46 CDM 3201 Order No. BA 92-12-3321A Issue 19.09.08

5.8 Checking the Quality of the Weld

You can check the quality of the weld by means of a visual inspection and a bending

test.

See also actual standards in the appendix “Arc stud welding of

metallic materials“, in section irregularities and corrective

actions

5.8.1 Visual Inspection

A visual inspection must be carried out with each welding element.

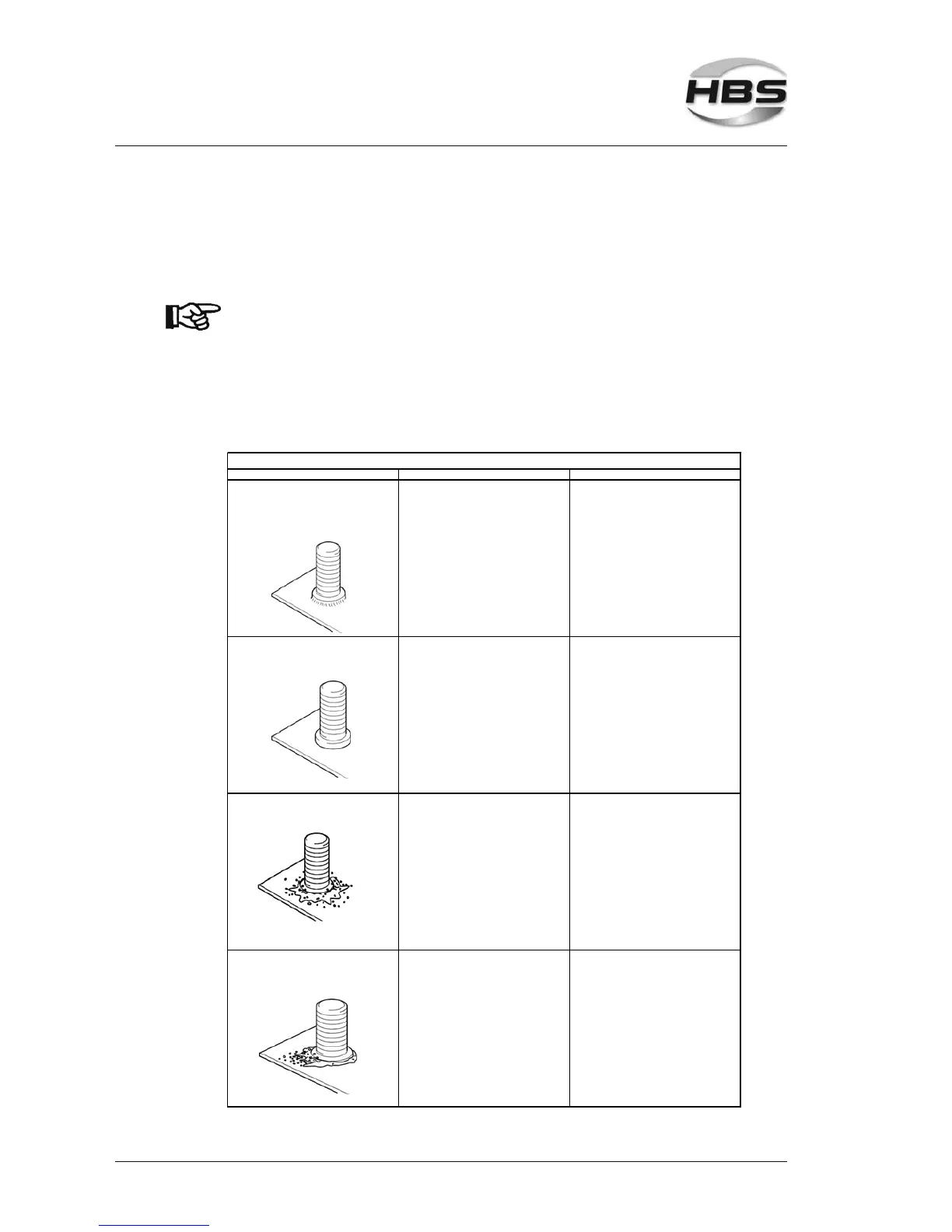

Condition Possible cause Corrective actions

Good welded joint

Low spatters around the weld

without outer flaws

The weld pool forms a collar around

the flange of about 1 - 1,5 mm

- Correct parameters - None

Cold weld pool

Gap between flange and workpiece

- Heat input too low

- Plunging speed too low

- No sufficient backing of workpiece

- Increase charging voltage

- Adjust plunging speed correctly

- Provide sufficient backing

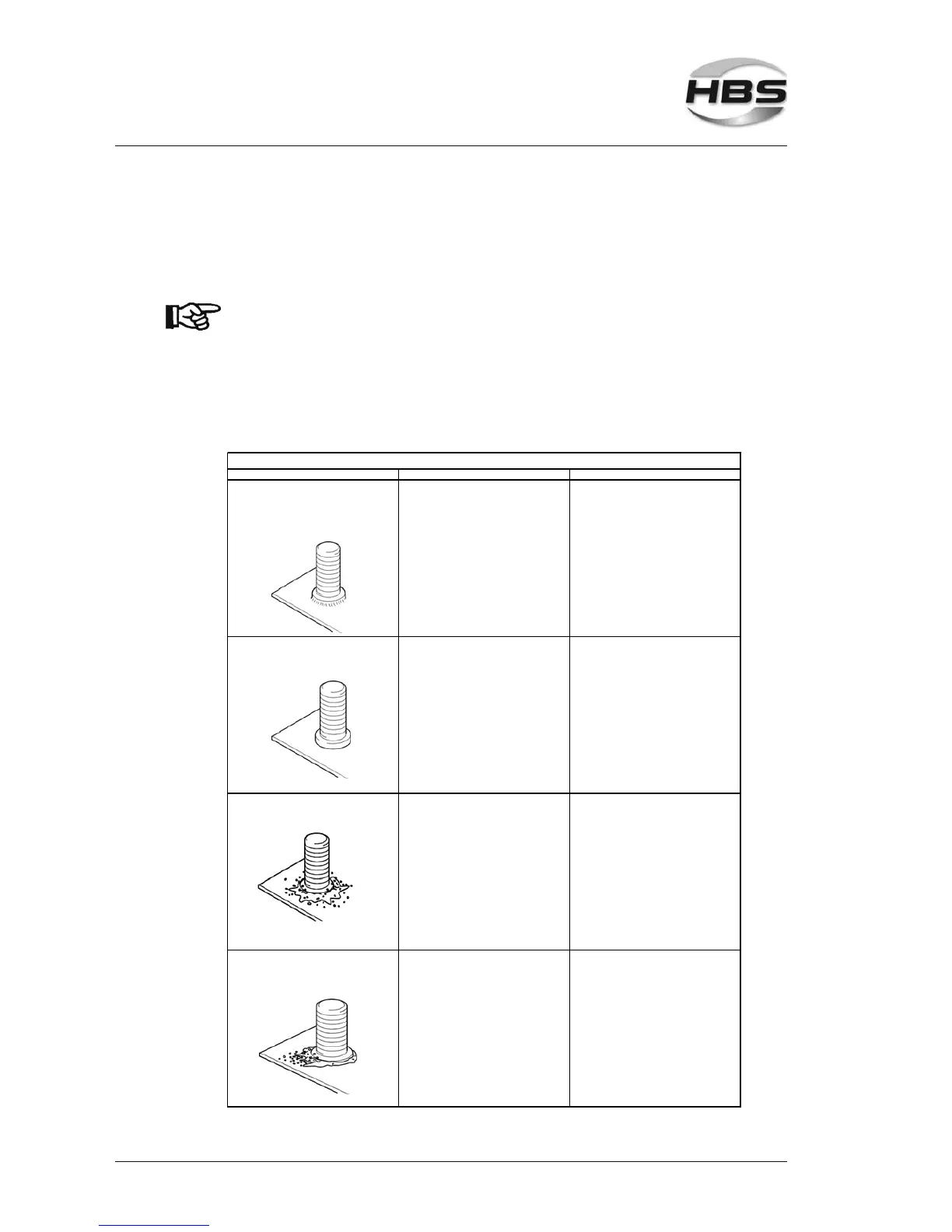

Hot weld pool

Many spatters around the weld

- Heat input too high

- Plunging speed too low

- Reduce charging voltage

- Increase plunging speed

One-sided weld pool

One-sided spatter collar

Weld pool came out on one side

- Arc blow effect

- Unsymmetric ground connection

- Welding gun put at an angle

- Take care for s ymmetrical ground

connection

- Put welding gun vertically to the workpiece

Visual Inspection

5 Stud Welding Procedure

5.8 Checking the Quality of the Weld

Loading...

Loading...