Model G4000 (Mfg. Since 8/09)

-51-

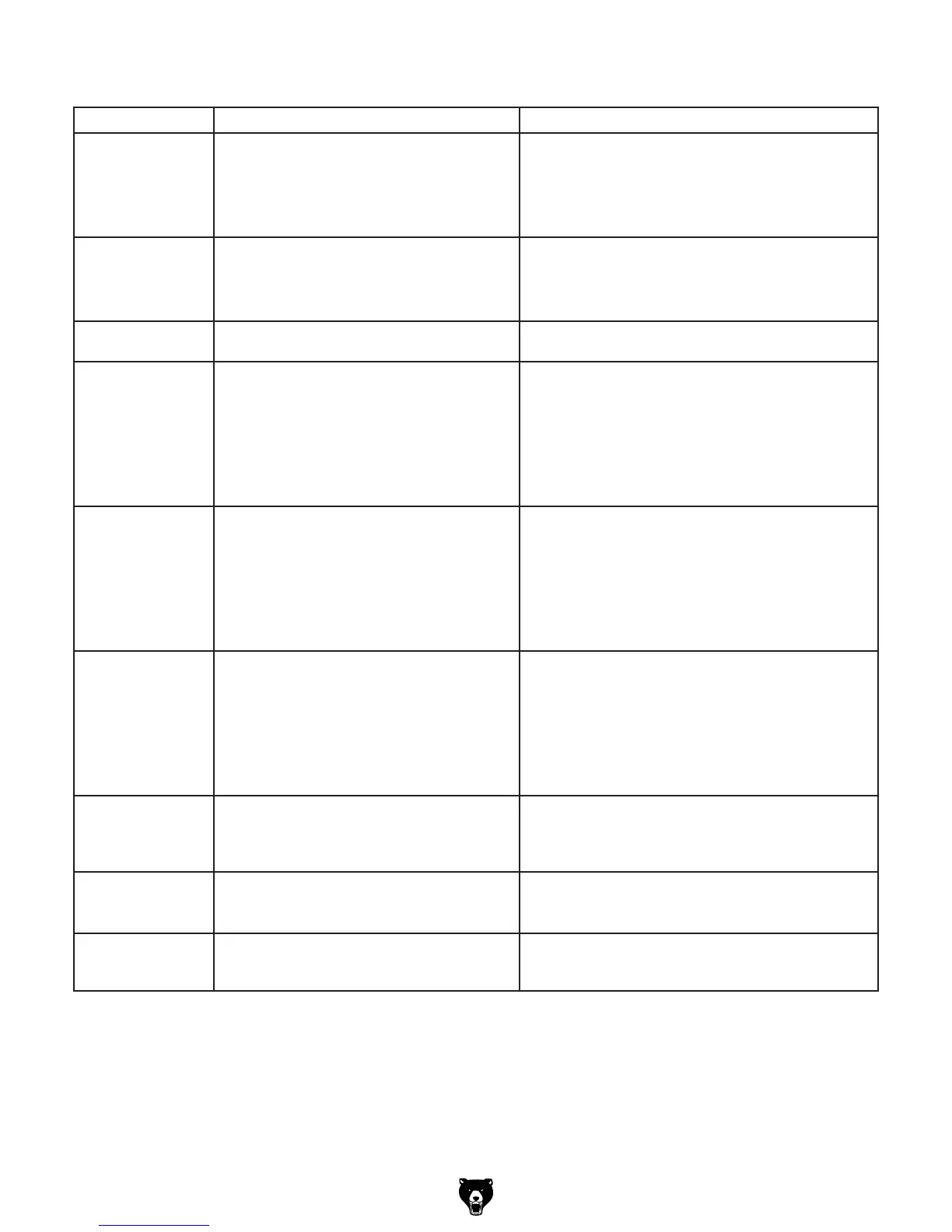

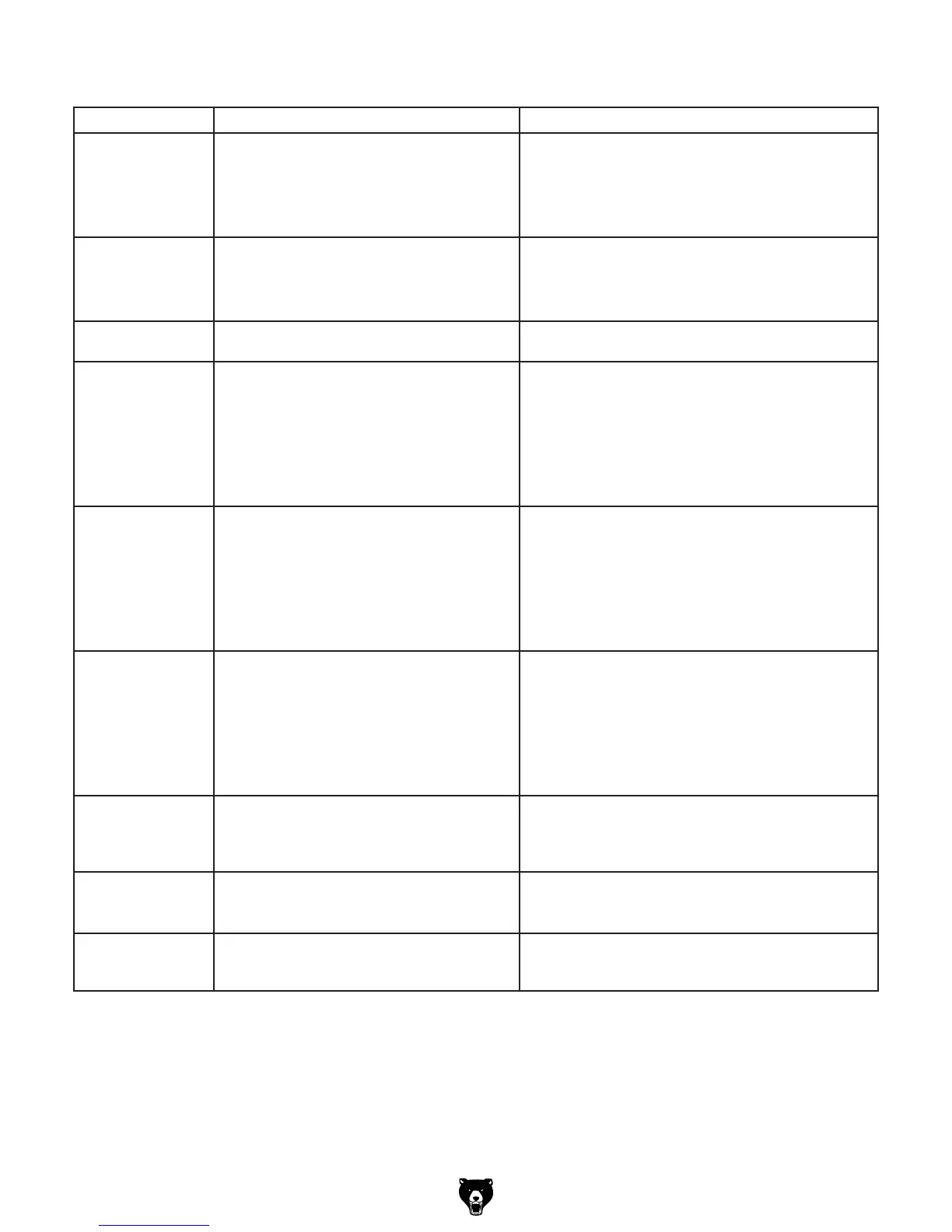

Operations

Symptom Possible Cause Possible Solution

Bad surface finish. 1. Incorrect spindle speed or feed rate.

2. Dull tool or poor tool selection.

3. Too much play in gibs.

4. Tool too high.

1. Adjust for proper spindle speed and feed rate

(Page 32).

2. Use sharp tools; use correct tool for the operation.

3. Adjust gibs (Page 52).

4. Lower tool position.

Cannot remove

tapered tool from

tailstock quill.

1. Quill not retracted all the way back into the

tailstock.

2. Debris/oil not removed from tapered mating

surfaces before inserting into quill.

1. Rotate the quill handwheel until the tapered tool is

forced out of quill.

2. Always make sure that tapered mating surfaces are

clean before inserting.

Gear(s) will not line

up and mesh.

1. Gear(s) not aligned. 1. Rotate spindle by hand until gear(s) falls into place.

Cutting tool

or machine

components vibrate

excessively during

cutting.

1. Tool holder not tight enough.

2. Cutting tool too far out from holder; lack of

support.

3. Too much play in gibs.

4. Cutting tool is dull.

5. Incorrect spindle speed or feed rate.

1. Check for debris, clean, and re-tighten.

2. Re-install cutting tool with no more than

1

⁄3 of total

length is sticking out of tool holder.

3. Adjust gibs (Page 52).

4. Sharpen/replace.

5. Adjust for proper spindle speed and feed rate

(Page 32).

Cross/compound

slide or carriage

feed has sloppy

operation.

1. Too much play in gibs.

2. Handwheel(s) loose.

3. Too much leadscrew backlash (cross slide

only).

4. Leadscrew mechanism worn or out of

adjustment.

1. Adjust gibs (Page 52).

2. Tighten handwheel fasteners.

3. Adjust leadscrew backlash (Page 53).

4. Tighten any loose fasteners on leadscrew

mechanisms; check for excessive wear/replace if

necessary.

Cross/compound

slide or carriage

feed hard to move.

1. Gibs are loaded up with chips/grime.

2. Gibs are too tight.

3. Leadscrew backlash setting too tight (cross

slide only).

4. Bedways are dirty/dry.

5. Gearing is at fault.

1. Remove gibs, clean ways, lubricate, and properly

adjust gibs (Page 52).

2. Adjust gibs (Page 52).

3. Properly adjust cross slide leadscrew backlash

(Page 53).

4. Clean and lubricate bedways.

5. Inspect/replace gearing.

Inaccurate turning

results from one

end of workpiece to

the other.

1. Tailstock not properly aligned with

headstock.

1. Properly align tailstock with headstock (Page 27).

Chuck jaws will

not move or do not

move easily.

1. Chips/debris lodged in jaws. 1. Remove jaws, clean and lubricate jaws, scroll-gear

threads, and chuck, then replace jaws.

Tailstock quill will

not feed out of

tailstock.

1. Quill lock is tightened down. 1. Turn quill lock counterclockwise to loosen.

Loading...

Loading...