CHAPTER 1 - INSTALLATION

MACHINE INSTALLATION REQUIREMENTS

T-42, T-51, and T-65 lathes require a substantial foundation. Do not locate the machine near equip

-

ment that causes vibration. Poor surface finishes or damage to the control may result from vibration

transmitted to the machine.

FOUNDATION REQUIREMENTS

Refer to Figure 1.1, 1.2, or 1.3 to locate the feet in the machine base. Use the dimensions to size the

machine footprint and locate the concrete pads.

The soil under the pads or floor for the machine must be compacted to a safe bearing capacity of 4

tons per square foot [0.38 MPa].

The pads must be level with each other within ±.13 inch [±3.3 mm] or the floor must be level within

±.13 inch in 5 feet [±3.3 mm in 1524 mm] and be constructed of 3000 psi [207 bars] concrete or better.

Avoid placing the machine over floor expansion joints.

RECOMMENDED 6 inch [152 mm] thick concrete floor as large as the machine footprint.

The machine footprint is the overall dimensions, length and width, of the

machine.

ACCEPTABLE Concrete pads 14 x 14 x 6 inches [356 x 356 x 152 mm] centered under

each of the machine feet.

MINIMUM 4 inch [102 mm] thick concrete floor as large as the machine footprint or

concrete pads 14 x 14 x 4 inches [356 x 356 x 102 mm] centered under

each of the machine feet.

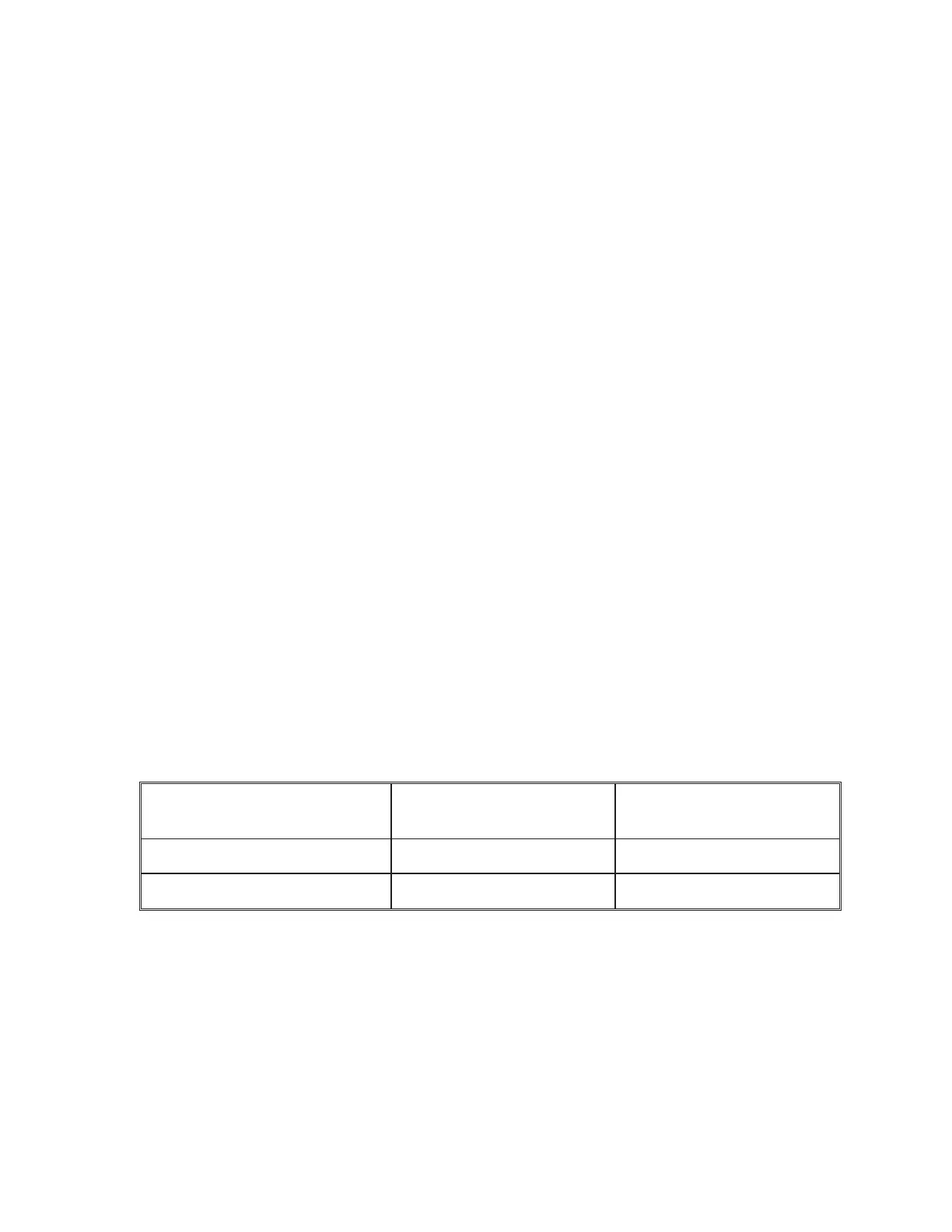

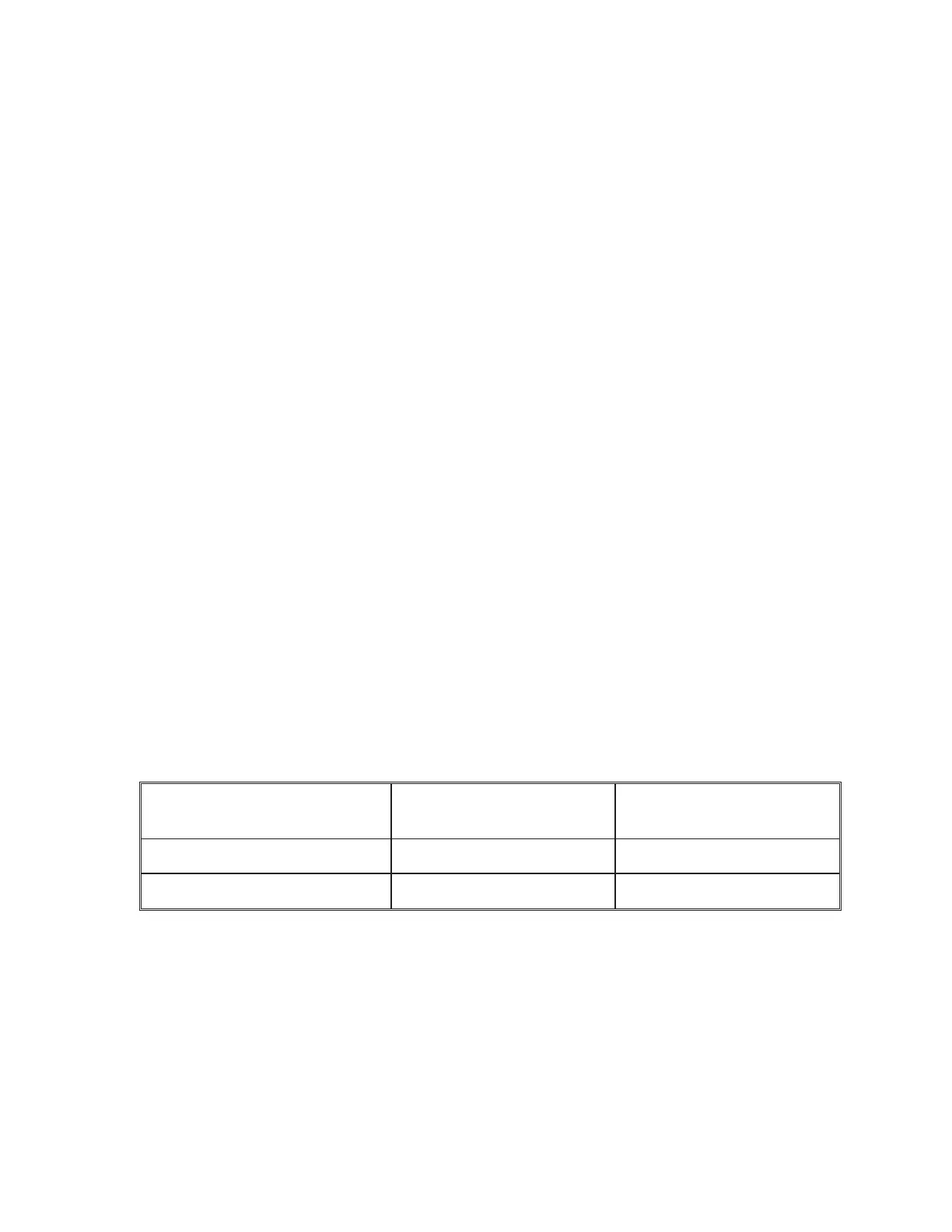

APPROXIMATE WEIGHT

- NOTE -

The machine weight and shipping weight will vary, depending on the configuration

of the machine.

Machine Model

Machine Weight

lb [Kg]

Shipping Weight

lb [Kg]

T-42 Lathe 12,600 [5,715] 13,200 [5,988]

T-51 and T-65 Lathes 17,900 [8,165] 18,800 [8,528]

Refer to the machine weight tag mounted on the power case door.

M-507C 1-1

Loading...

Loading...