmallerdiameterreturntube(RT)

intothereservoiruntilitreachesthebottom.

NOTE: NOTE:

NOTE:

Thereturntubemustreachthe

bottomofthereservoirtoensurethat

isocyanatecrystalswillsettletothebottom

andnotbesiphonedintothesupplytube

andreturnedtothepump.

8.Thelubricationsystemisreadyforoperation.

Noprimingisrequired.

66 333023U

Loading...

Loading...