IT 1002 Order No BA 93-66-1206 Issue 03.11.08 53

5.10 Welding Elements

The stud welding unit must be suitable for welding the welding elements to be used.

Observe the instructions in the operating manuals.

Welding elements are mainly manufactured with the cold formed process.

We recommend the following standard welding elements (see appendix).

Use only welding elements of the same lot. Take particular care

not to mix-up different lots. Slightest variations in geometry of

the welding elements, especially of the ignition tip, require

modified settings of the welding process.

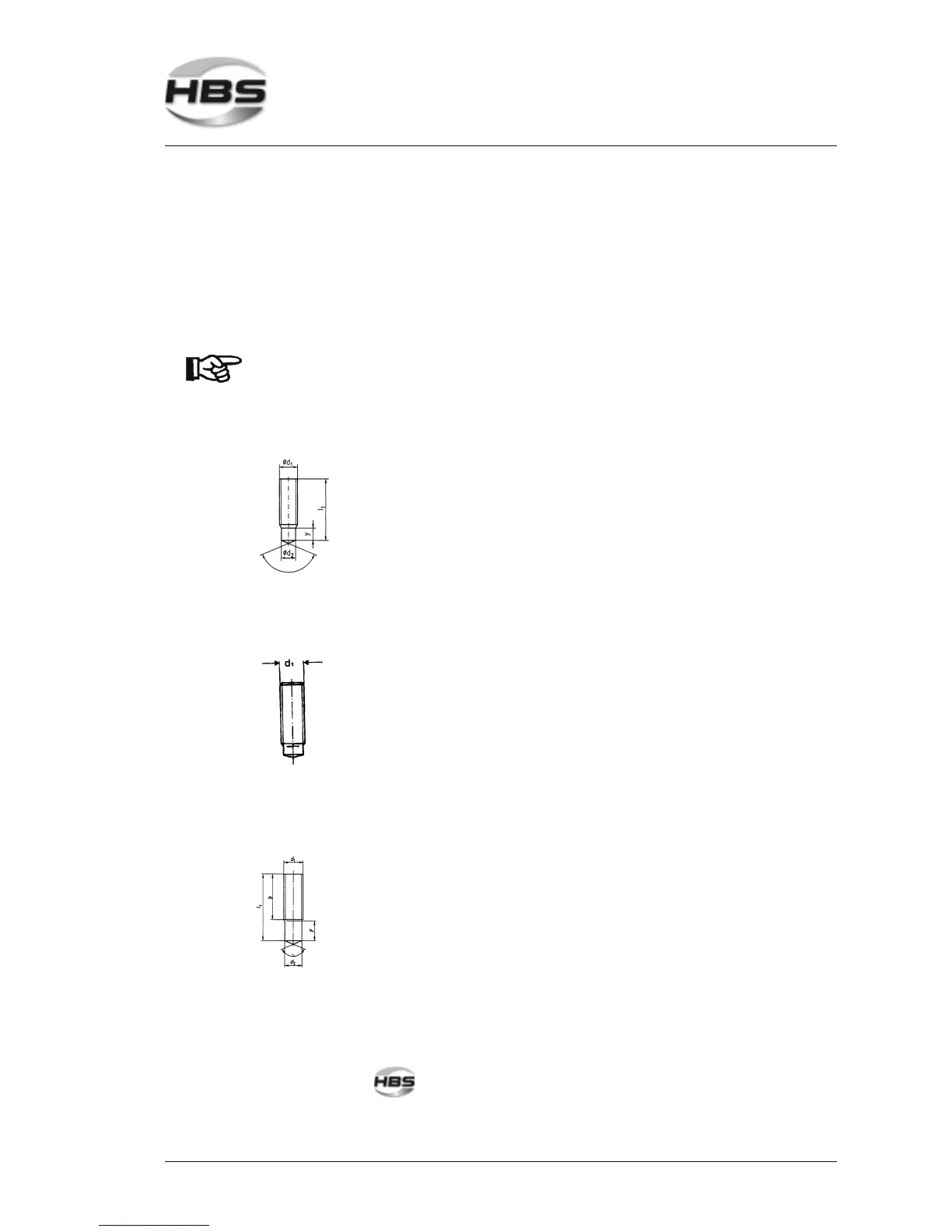

Threaded stud RD (MR) Diameter Length

Ceramic Shielding gas *)

M6 15-40 mm 83-50-006 83-51-006

M8 15-50 mm 83-50-008 83-51-008

M10 20-55 mm 83-50-010 83-51-010

M12 25-60 mm 83-50-012 83-51-012

M16 30-65 mm 83-50-016 83-51-016

Chuck

Materials: S235 / St37.3k (4.8) / 1.4301, 1.4303

Threaded stud DD (MD) Diameter Length

Ceramic Shielding gas *)

M6 15-30 mm 83-50-006 83-51-006

M8 15-50 mm 83-50-008 83-51-008

M10 20-55 mm 83-50-010 83-51-010

M12 25-60 mm 83-50-012 83-51-012

M16 30-65 mm 83-50-016 ---

Chuck

Materials: S235 / St37.3k (4.8) / 1.4301, 1.4303

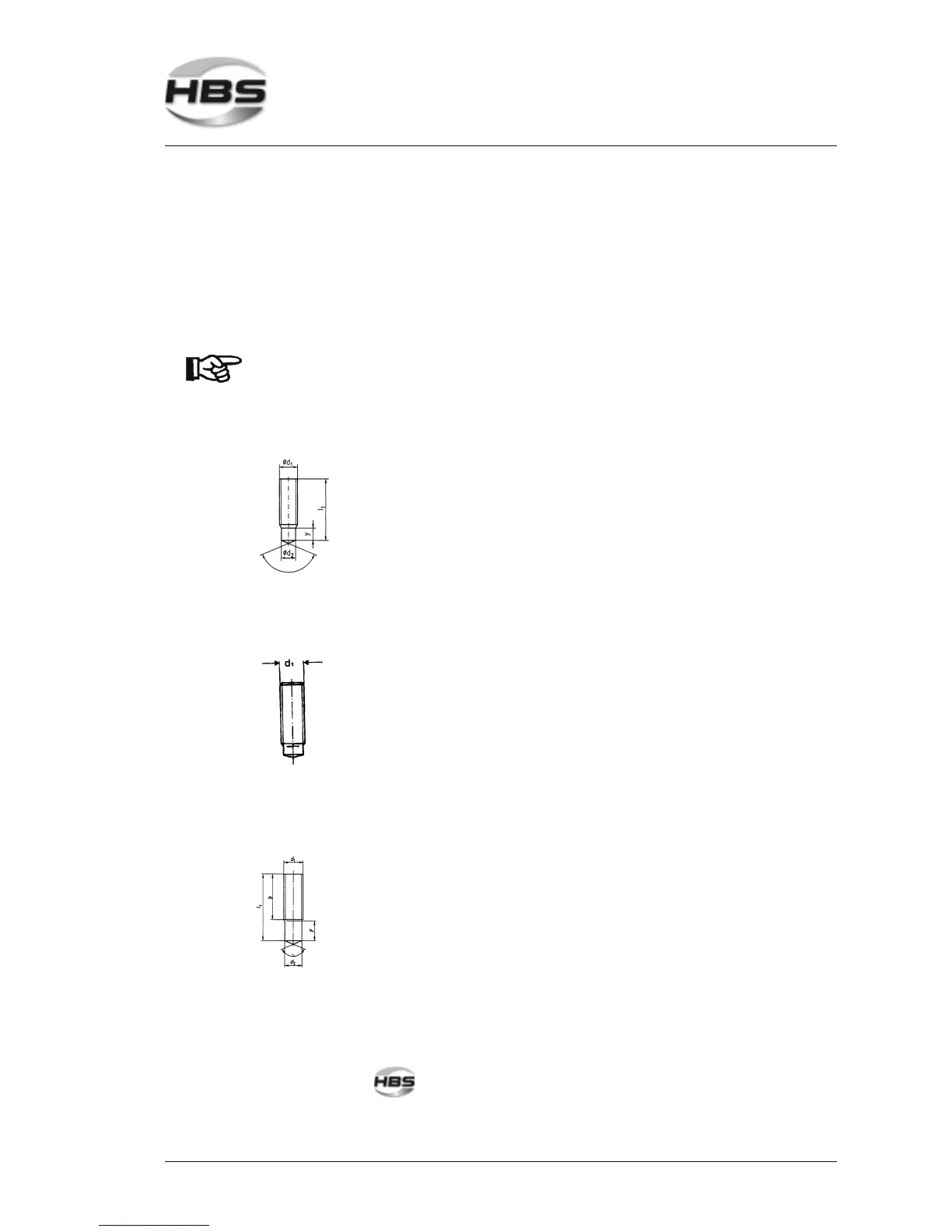

Threaded stud PD (MP) Diameter Length

Ceramic Shielding gas *)

M6 15-40 mm 83-50-006 83-51-006

M8 20-50 mm 83-50-008 83-51-008

M10 20-160 mm 83-50-010 83-51-010

M12 25-160 mm 83-50-012 83-51-012

M16 30-160 mm 83-50-016 ---

Chuck

Materials: S235 / St37.3k (4.8) / 1.4301, 1.4303

* Please use only welding elements without aluminum ball.

5 Stud Welding Procedure

5.10 Welding Elements

Loading...

Loading...