Model G4000 (Mfg. Since 8/09)

-33-

Calculating Correct Spindle Speed

1. Use the table in Figure 43 to determine

the recommended cutting speed for the

workpiece material.

Note: Cutting speeds are expressed in SFM

(surface feet per minute) that the workpiece

moves against the cutter, which is different

from the spindle speed (RPM).

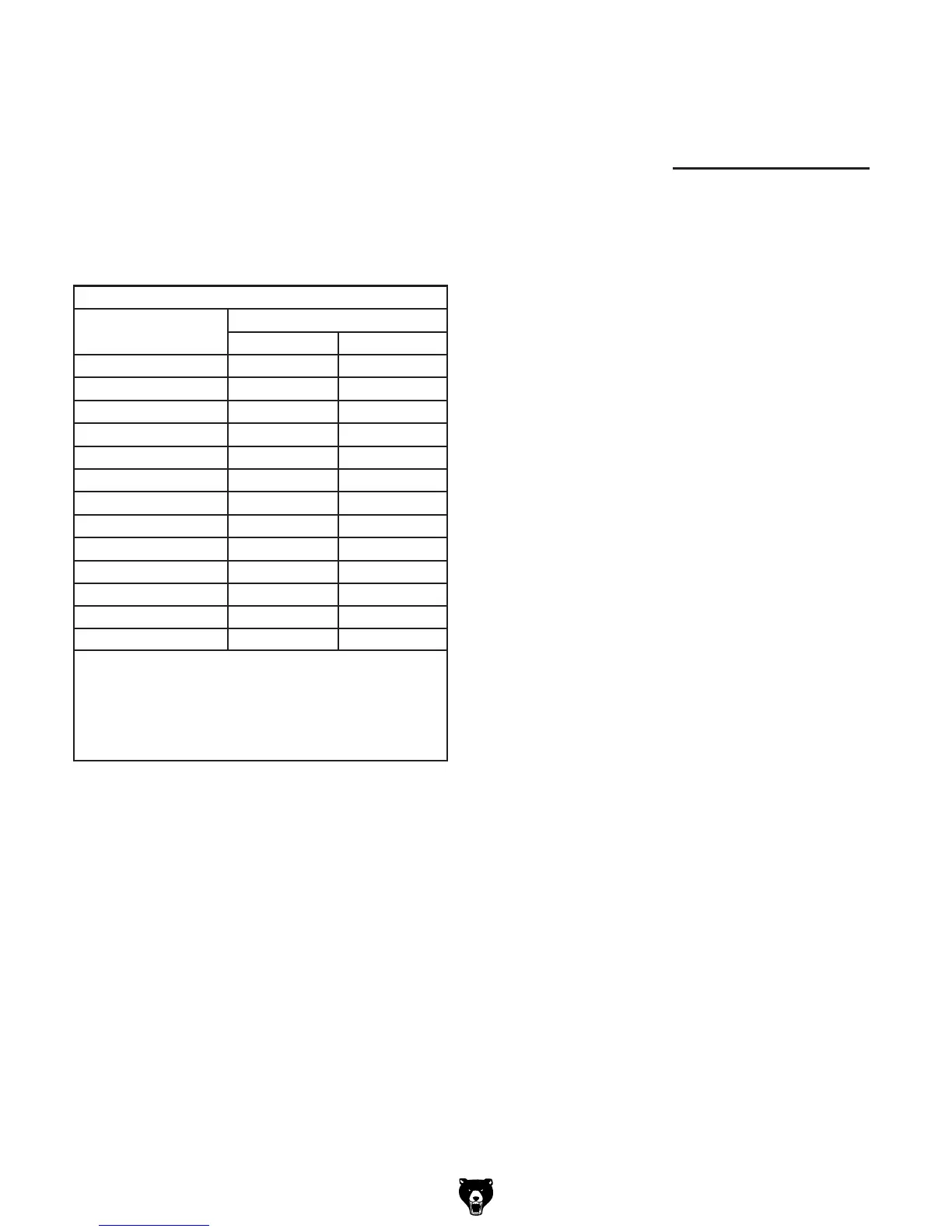

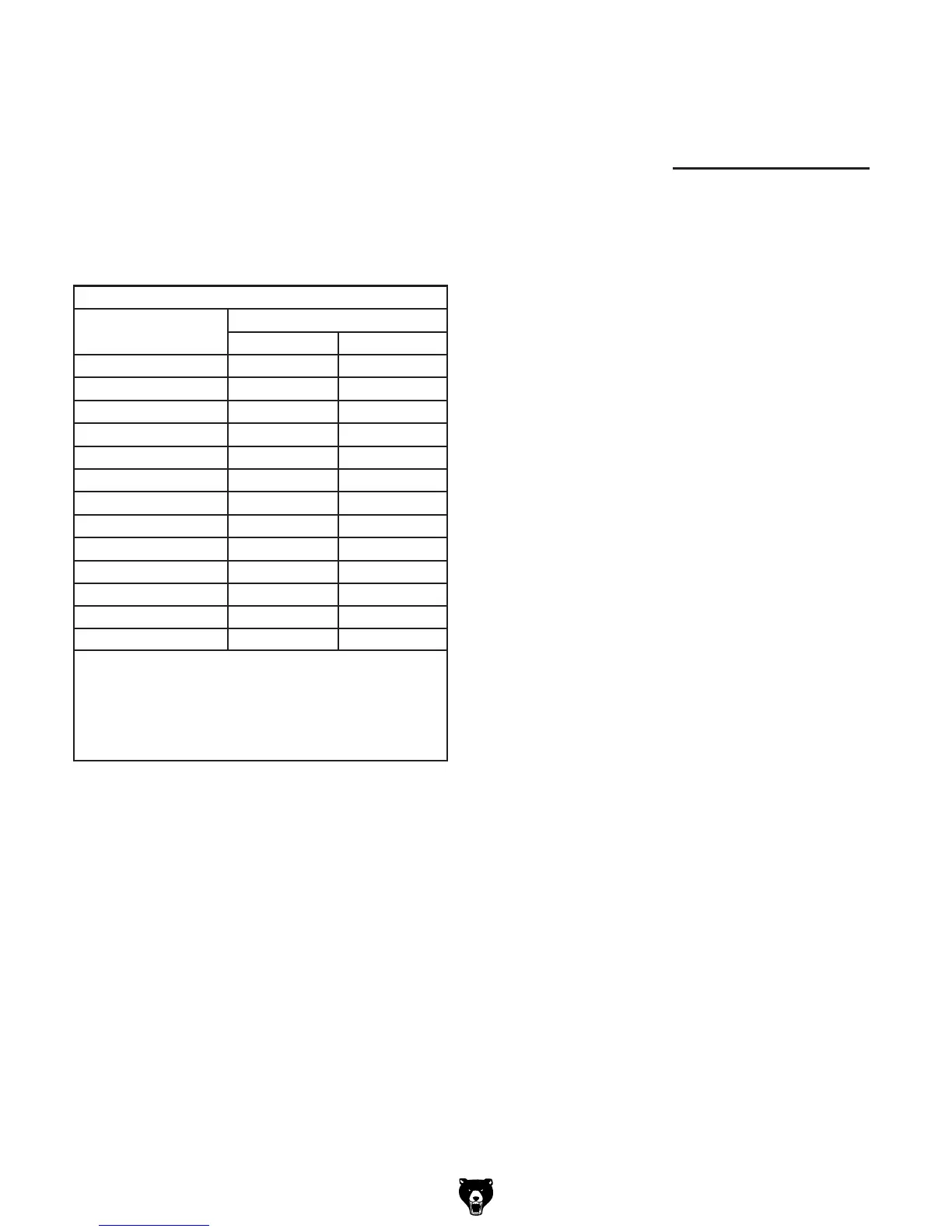

Recommended Cutting Speeds

Work Material

Magnesium

Aluminum

Brass & Bronze

Copper

Cast Iron (Soft)

Cast Iron (Hard)

Mild Steel

Cast Steel

Tool Steel

Alloy Steels (Hard)

Stainless Steel

Titanium

Hi Maganese Steel

Average Tool Speed (sfm)

Rough Cuts Finish Cuts

400

350

250

100

100

50

100

70

50

50

60

90

40

800

700

500

250

250

150

250

150

150

150

180

200

100

Note: These values are based on HSS cutting

tools. For carbide cutting tools, double the aver-

age speed. These values are a guideline only.

Refer to the MACHINERY’S HANDBOOK for

more detailed information.

Figure 43. Cutting speed table.

2. Determine the final diameter, in inches, for

the cut you intend to make.

Note: For this step, you will need to aver-

age out the diameters or work with the finish

diameter.

Example A:

You will finish cut

1

⁄2" diameter piece of

cast steel stock, using an HSS cutting

tool.

Step 1:

150 (SFM from chart) x 4 = 600

Step 2:

600 / .5" (Diameter of workpiece) = 1200

Result:

The correct spindle speed is 1200 RPM.

Example B:

You will rough turn a 1" diameter piece

of stainless steel, using a carbide cutting

tool.

Step 1:

60 (SFM from chart) x 2 (for carbide tool)

= 120

Step 2:

120 (Calculated SFM) x 4 = 480

Step 3:

480 / 1" (Diameter of workpiece) = 480

RPM

Result:

The correct spindle speed is 480 RPM.

3. Use the following formula to determine the

correct spindle speed (RPM) for your opera-

tion:

Diameter of Cut

Spindle Speed

=

Loading...

Loading...