IT 1002 Order No BA 93-66-1206 Issue 03.11.08 33

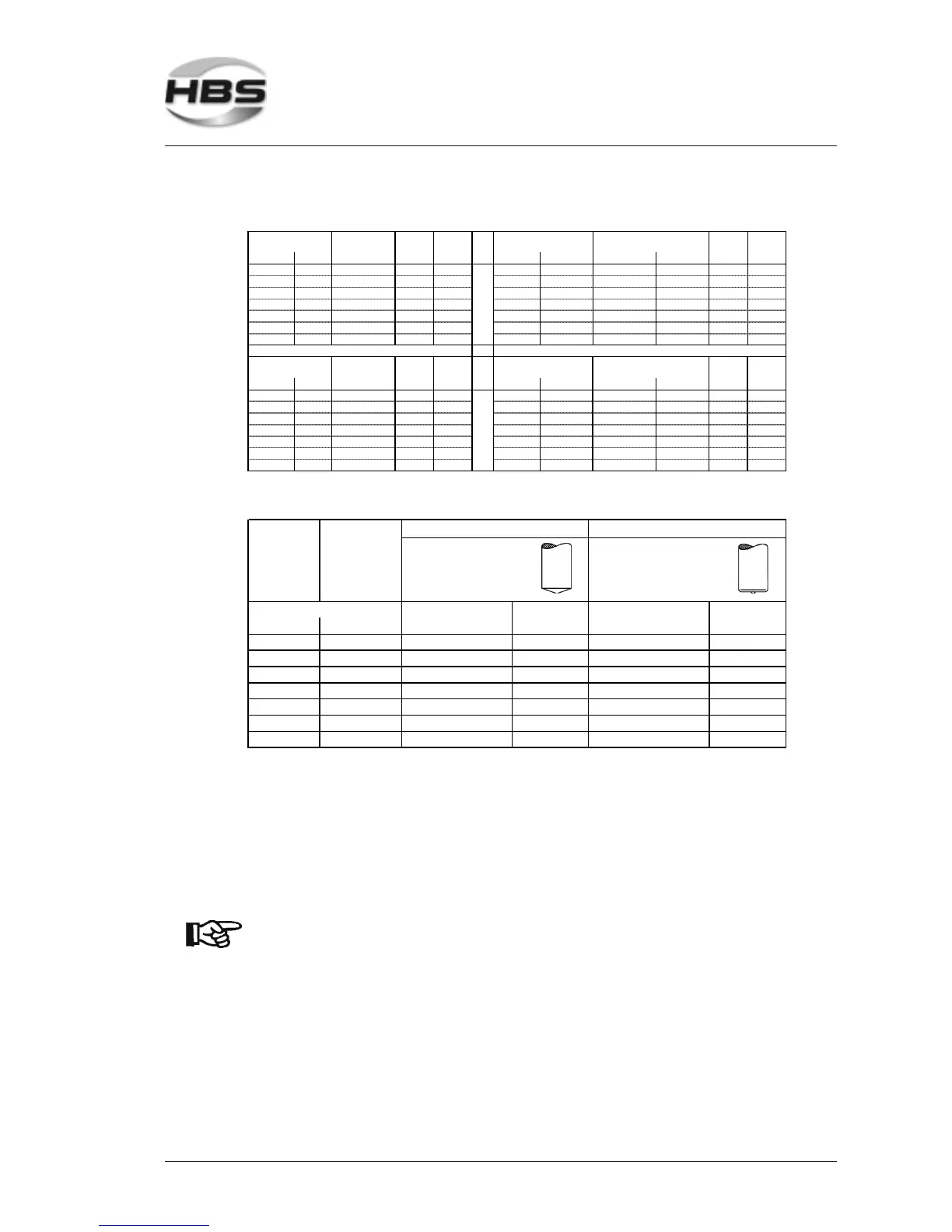

Setting of power unit *)

eff. Diameter

(mm/inches)

Welding

current A

Welding

time (ms)

Welding

current A

Welding

time (ms)

(metric) (imperial) (metric) (imperial) (metric/mm) (imperial)

M3 1/8" not standardized - - 3 #4 or 12 gage 3 #4 or 12 gage 240 60

M4 5/32" not standardized - - 4 #8 4 #8 320 80

M5 3/16" not standardized - - 5 #10 or 3/16" 5 #10 or 3/16" 400 100

M6 1/4" 4,7/0.19 380 100 6 1/4" 6 1/4" 480 120

M8 5/16" 6,2/0.24 500 130 8 5/16" 8 5/16" 640 160

M10 3/8" 7,9/0.31 640 160 10 7/16" 10 7/16" 800 200

M12 1/2" 9,5/0.37 760 190 12 1/2" 12 1/2" 960 240

eff. Diameter

(mm/inches)

Welding

current A

Welding

time (ms)

Welding

current A

Welding

time (ms)

(metric) (imperial) (metric) (imperial) (metric/mm) (imperial)

M3 1/8" not standardized - - M3 1/8" 4 #8 400 60

M4 5/32" not standardized - - M4 5/32" 5 #10 or 3/16" 500 80

M5 3/16" not standardized - - M5 3/16" 6 1/4" 600 100

M6 1/4" 5,4/0.21 432 108 M6 1/4" 7 0.28" 700 110

M8 5/16" 7,2/0.28 576 144 M8 5/16" 9 0.35" 900 140

M10 3/8" 9/0.35 720 180 M10 3/8" 11 0.43" 1000 190

M12 1/2" 10,9/0.43 872 218 M12 1/2" not standardized - - -

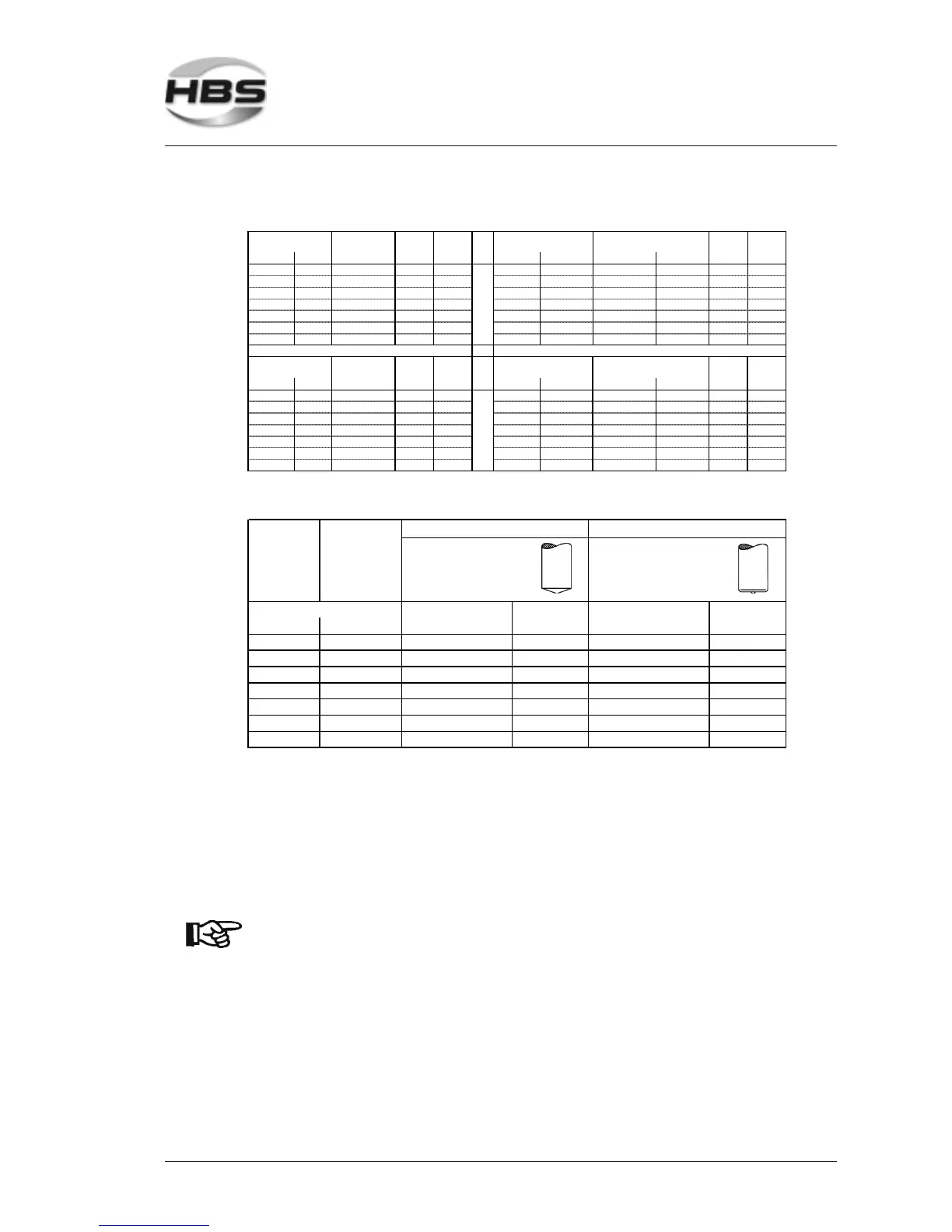

Designation

RD

Designation

UD / Pins

eff. Diameter

Designation

DD

(MD)

Designation

FD

eff. Diameter

Setting of welding gun

Plunging depth Lift Plunging depth Lift

(metric/mm) (imperial)

3 #4 or 12 gage 1,0 1,0 2,5 1,5

4#81,01,02,51,5

5 #10 or 3/16" 1,0 1,0 2,5 1,5

6 1/4" 1,0 1,0 2,5 1,5

8 5/16" 1,0 1,0 2,5 2,0

10 7/16" 1,5 1,5 3,0 2,0

12 1/2" 2,0 2,0 3,0 2,5

Eff. diameter

Preferably under shielding gas Preferably with ceramic ferrule

Welding element with

conical face

Welding element with

conical or

plane face

*)

When welding with shielding gas, a 10% longer time is normally selected.

When welding alloyed steel, a 10% lower current is normally selected.

The given values apply to weldings in the welding position PA. The welding time shall be

reduced for welding in the welding position PC.

In the case of short cycle stud welding, the welding time is less than 100 ms. It depends not

only on the stud diameter, but also on the available current intensity (I[A] = min. 100 x Ø (mm)).

The welding time should be as short as possible in the case of welding without weld pool

protection.

Welding energy is only selected by welding time.

Further notes on

– welding elements

– prestress at installation (tie load) and torque

– material combinations

see appendix and operating manual of the according welding

gun.

5 Stud Welding Procedure

5.5 Determination of Welding Parameters

Loading...

Loading...