!

"

#

!

"

Planer-Thicknesser

A3-26 / A3-31 / A3-41

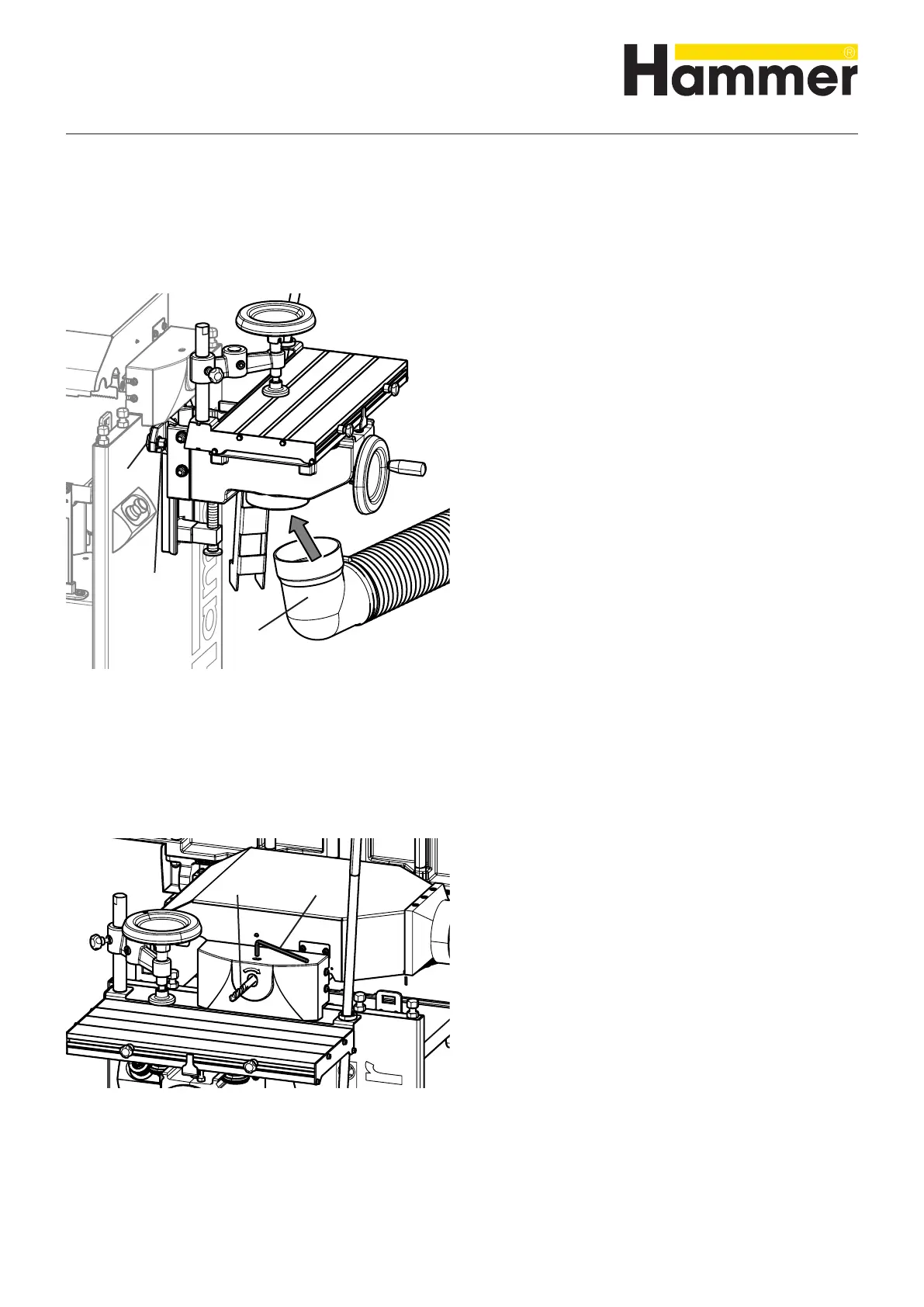

1. Prior to starting to work with the machine, switch it off

and secure it against being switched on again.

2. If necessary, mount the coupler unit (accessory). If

necessary, mount the 2-jaw drilling chuck (accessory).

(See assembly instructions „Drilling chuck and coupler

unit“)

3. Both planer tables must be tilted up and secured with

the fall locks

(Position „Thickness planing“)

4. Affix the drilling table:

• Depth adjustment in the hindmost position and

• Adjust the length in the middle position

5. Hook the mortising table into the seating bolt

6. Attach the drilling support with the nuts.

7. Connect the drilling support by means of the extractor

port to a suitable extraction system

See Chapter >7.3 Chip extraction<

! Seating bolt

" Nuts

# Vacuum connector

8.9 Retooling to the drilling unit

Fig. 8-13: Mounting the mortising support

8.9.1 Mounting the mortising support

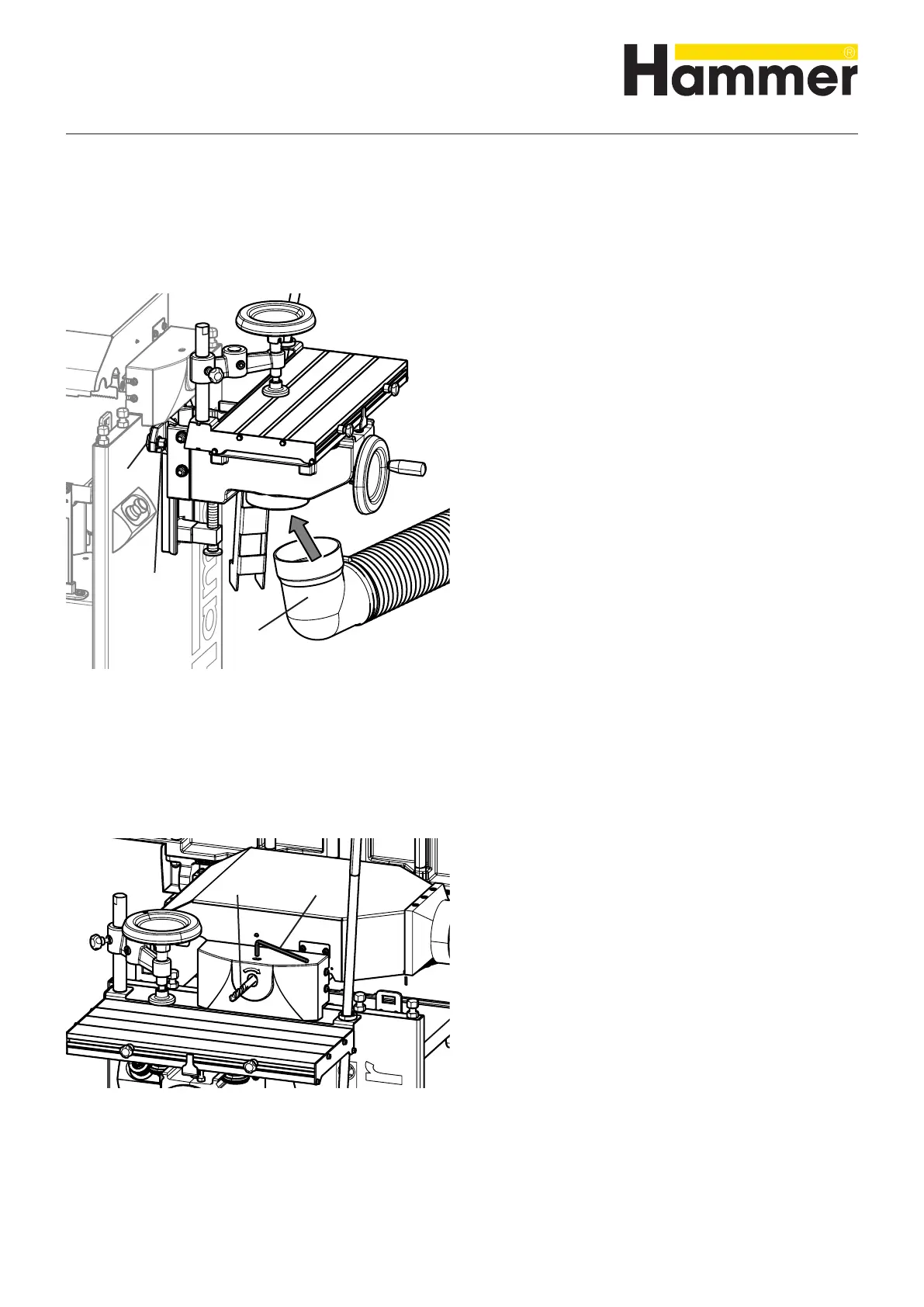

8.9.2 Clamp the drilling tool

1. Prior to starting to work with the machine, switch it off

and secure it against being switched on again.

2. Open the 2-jaw chuck with an 8 mm Allen key.

3. Clamp the authorised drilling tool along the entire

length of the chuck

See Chapter >9.6 Drilling<

4. Clamp the 2-jaw chuck with an 8 mm Allen key (mini-

mum torque 20 Nm).

! Allen key 8 mm

" Drilling tool

Fig. 8-14: Clamp the drilling tool

Making adjustments and preparations

Loading...

Loading...