50 CDM 3201 Order No. BA 92-12-3321A Issue 19.09.08

5.9 Malfunctions and Corrective Actions

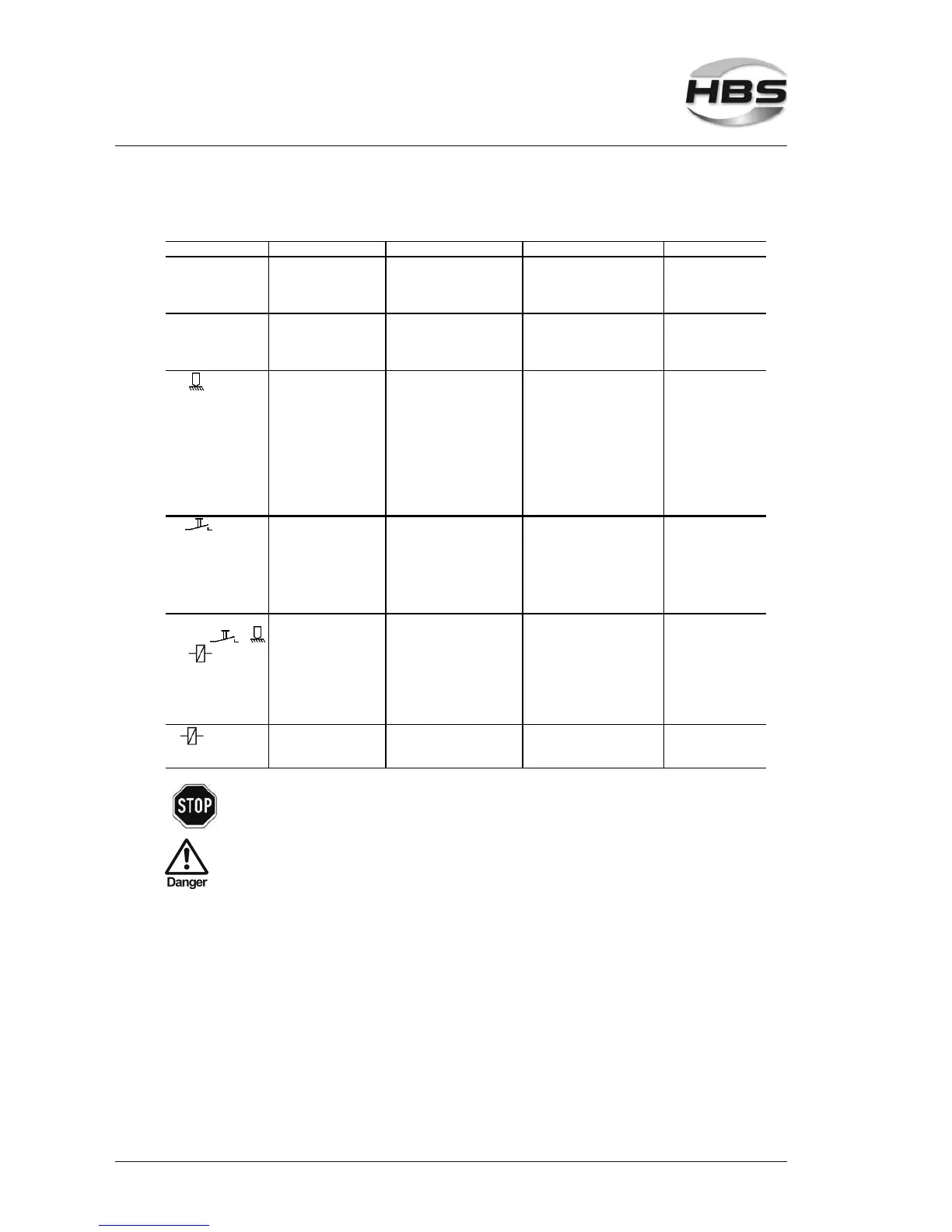

Malfunction Possible cause Fault finding Corrective action Carried out by

Li ght sig nal of prim ar y

switch does not light

Primary outlet defective Check primary outlet *) Replace primary outlet *) Qualified personnel

Mains cable broken Check mains cable *) Replace mains cable *) Qualified personnel

No LED display at the

front

Fuse F4 10 AT defec tive Check mains fuse Replace mains fuse F4 on the

fr on t pl ate of the power unit

Instructed personnel

Leads interrupted Check leads *) Replace leads *) Qualified personnel

No display No ground connection Check ground connection on

work piece

Tighten ground connection

properly

Instructed personnel

Gun not connected Check welding gun connection Connect welding gun properly Instructed personnel

Transition resistance

(between stud and

workpiece) too high

Check m ateri al s urface C lean or gr in d mate ri al sur face Instr uc ted perso nnel

Ground cable broken Check ground cable *) Replace ground cable *) Qualified personnel

Welding gun cable broken Check welding gun cable *) Replace welding gun cable *) Qualified personnel

No display Defective c onnecting line

of welding gun

Check functi on of connecting

line *)

Replace connecting line *) Qualified personnel

Welding gun trigger button

defective

Check control cable for

electrical flow with triggered

start button *)

Replace welding gun trigger

button *)

Qualified personnel

Control cable broken Check control cable for

electrical flow*)

Replace control cable *) Qualified personnel

Gun does not lift, in

spite of ,

and

No lift adjusted Check settings of welding gun Modify set parameters Instructed personnel

Short circuit of solenoid

cir cu it of the gun

Check resistance value at

control cable (18

to 2 2

)

between Pin 1 an d Pi n 2 *)

Replace control cable, control

line, solenoid *)

Qualified personnel

Solenoid defective

Check solenoid (18

to

22

) *)

Replace solenoid *) Qualified personnel

No display Solenoid circuit interrupted Check resistance value at

control cable (18

Ω

to 2 2

)

between Pin 1 an d Pi n 2 *)

Replace solenoid or control line

*)

Qualified personnel

Actions marked with *) must only be carried out by qualified

electricians!

If none of the actions is successful, please contact our service

department.

5 Stud Welding Procedure

5.9 Malfunctions and Corrective Actions

Loading...

Loading...