syncFURNACE OD Instruction & Installation Manual – Rev 09 Pg. 62 of 81

11. TROUBLESHOOTING >

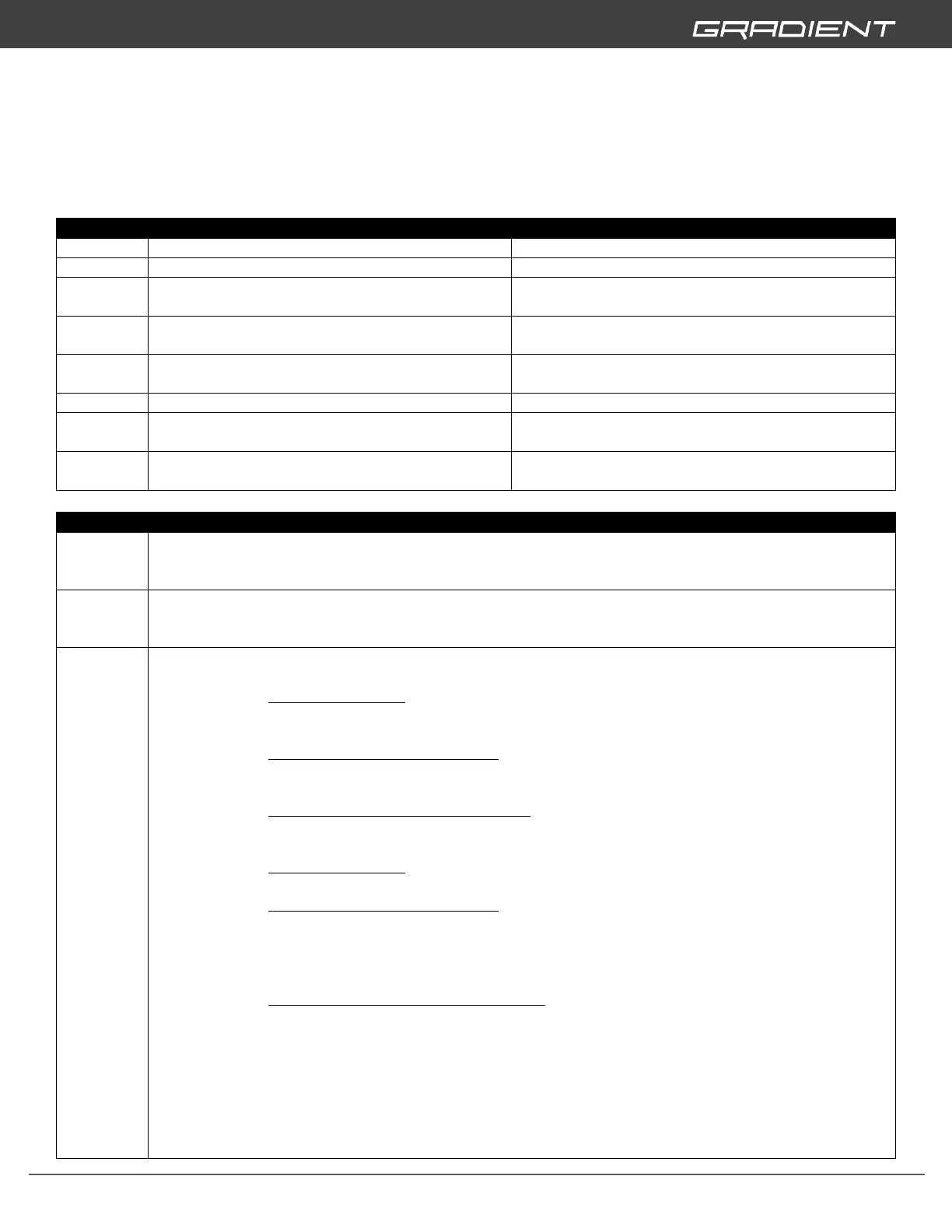

syncFURNACE OD has built in fault protection. Below is a list of the fault codes built into the controller

and the corrective action required to place the product back into normal operation. Note: the controller

screen color will turn red when a fault has occurred.

Potential Fault Codes:

No RPM from Comb Blwr @ Startup

Lockout – Manual Heat Demand Reset Only

Lockout – Manual Heat Demand Reset Only

No Power @ Ignition (Hi-Limit Safety Open)

Lockout for 1hr, Auto Reset – Max 3 Trials per

Day, Reset Daily

Ignition Mod Lockout – Burner Fail to Ignite

Lockout for 1hr, Auto Reset – Max 3 Trials per

Day, Reset Daily

Flame Failure During Burner Operation

Lockout for 1hr, Auto Reset – Max 3 Trials per

Day, Reset Daily

Flame Detected After Gas-Valve Shut-off

Lockout – Manual Heat Demand Reset Only

No Flow Detected After Demand Turned On

Lockout – Manual Heat Demand Reset Only

Low Water Heater Fluid Pressure Detected

Lockout – Demand Reset Only When Water

Heater Fluid Filled & Re-pressurized

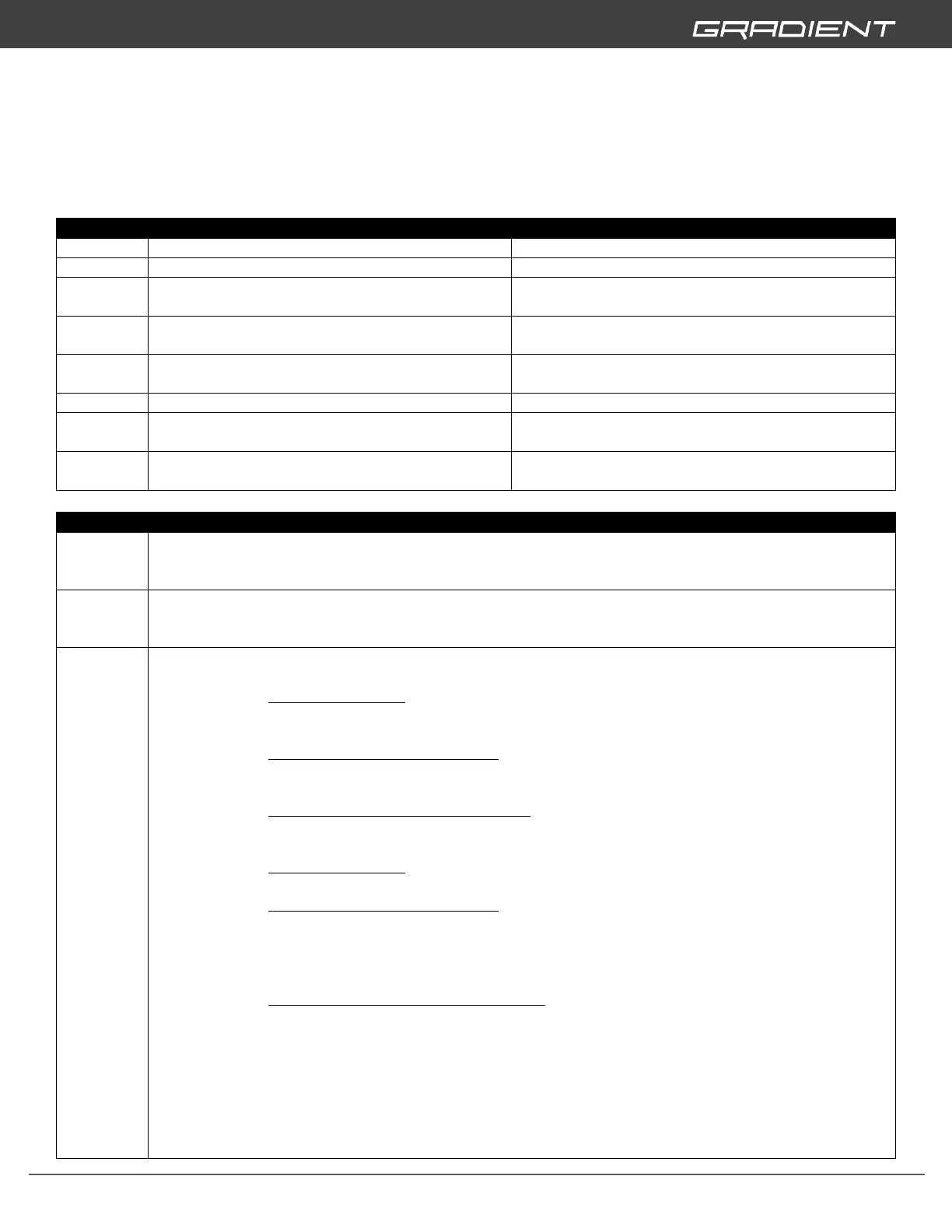

1. Check for partially or fully blocked chimney system

2. Check wiring at combustion blower, verify both low voltage control & main power

3. Identify & replace failed component – wiring, combustion blower and/or controller

1. Check for partially or fully blocked chimney system

2. Check wiring at combustion blower, verify both low voltage control & main power

3. Identify & replace failed component – wiring, combustion blower and/or controller

1. Identify which/if high-limit safety has opened – verify wire harness continuity –

**NOTE: safeties are connected to HIGH VOLTAGE LINE (115Vac)**

a. Vent Limit Switch – Heat exchanger temperature above switch setpoint –

Switch is NOT resettable, DO NOT BYPASS – Heat exchanger must be

replaced – Contact Gradient Thermal Inc.

b. Water Supply Hi-Limit Switch – Actual supply water temperature above switch

setpoint – Hi-Limit switch will auto-resets once temp drops 10°F below

setpoint

c. Condensate Trap Pressure Switch – Undersized drain or partial or full trap

blockage

2. Corrective action for limit switch –

a. Vent Limit Switch – Contact Service/Repair Contractor & Gradient Thermal

Inc.

b. Water Supply Hi-Limit Switch –

i. Check for pump(s) failure

ii. Check combustion blower, does it only run at MAX speed?

iii. Check the load of the heating zone, is the installation sized properly?

iv. Check pressure and supply sensor for failure

c. Condensation Trap Pressure Switch –

i. Ensure proper size & slope of condensation drain

ii. Check internal condensation trap for partial or full blockage

iii. Clean trap and remove all blockages from heat exchanger outlet to

floor drain

iv. Test and visually inspect to ensure free flowing condensate to drain

3. If all safeties are closed and not receiving power, check controller to see if its

applying power to the safety line / ignition module as per internal wire diagram.

4. Verify function of ignition module and flame sensor / spark ignitor

Loading...

Loading...