Planer-Thicknesser

A3-26 / A3-31 / A3-41

9.4 Surface planing

Note: Surface planing evens irregular workpiece surfaces.

The workpieces are guided over the cutterblock and only their undersides are machined.

The direction of cutterblock rotation is opposite to the feed direction of the workpiece.

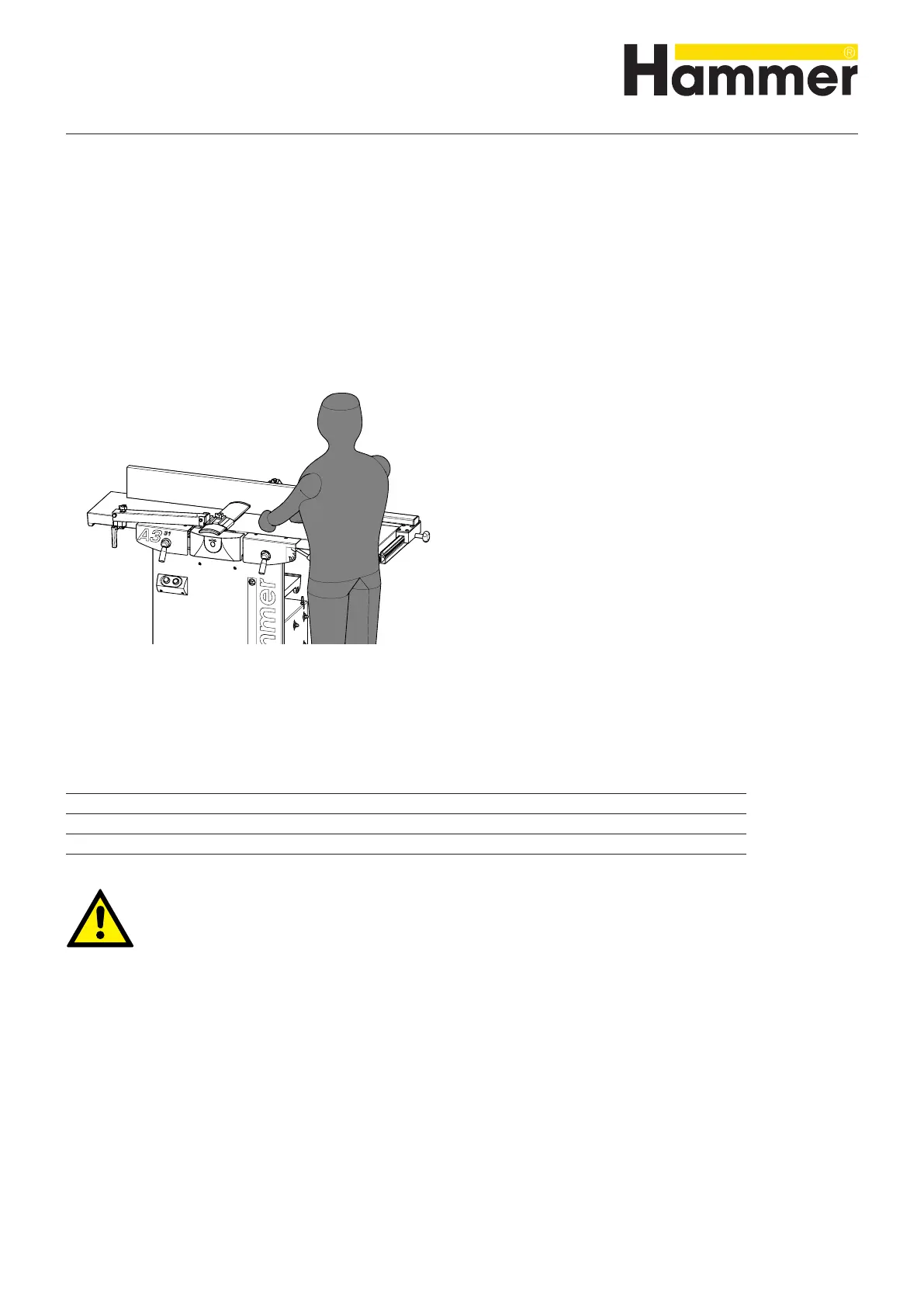

9.4.1 Working position

Fig. 9-3: Work place/work position

Take up the position as shown in the opposite picture

when working with the machine

The following working techniques are absolutely forbid-

den with the planer unit:

• Down-cut planing (direction of cutterblock rotation is

the same as feed direction)

• Insertion cuts (the workpiece is not worked over its

entire length)

• Planing workpieces that are very warped

• Rabbet planing at the end of the cutterblock

9.4.3 Authorised and prohibited work techniques

Only the following working techniques are permitted

with the planer unit:

• Planing the wide side of a workpiece

• Jointing the narrow side of a workpiece

• Bevelling the narrow side of a workpiece

• Bevelling the edges of a workpiece

9.4.2 Workpiece dimensions

Length under 250 mm: only work with special devices (e.g.: wooden pushing stick)

over 1500 mm: only work with table extensions or with a second person

Width max. 260 mm / 310 mm / 410 mm (depending on the equipment)

Thickness min. 10 mm

Attention! Risk of injury!

If a workpiece is smaller than 10 mm, it may split if the depth of cut is too large (4 mm).

The finished planed workpiece must not be thinner than 6 mm!

Operation

Loading...

Loading...