"

!

#

#

#

"

!

Planer-Thicknesser

A3-26 / A3-31 / A3-41

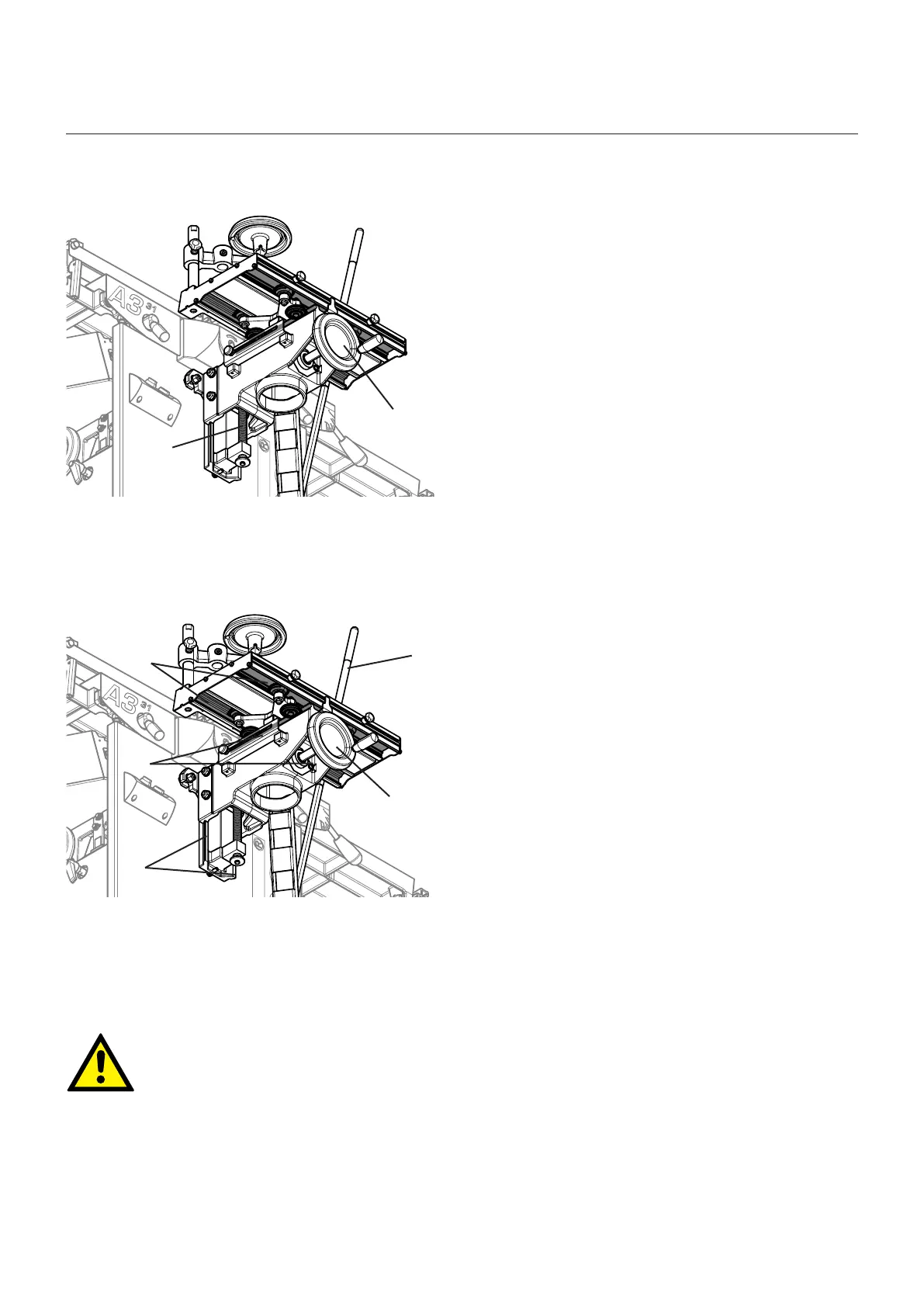

10.3.8 Greasing the height spindle (drilling support)

1. Before beginning any maintenance work on the

machine, switch it off and secure it against acciden-

tally being switched on again.

2. Wipe away old grease residues and remove dust

from the spindle.

3. Lubricate the spindle with regular machine grease.

4. Use the system handwheel to move the drilling table

all the way up and down.

! Spindle

" System handwheel

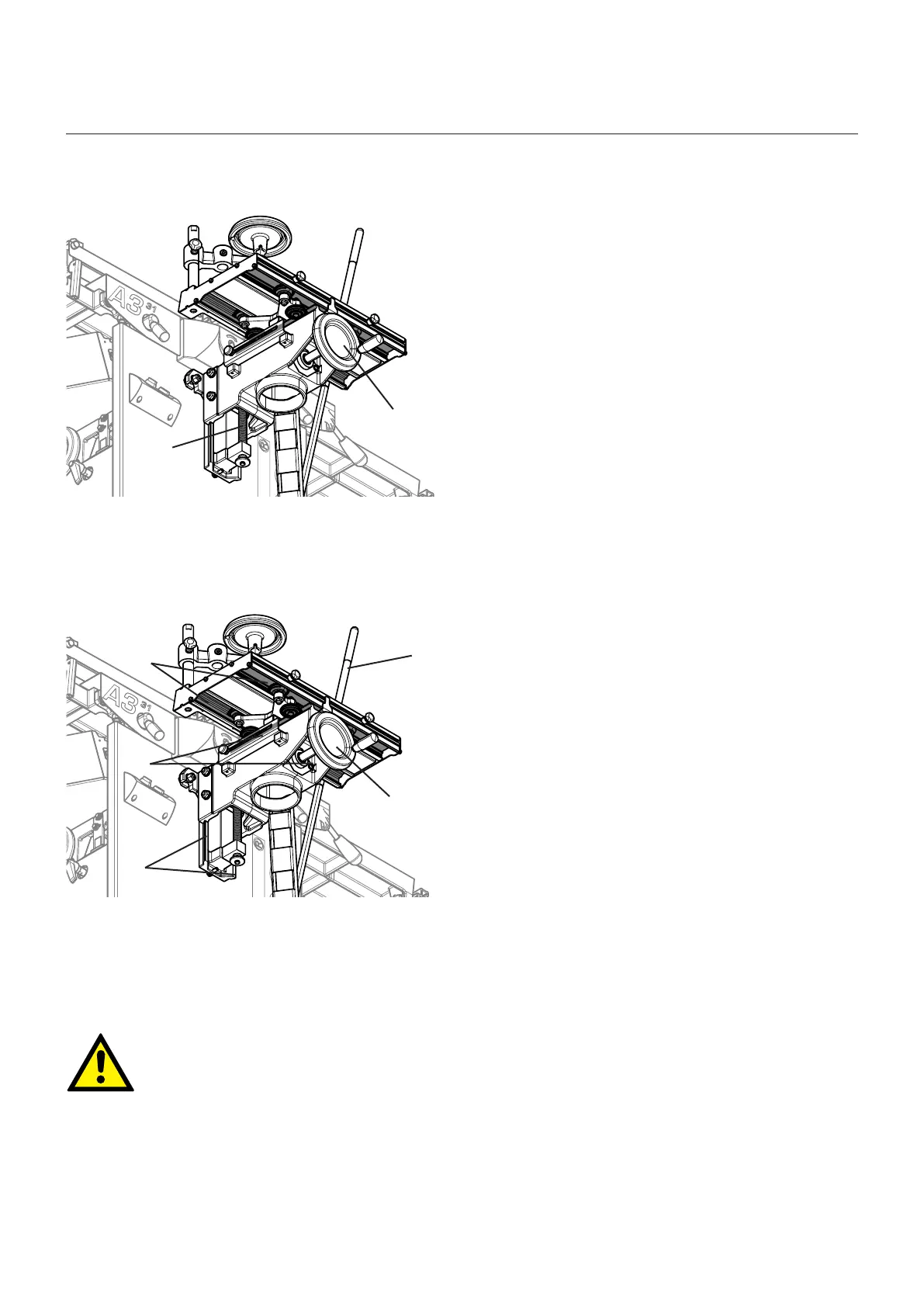

10.3.9 Cleaning the guides (drilling support)

1. Before beginning any maintenance work on the

machine, switch it off and secure it against acciden-

tally being switched on again.

2. Use the system handwheel to move the drilling table

into the uppermost position

3. Use the one-hand lever to move the mortising table

into the front-most position on the left side

4. Clean the guides with a soft cloth.

on the reverse side, too

5. Use the one-hand lever to move the mortising table

into the hindmost position on the right side

6. Clean the guides with a soft cloth

! Single-hand lever

" System handwheel

# Guides

Attention! Do not grease or oil the guides!

Fig. 10-11: Cleaning the guides

Fig. 10-10: Lubricating the height spindle

Service

Loading...

Loading...