syncFURNACE OD Instruction & Installation Manual – Rev 09 Pg. 30 of 81

GAS LINE CONNECTION:

Gas-line sizing and the connection to syncFURNACE OD must be made in accordance with current edition

of codes CAN/CSA B149.1 or .2, or National Fuel Gas Code ANSI Z223.1/NFPA 54, as well as local codes

where applicable. All gas piping and connections must be completed by a qualified gas-fitter.

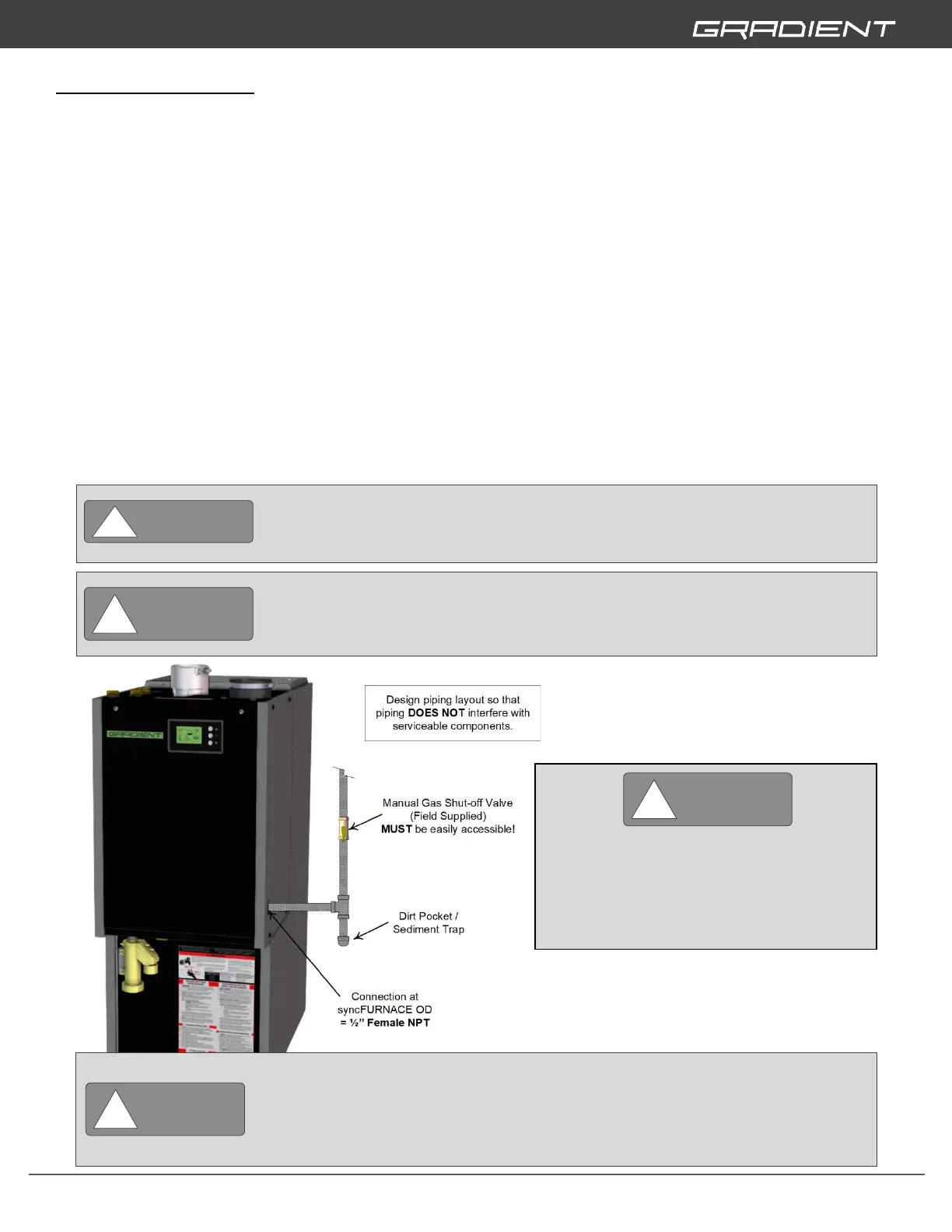

Install gas-line with a manual shut-off valve (listed by a nationally recognized testing lab) and 3” (76mm)

dirt pocket or sediment trap ahead of the gas-line connection fitting on syncFURNACE. Ensure that gas-

line is properly supported so to not apply load to the connection.

Consult local codes and regulations to determine proper gas-line pipe size (connection onto syncFURNACE

OD is ½” Female NPT). Size must be determined based on – pipe length, number of fittings and the

maximum input requirements of all the gas appliances connected to the gas-line used in the building.

After completion of gas-line piping to the product, perform pressure test to ensure no leaks are present

throughout the system – including thru internal gas piping components inside syncFURNACE OD. DO NOT

apply pressure greater than 13.5 inch W.C. (33.6 mbar) to gas components inside the product.

Identify manual gas shut-off valve with a label and metal tab and familiarize end user of its location and

proper operation for service or in case of an emergency.

Gas line installation must be completed by an individual that is licensed for gas

installations.

The gas-line must be independently supported so that it does not apply any load to

the gas connection fitting on syncFURNACE OD.

It is the installer’s responsibility to ensure that syncFURNACE OD and all other gas

appliances sharing the gas supply line must be firing at maximum capacity to

properly measure the inlet supply pressure. Low gas pressure could be an

indication of an undersized gas line, an undersized gas meter, a faulty regulator

and/or obstructed gas supply line. No noticeable gas pressure drop in the gas line

can occur when any unit (or combination of units) lights or runs.

DO NOT apply pressure greater than 13.5 inch W.C. (33.6 mbar) to gas components

inside syncFURNACE OD. Failure to comply will null and void product warranty.

Do not use an open flame to test for gas leaks. Failure to follow these instructions

may result in fire, property damage, serious injury or death.

syncFURNACE OD is factory equipped to

operate using either NATURAL GAS or

LP (PROPANE) – consult the product

rating plate to confirm its setup for the

type of gas being used in your project.

Loading...

Loading...