48

Planer-Thicknesser

A3-26 / A3-31 / A3-41

9.5 Thickness planing

Note: Workpieces that already have a planed surface can be made thinner by being thicknessed. The

workpieces are guided through the planer. The workpiece lies with its planed surface on the thicknessing

table, and only the upper side is machined.

Only the following working technique is permitted on the

thicknessing unit:

• A maximum of 2 workpieces can be thickness-planed

simultaneously.

Attention! Risk of material damage!

When working on 2 workpieces simultaneously, their thickness may not differ by more than 1 mm.

It is absolutely forbidden to perform the following

working technique on the thicknessing unit:

• Thicknessing several workpieces of varying

thicknesses

9.5.1 Workpiece dimensions

9.4.8 Tapering/beveling small workpieces

Width max. 206 mm / 306 mm / 406 mm (depending on the equipment)

Thickness min. 4 mm

max. 250 mm

See Chapter:

>9.4.7 Bevelling/Tapering<

• When bevelling or tapering small, narrow workpieces,

always use a special power feeder.

• The power feeder is mounted onto the planer fence.

• Set the bridge guard all the way down and let the

protective bridge rest against the power feeder.

9.5.2 Authorised and prohibited work techniques

Attention! Risk of injury!

When bevelling or tapering small, narrow workpieces, always use a special power feeder.

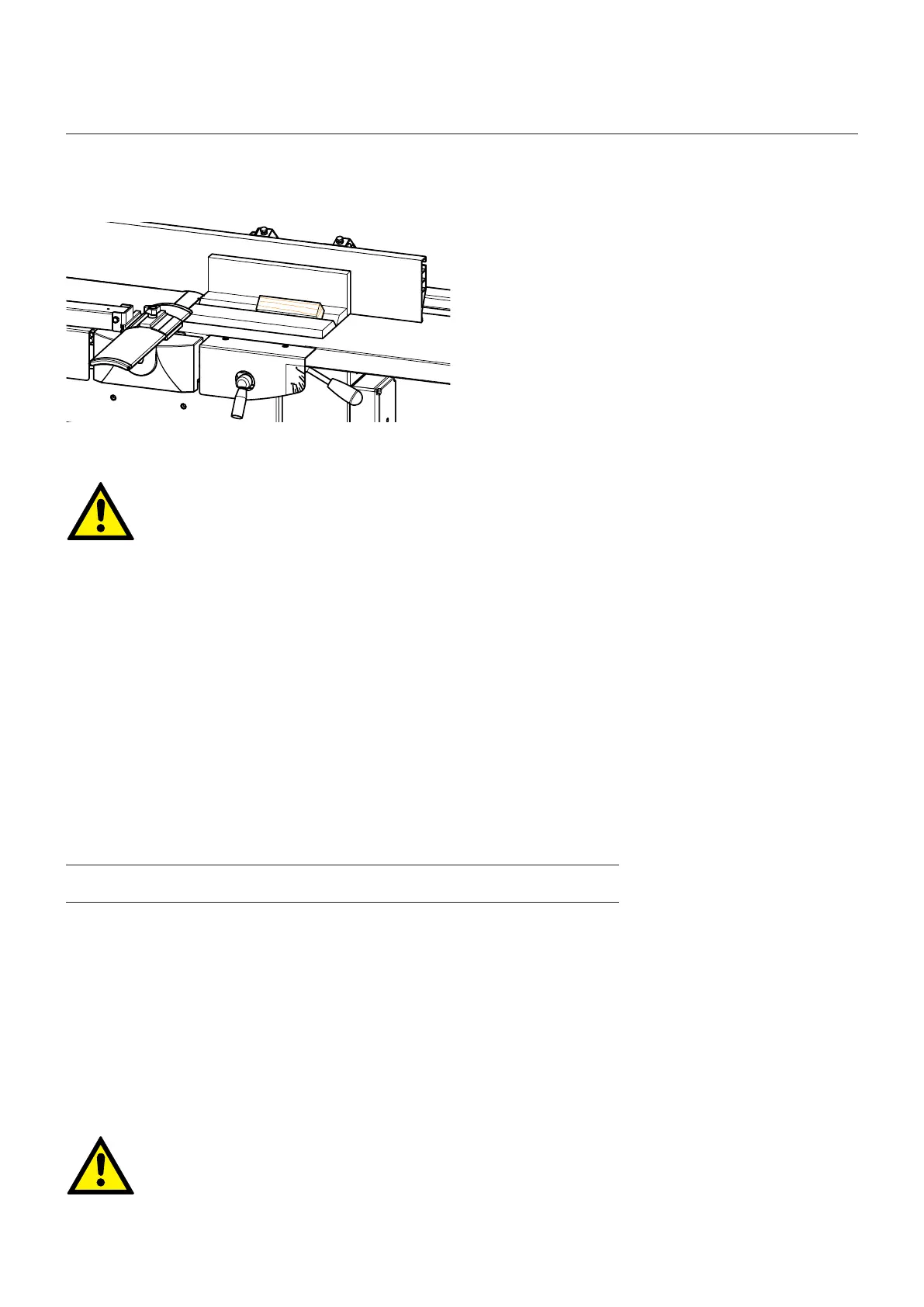

Fig. 9-16: Jig

Operation

Loading...

Loading...