CDM 3201 Order No. BA 92-12-3321A Issue 19.09.08 35

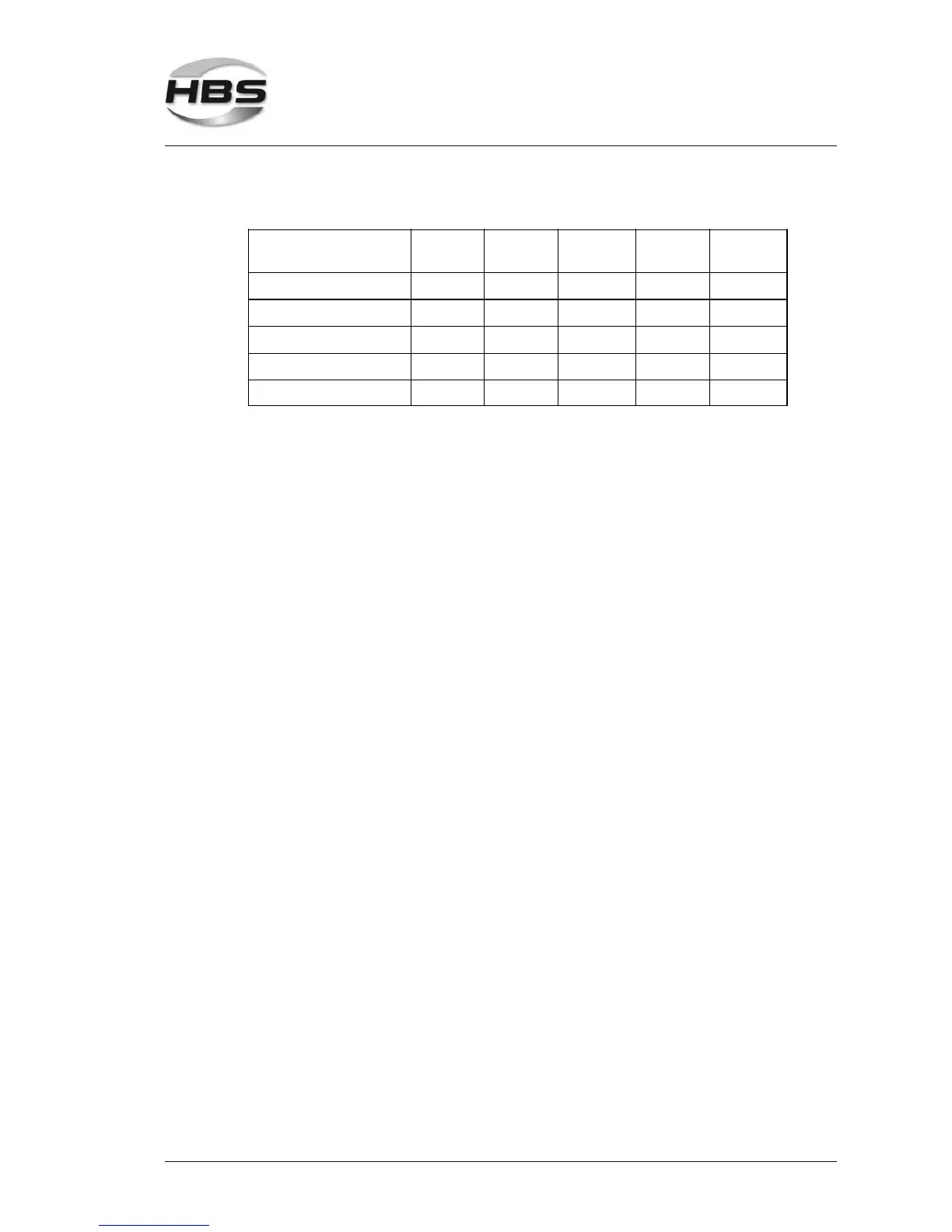

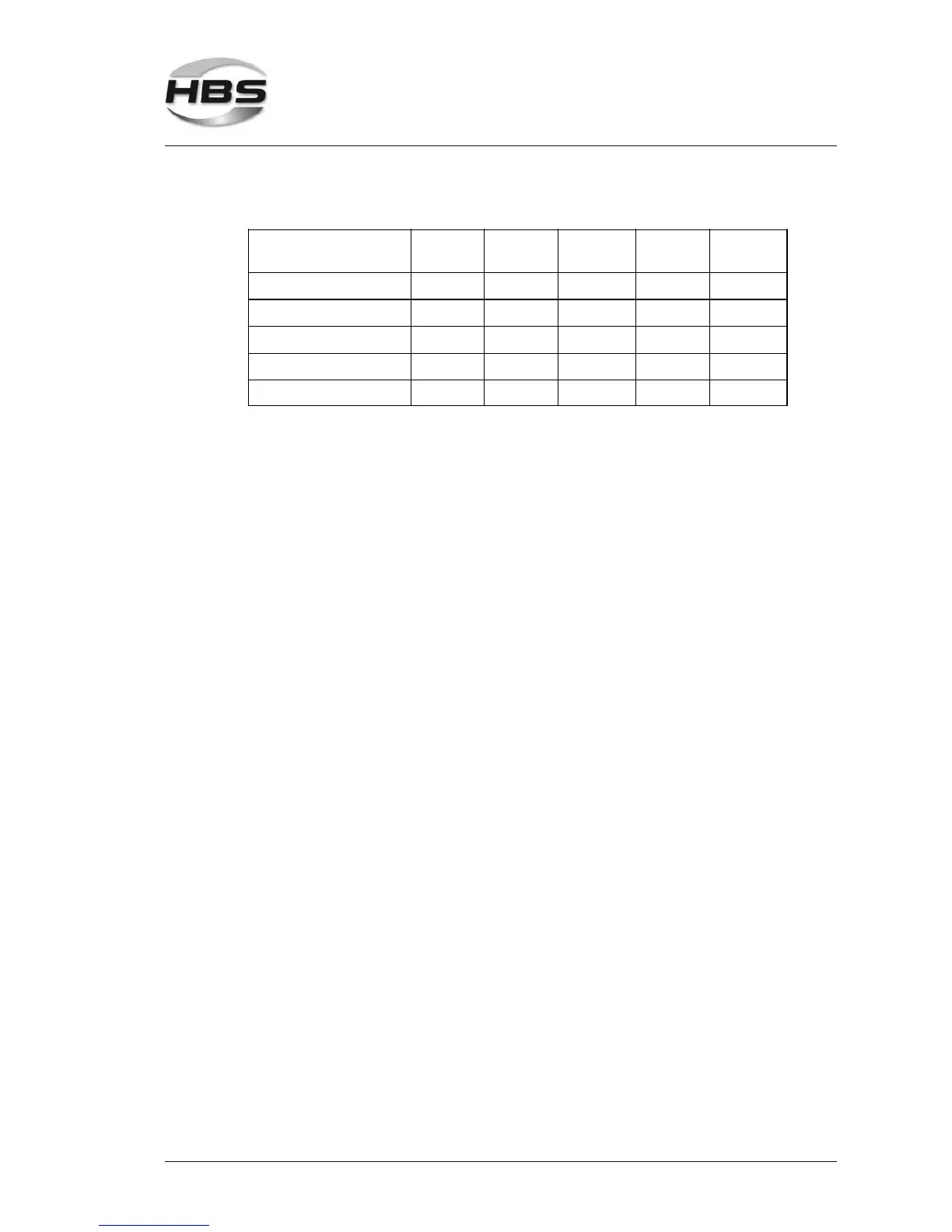

Setting the library mode

Material

Diameter

M3

Diameter

M4

Diameter

M5

Diameter

M6

Diameter

M8

S235 80 V 100 V 130 V 170 V 220 V

S235 + Zn 100 V 130 V 190 V 220 V

1)

1.4301 60 V 90 V 120 V 160 V 220 V

AlMg3 70 V 100 V 130 V 160 V

1) 2)

CuZn37 60 V 70 V 120 V 180 V

1)

Preset values (guidelines) of library mode

1)

Only possible with use of a stronger power source

2)

Check by trial welds

5.6.4 Setting the Controls

Process sequence control (PAF)

To be able to assess the welding procedure during welding, the present values are used

to calculate the PAF value (PAF = Process Analysis Factor). A calculation of the PAF

is carried out by a special algorithm which is stored in the micro-controller. This system

of process monitoring does not require any special welding guns and/or additional

measurement cables.

During welding the reference part, the micro-controller determines the PAF reference

value. This is the average value of eight subsequent welding processes.

During standard operation, the current PAF value is compared with the reference PAF

value. If the value out of the set tolerance range, the system indicates and displays a

deviation via the LED´s. You can lock the system after indication of a deviation.

You can manually enter a PAF value. This value must be determined by 8 reference

welds. In this way, the PAF value can be stored for different program sequences. It is

possible to store an individual PAF value for each stud/lot dimension and to carry out

a process monitoring.

5 Stud Welding Procedure

5.6 Switching on the Power Unit

Loading...

Loading...