Model G0452/P/Z (Mfg. Since 08/12)

-23-

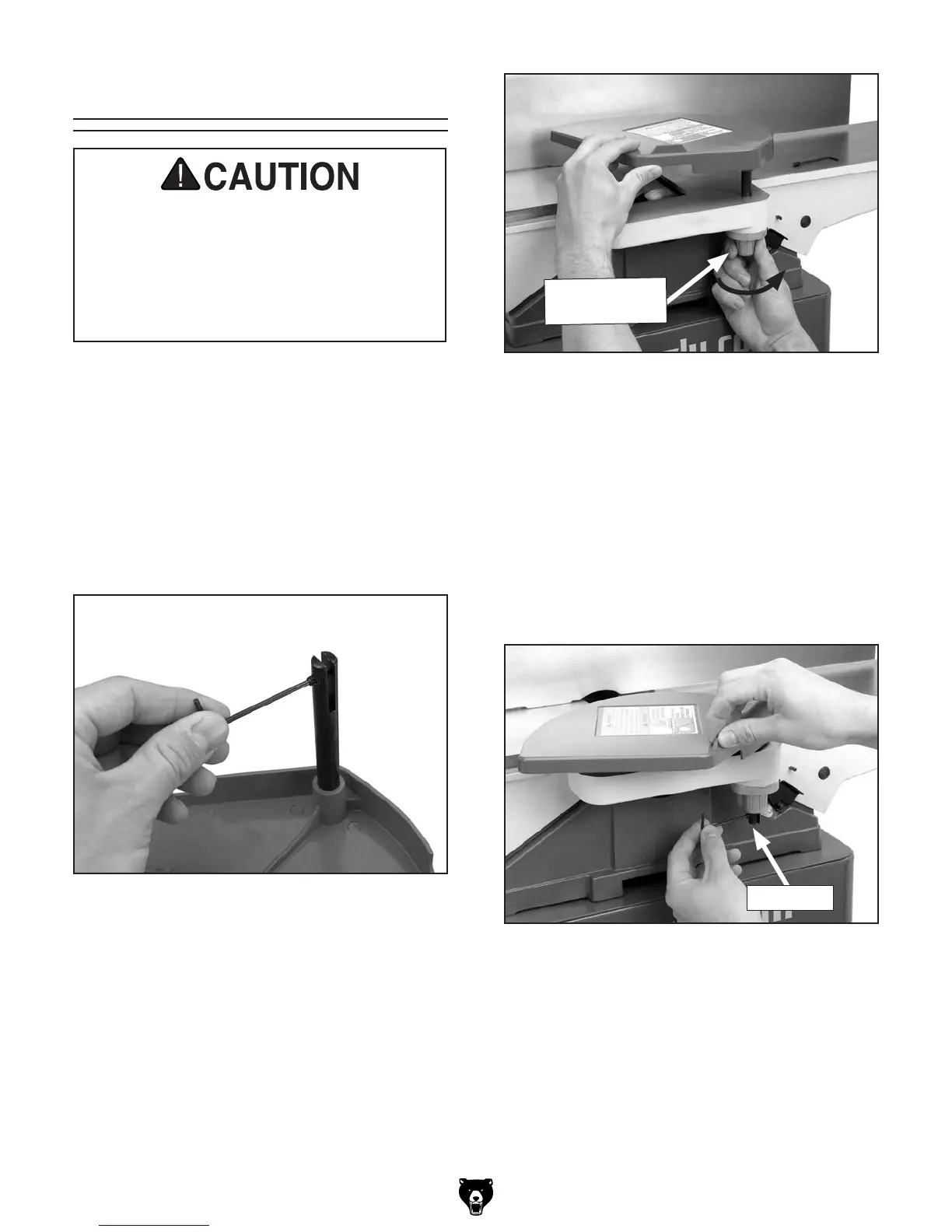

Figure 22. Set screw location.

Components and Hardware Needed: Qty

Cutterhead Guard .............................................. 1

Tools Needed: Qty

Hex Wrench 2.5mm .......................................... 1

To install the cutterhead guard:

1. Remove the set screw in the cutterhead guard

shaft (see Figure 22).

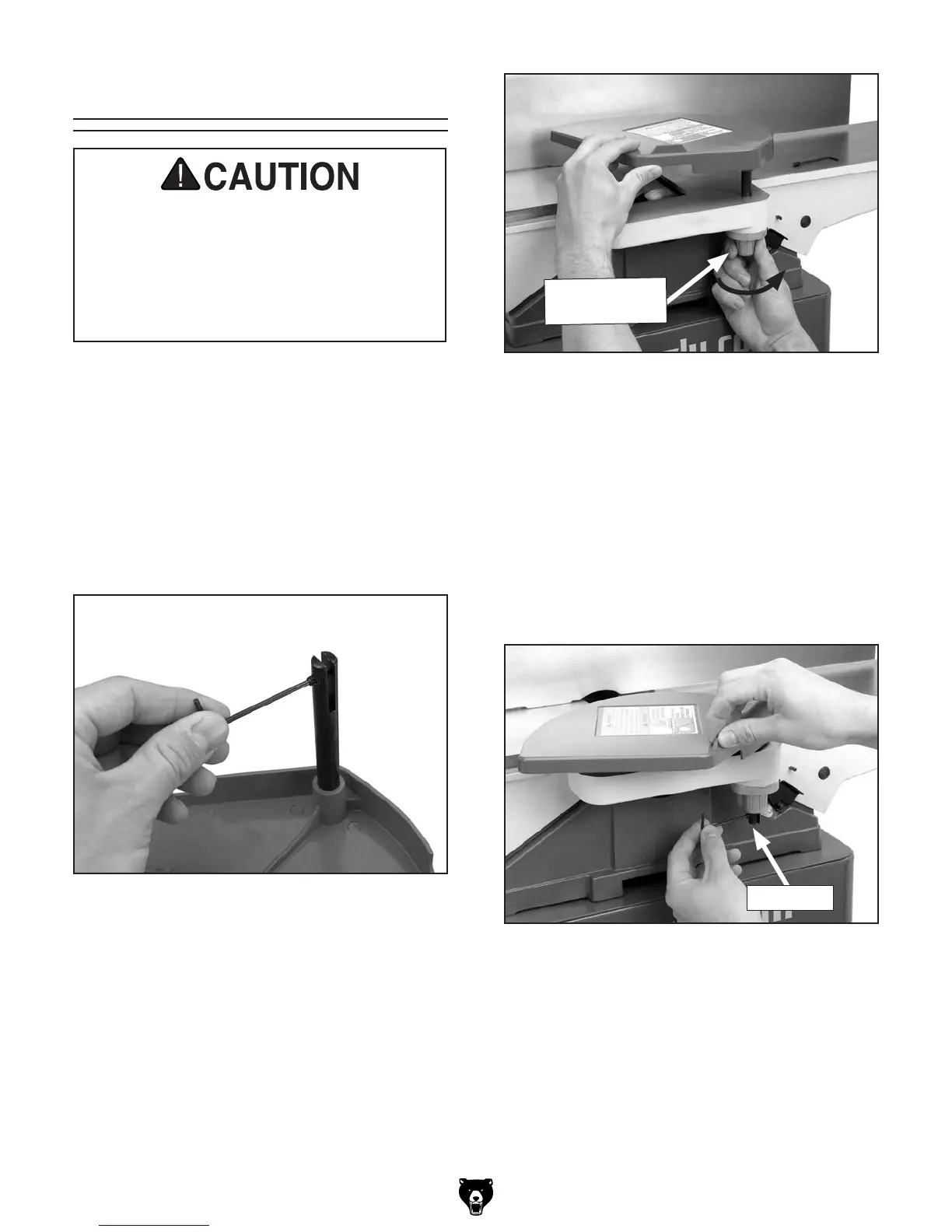

Figure 24. Re-installing set screw.

Set Screw

3. Test the guard by pulling it back and letting

go.

—The guard should snap back over the

cutterhead. If it does, re-insert the set

screw (see Figure 24).

—If the guard is slow to return across the

table, remove the shaft, and add a half turn

to the spring knob and test again. Repeat

this step as necessary.

Figure 23. Setting torsion spring knob.

2. Wind the torsion spring knob back counter-

clockwise a half turn, and slide the guard

shaft into the casting shown in Figure 23.

Make sure the slot on the cutterhead guard

shaft fits over the pin that sits inside the

spring knob barrel (hidden from view).

Cutterhead Guard

The cutterhead guard is a critical safety

feature on this machine. A torsion spring is

mounted on the cutterhead guard shaft to

help it return to its proper position over the

cutterhead after a cutting operation. This

torsion spring must have spring pressure

during guard installation to work properly.

Torsion Spring

Knob

Loading...

Loading...