37

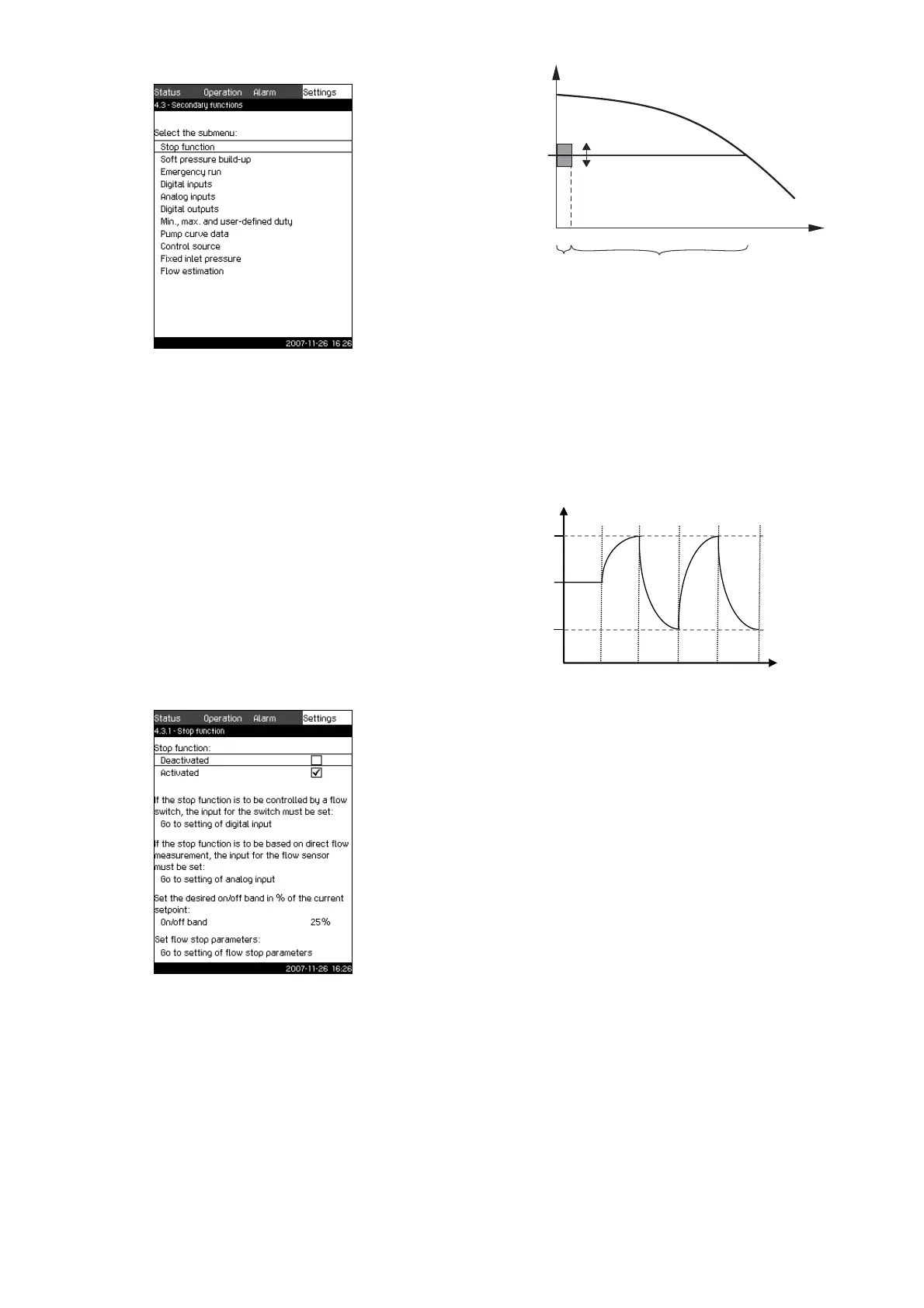

11.7.22 Secondary functions (4.3)

Fig. 58 Secondary functions

Description

Functions that are secondary in relation to the normal operation

of the system can be set in this display. Secondary functions are

functions that offer additional functionality.

The display makes it possible to open these specific displays:

• Stop function (4.3.1)

• Soft pressure build-up (4.3.3)

• Digital inputs (4.3.7)

• Analog inputs (4.3.8)

• Digital outputs (4.3.9)

• Emergency run (4.3.5)

• Min., max. and user-defined duty (4.3.14)

• Pump curve data (4.3.19)

• Flow estimation (4.3.23)

• Control source (4.3.20)

• Fixed inlet pressure (4.3.22).

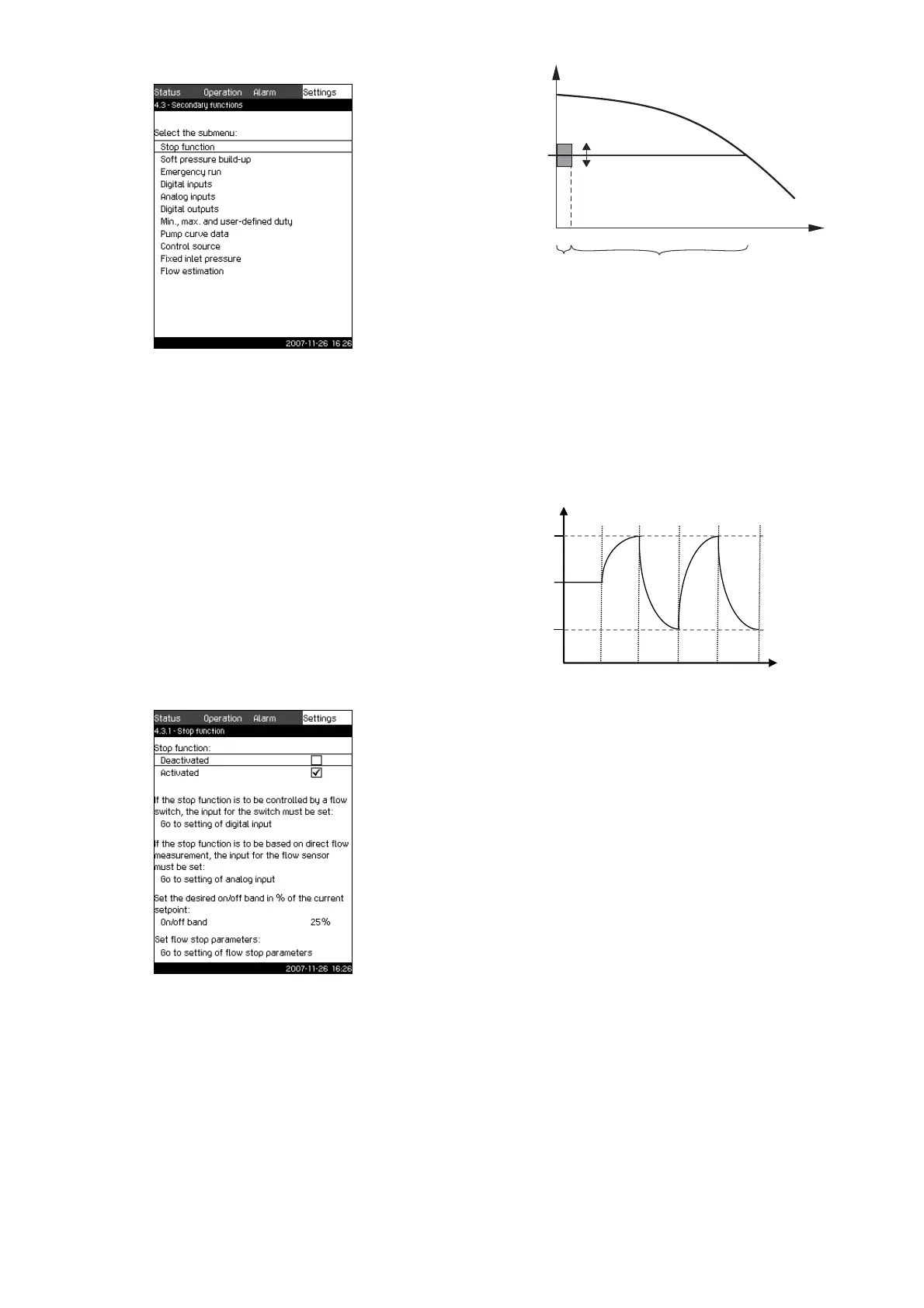

11.7.23 Stop function (4.3.1)

Fig. 59 Stop function

Description

This function is typically used in constant pressure applications

and makes it possible to stop the last pump if there is no or a very

small consumption. The purpose is to

• save energy

• prevent heating of shaft seal faces due to increased

mechanical friction as a result of reduced cooling by the

pumped liquid

• prevent heating of the pumped liquid.

The description of the stop function applies to all booster systems

with variable-speed pumps. Control MPC-S will have on/off

control of all pumps as described in section 8. Overview of control

variants.

Fig. 60 On/off band

When the stop function is activated, the operation is continuously

monitored to detect a low flow rate. When the CU 351 detects no

or a low flow rate (Q < Q

min

), it changes from constant-pressure

operation to on/off control of the last pump in operation.

Before stopping, the pump increases the pressure to a value

corresponding to H

set

+ 0.5 x on/off band. The pump is restarted

when the pressure is H

set

– 0.5 x on/off band. See fig. 61.

Fig. 61 On/off operation

The flow rate is estimated by the CU 351 when the pump is in the

stop period. As long as the flow rate is lower than Q

min

, the pump

will run on/off. If the flow rate is increased to above Q

min

, the

pump returns to normal operation, H

set

. H

set

is equal to the

current setpoint. See section 11.4.4 Setpoint (1.2.2).

Detection of low flow rate

Low flow rate can be detected by means of

• direct flow measurement with a flowmeter or flow switch

• estimation of flow rate by measurement of pressure and

speed.

If the booster system is not connected to a flowmeter or flow

switch, the stop function will use the estimating function.

If the detection of low flow rate is based on flow estimation, a

diaphragm tank of a certain size and with a certain precharge

pressure is required.

TM03 8969 4807TM03 2355 4607

TM03 1692 2705TM03 9292 4807

H

Q

H

set

Q

min

On/off band

On/off

control

Normal operation

Stop = H

set

+ 0.5 x on/off band

Start = H

set

– 0.5 x on/off band

Stop

Start

H [m]

Time [sec]

AB C B C

A: Normal operation

B: Pressure boosting

C: Stop

Loading...

Loading...