31

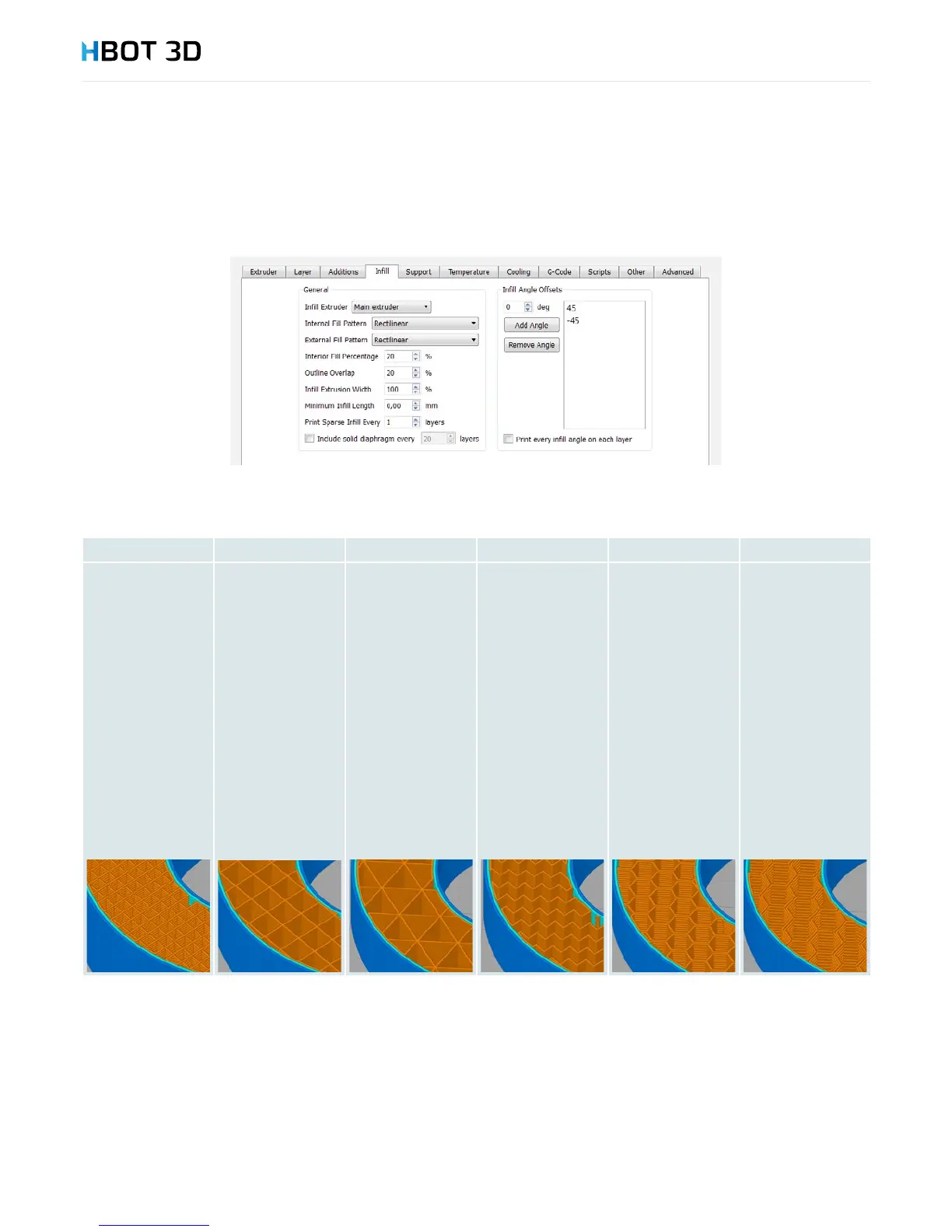

Inll tab

This sections enables you to modify interior ll parameters, mainly inll density and inll pattern (Interior Fill Percentage and Internal Fill

Pattern).

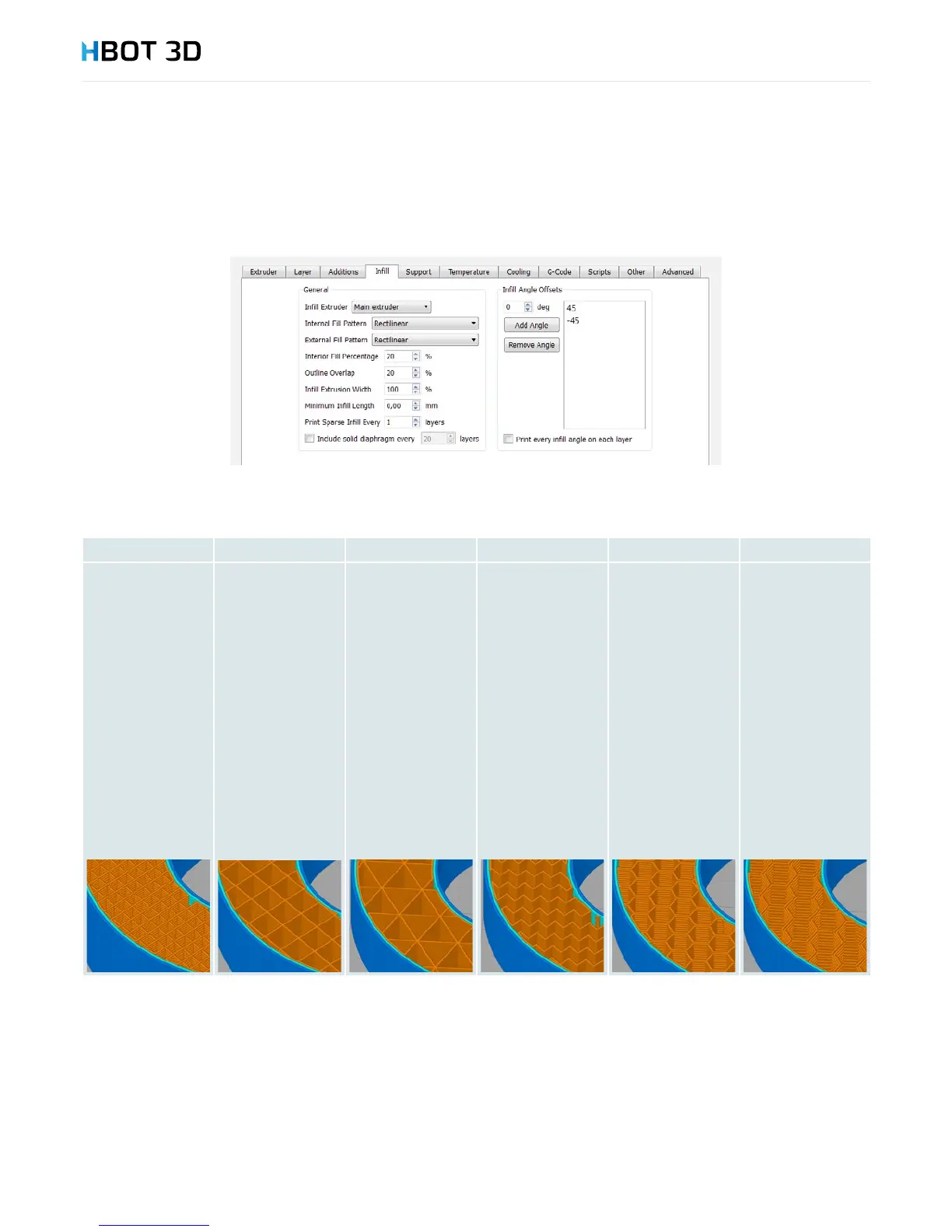

You have 6 different inll patterns to choose from:

Rectilinear Grid Triangular Wiggle Fast Honeycomb Full Honeycomb

Inll pattern

with the lowest

strength for low

inll percentage,

highest strength

for 80-100% inll

percentage. It is the

only inll pattern

that could be set to

100%. Inll paths do

not intersect within

the same layer.

Inll pattern with

a higher strength

for lower inll

percentages.

Maximum setting

which if congured

will not cause print

problems is 80%,

but the optimum

one is 20-40%. This

shape differs from

the Rectilinear

one in that the

paths intersect one

another within the

same layer, causing

better adhesion of

the entire inll.

The same inll

pattern as Grid, but

inll paths intersect

with one another

at 60-degrees. This

is the most stiff

and strongest inll

pattern for low inll

percentages. Like

in the case of the

Grid inll pattern,

maximum inll

percentage is 80%

and the optimum

one is 20-40%.

Polyline-shaped

inll pattern.

Simplied

honeycomb. A

structure with

similar properties

to the Triangular

one, also stiff but

less strong than the

full honeycomb.

Maximum inll

percentage is 80%,

and the optimum

one is 20-40%.

Full honeycomb.

Characteristic for

double inll path,

making the structure

very strong at low

inll percentages.

Support tab

Support Inll Percentage – inll density of support structures. The higher the inll density, the more accurately the support structures

are lled, but the print time and material consumption signicantly increase. Optimum value of this parameter is 20%.

Dense Support Layers – the number of support layers with the dense inll percentage where paths of your model are directly laid

down at. The more number of solid layers, the better support for curved and rounded surface. If support structures need to be quickly

removed, you may set the number of dense support layers to 0, but the quality of supported surface will be much worse.

Dense Inll Percentage – inll percentage of the dense support layers. The less density, the easier support removal but the lower

quality of the supported model surface.

Loading...

Loading...