-46-

Model G0452/P/Z (Mfg. Since 08/12)

G0452Z Replacing

Carbide Inserts

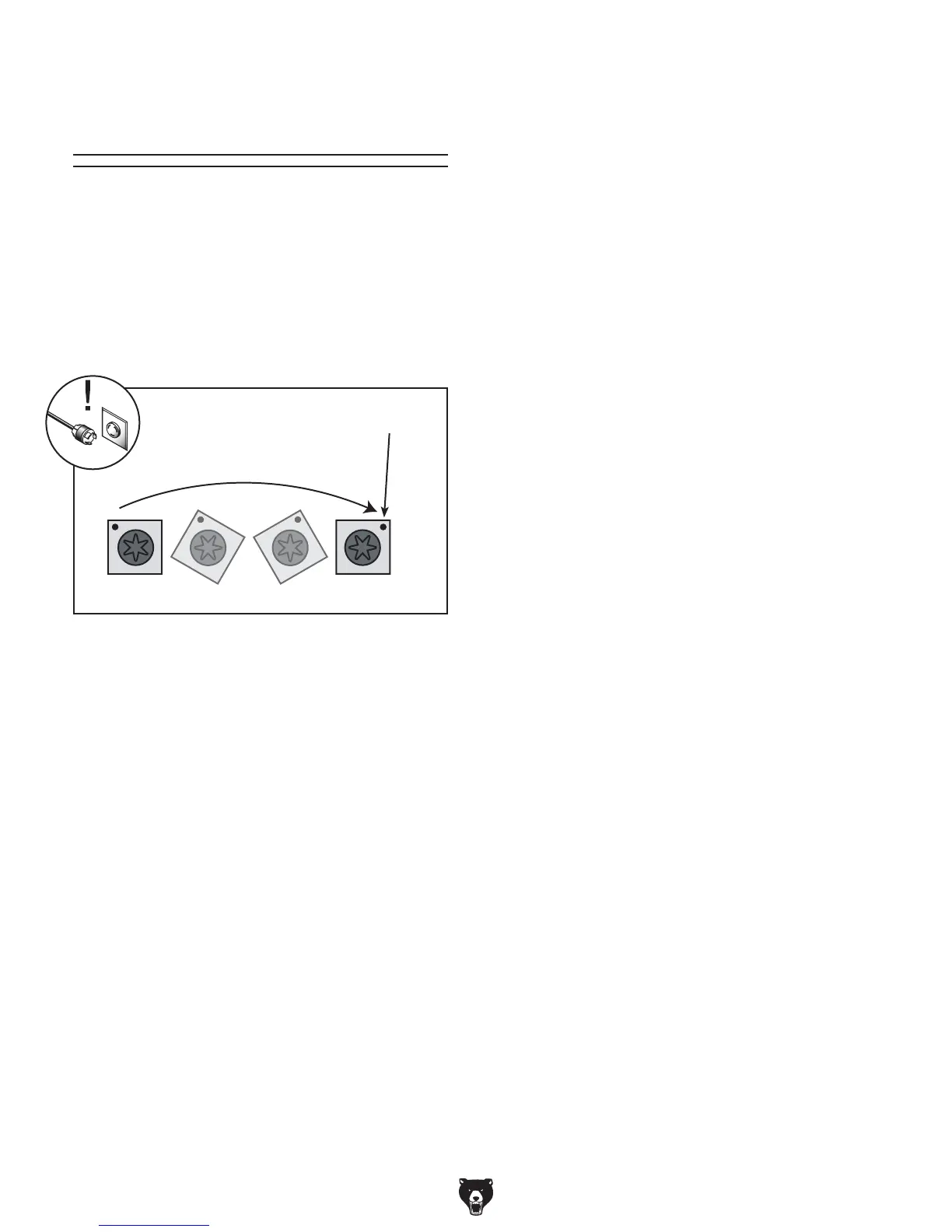

The Model G0452Z cutterhead is equipped with

32 indexable carbide inserts. Each insert can be

rotated to reveal any one of its four cutting edges.

Therefore, if one cutting edge becomes dull or

damaged, simply rotate it 90˚ to reveal a fresh

cutting edge (Figure 69).

Figure 69. Insert rotating sequence.

Reference Dot

In addition, each insert has a reference dot on

one corner. As the insert is rotated, the reference

dot location can be used as an indicator of which

edges are used and which are new. When the

reference dot revolves back around to its starting

position, the insert should be replaced.

Replacement carbide inserts should be included

with the cutterhead. If you need additional inserts,

call Grizzly Customer Service at (800) 523-4777

and order Model T21348, Replacement Indexable

Carbide Inserts for G0452Z, 10 pack.

Tools Needed: Qty

L-Wrench Torx with T20 Torx Driver .................. 1

To rotate or change a carbide insert:

1. DISCONNECT JOINTER FROM POWER!

2. Move the cutterhead guard out of the way, or

remove it.

3. Remove any sawdust from the head of the

carbide insert Torx screw.

4. Remove the Torx screw and carbide insert.

5. Clean all dust and dirt off of the insert and

the cutterhead pocket from which the insert

was removed, and replace the insert so a

fresh, sharp edge is facing outward. Make

sure the insert is seated in the pocket on the

cutterhead.

Note: Proper cleaning is critical to achieving

a smooth finish. Dirt or dust trapped between

the insert and cutterhead will slightly raise the

insert, and make noticeable marks on your

workpieces the next time you cut.

6. Lubricate the Torx screw threads with a

light machine oil, wipe the excess oil off the

threads, and torque the Torx screw to 48-50

inch/pounds.

Note: Excess oil may squeeze between the

insert and cutterhead or at the bottom of

the screw hole, causing hydrostatic lock and

preventing the screw from fully tightening,

thereby lifting the insert or screw slightly and

affecting workpiece finishes. Make sure to

carefully clean off any excess oil to prevent

this from happening.

Loading...

Loading...