48 IT 1002 Order No BA 93-66-1206 Issue 03.11.08

5.8 Checking the Quality of the Weld

You can check the quality of the weld by means of a visual inspection and a bending

test.

See also actual standards in the appendix “Arc stud welding of

metallic materials“, in section irregularities and corrective

actions.

5.8.1 Visual Inspection

A visual inspection must be carried out with each welding element.

Shape, size, evenness, and color of the weld collar are assessed during a visual

inspection. The length of a welded element should be 2 to 3 mm shorter than before

welding.

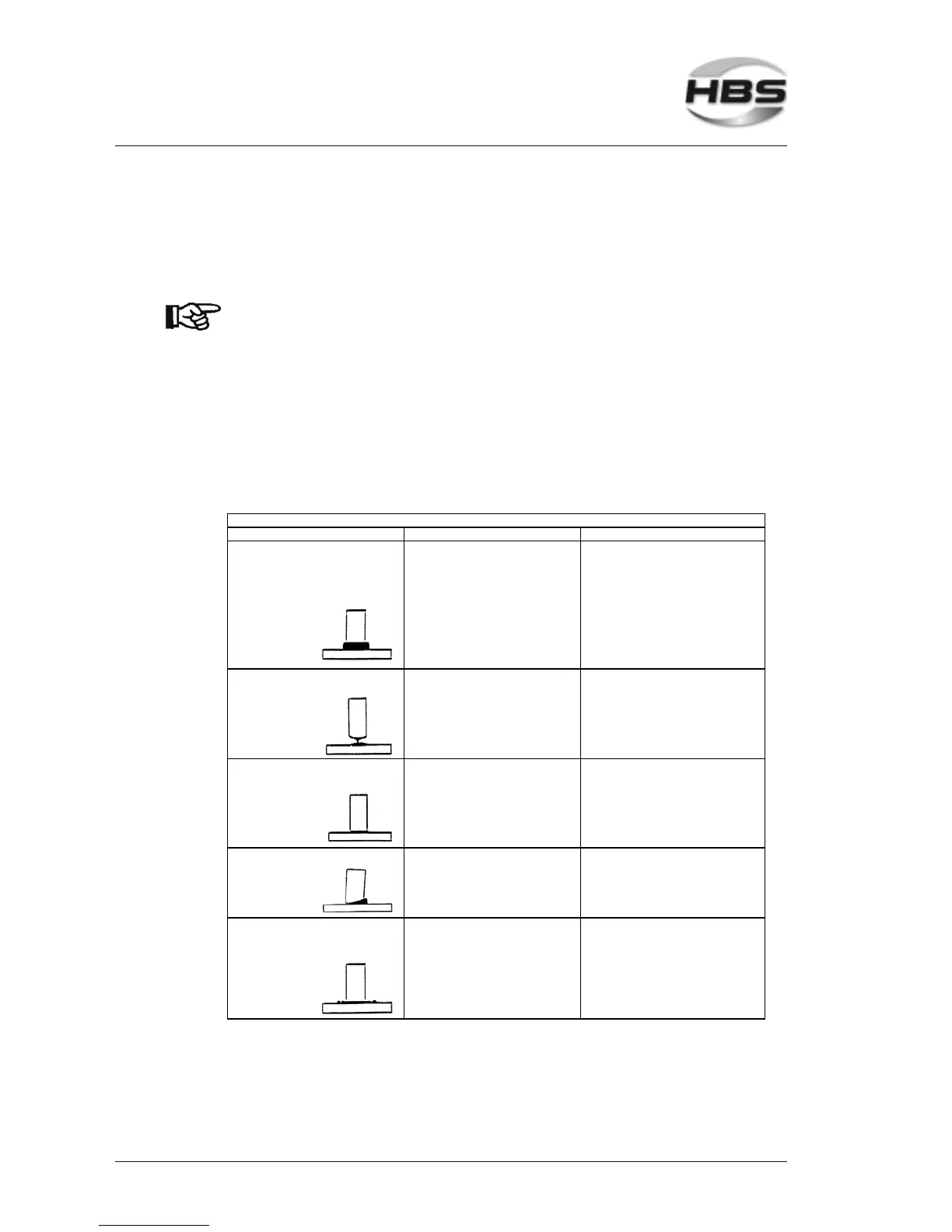

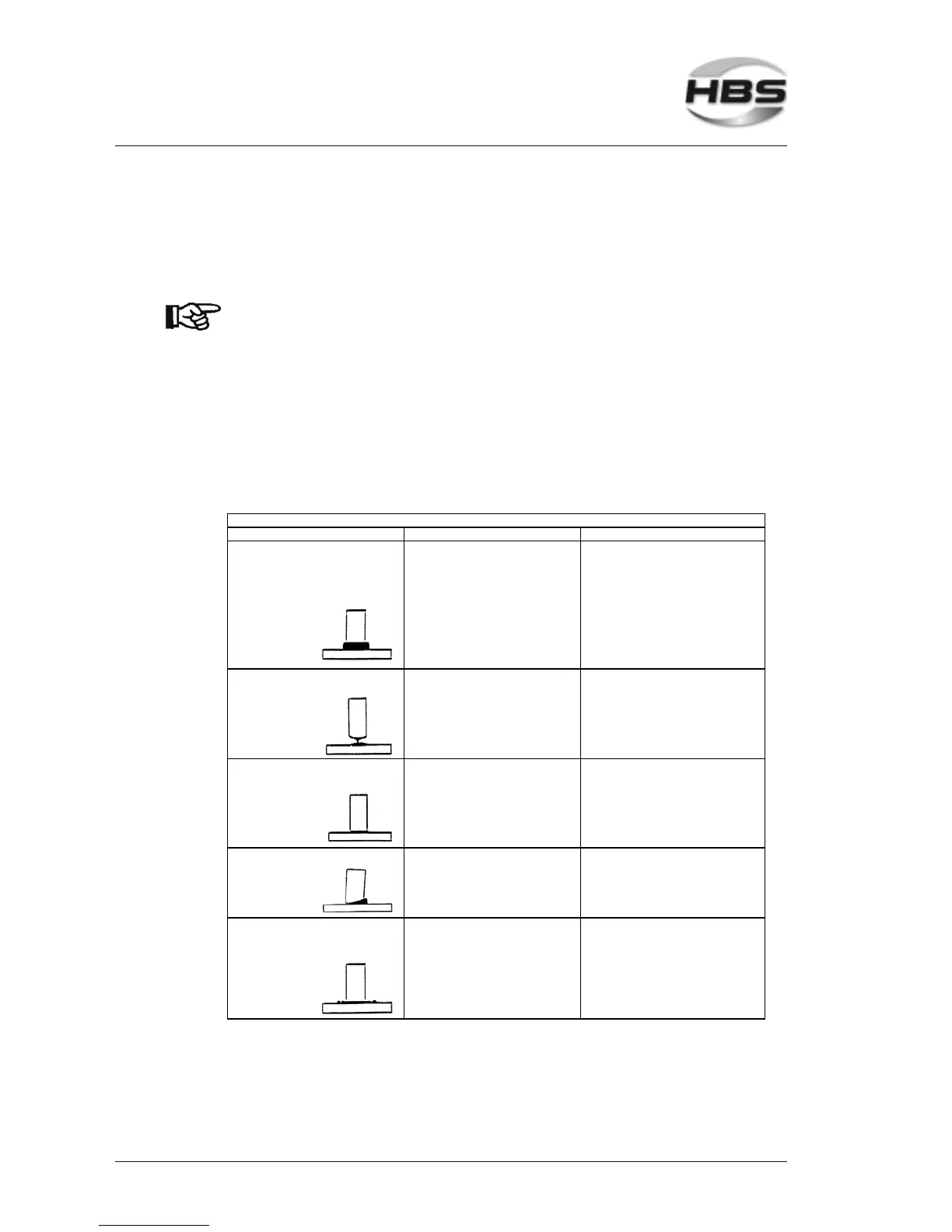

Condition Possible cause Corrective actions

Weld collar ev enly, shiny , and complete

Length of w elding element w ithin tolerance

af ter w elding

- Correct parameters - None

Contraction of w eld collar - Plunging depth or lift too low - Increase plunging depth, check lift and

centering of the ceramic ring

w elding element too long - Welding energy too high

- Ceramic ring not centered correctly

- Decrease current and/or time

- Check centering

Weakly developed, uneven w eld collar w ith

mat s u r f ac e

- Welding energy too low - Increase current and/or time

Welding element too long - Ceramic ring is humid - Rebake ceramic rings in a furnace

Single-sided w eld collar - Arc blow effect - See arc blow effect

Undercut - Ceramic ring not centered correctly - Check centering

Weld collar low , shiny surf ace w ith many

spatters

- Welding energy too high - Decrease current and/or time

Welding element too short - Plunging speed too high - Adjust plunging depth and/or damping factor

Visual Inspection

5 Stud Welding Procedure

5.8 Checking the Quality of the Weld

Loading...

Loading...