84 IT 1002 Order No BA 93-66-1206 Issue 03.11.08

Further Instructions

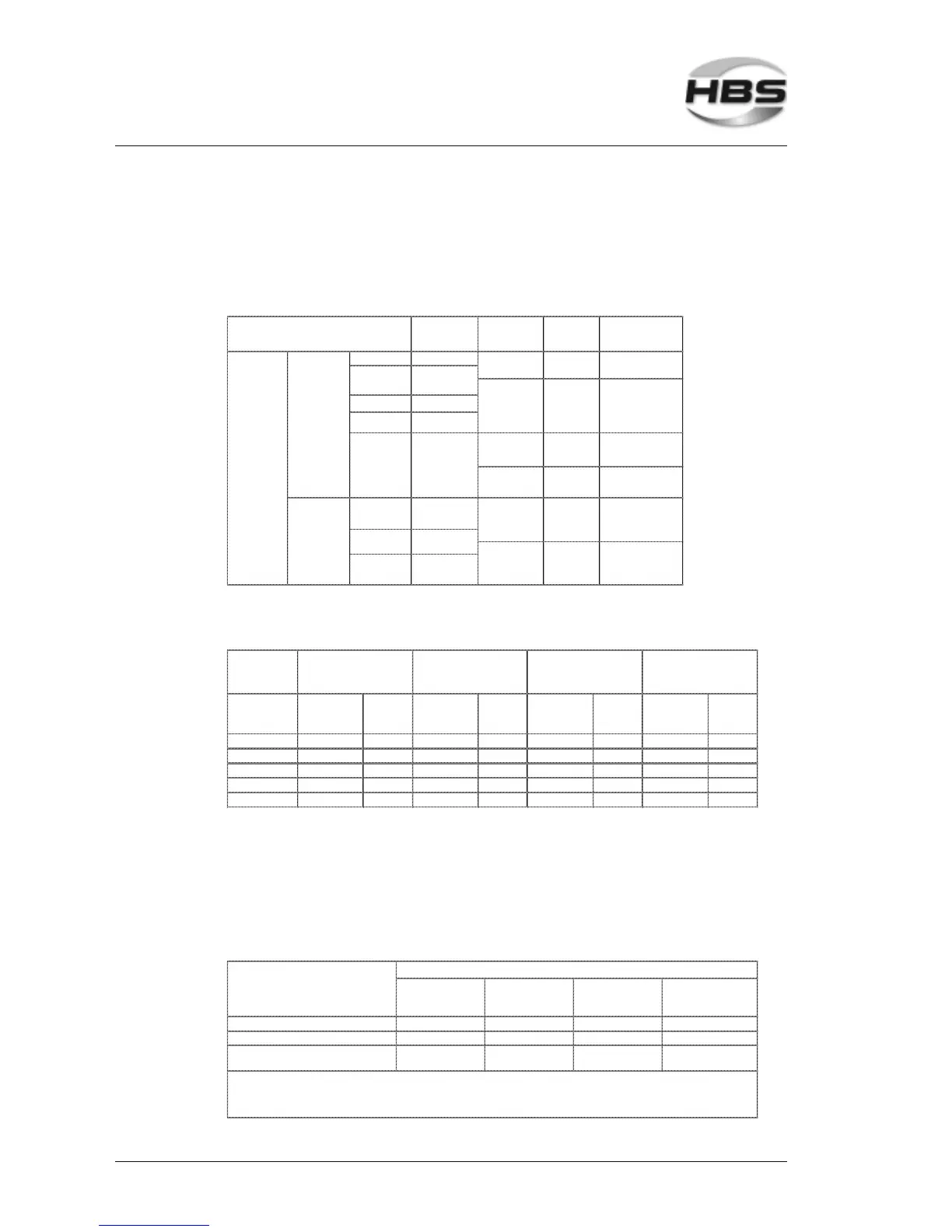

Welding elements, abbreviations, materials, standards, mechanical

properties to actual standards

Abbreviations f or

studs (ceramic

ferrules)

Material Norm

Mec hanic al

characteristics

Threaded stud PD (PF)

Pin w ith

internal thread

ID ( UF)

Mild steel

(S235J2G3

+ C450)

ISO/TR 15608

Rm

≥

400 N/mm

2

ReH

≥

235 N/mm

2

A5

≥

15%

1.4301/03

(A2-50)

EN 10088-1

Rm

≥

500 - 780 N/mm

2

Rp0,2

≥

350 N/mm

2

A5

≥

25%

Threaded stud

w ith flange

PS

Pin w ith internal

thread and

flange

IS

Mild steel (4.8

1)

) ISO 898-1 see ISO 898-1

Mild steel (4.8

1)

)

copper plated

1.4301/03

(A2-50)

EN IS O

3506-1

see ISO 3506-1

Stud types

Short cycle

welding

with

draw n arc

Draw n arc

welding

with

ceramic ferrule

(CF)

or shielding gas

(SG)

Head s tud

Stud

w elding

with

drawn arc

(DS)

Pi n

Pi n

w ith flange

UD (UF)

w ith reduced

shaft

RD (RF)

SD (UF)

US

1.4301/03

(A2-50)

EN IS O

3506-1

see ISO 3506-1

ISO 898-1 see ISO 898-1

Further materials on request

1)

weldable

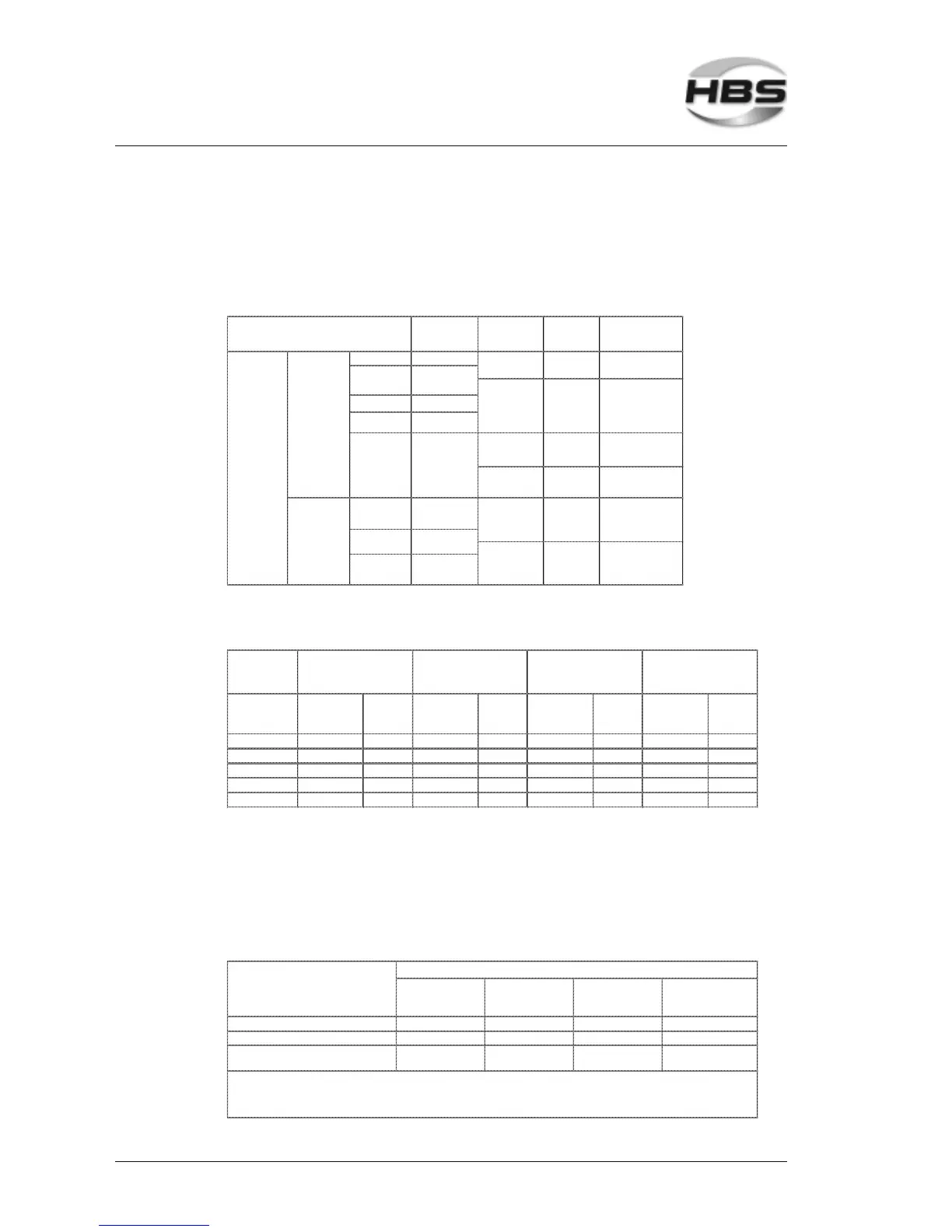

Prestress at installation (tie load) and torque

Threaded stud

Prestress at

installation

(kN)

Torque

(Nm)

Prestress at

installation

(kN)

Torque

(Nm)

Prestress at

installation

(kN)

Torque

(Nm)

Prestress at

installation

(kN)

Torque

(Nm)

M 6 4,3 6,1 2,7 3,8 2,2 3,1 3,2 4,5

M 8 8,0 15,0 4,9 9,5 4,0 7,5 6,0 11,0

M 10 13,0 30,0 7,8 19,0

M 12 19,0 53,0 12,0 33,0

M 16 35,0 135,0 22,0 82,0

Steel (4.8

1)

)

µ = 0,18

R

p0,2

= 340 N/mm

2

1.4301/03 (A2-50)

µ = 0,18

R

p0,2

= 210 N/mm

2

AlMg3 (F23)

µ = 0,18

R

p0,2

= 170 N/mm

2

CuZn37 (Ms63)

µ = 0,18

R

p0,2

= 250 N/mm

2

Values correspond with actual standards

1)

weldable

All given values are leads for minimum tensile strength and minimum torque of a weld without permanent deformation

of parts to be joined. Parts to be joined must have sufficient wall thickness. Values apply for cold rolled threaded studs

with standard thread without surface protection and without thread lubrication. Throughout the entire stud length, at

least the stressed cross section must be present. Values apply for indicated yield strengths.

Material combinations

according to the actual standards (select stud material in a way that material of the

same kind is welded).

ISO/TR 15608

Groups

1 and 2.1

ISO/TR 15608

Groups

2.2, 3 to 6

ISO/TR 15608

Groups

8 and 10

ISO/TR 15608

Groups

21 and 22

Steel (S235) 4.8

1)

16Mo3

abb --

1.4301/03, 1.4401/04, 1.4541,1.4571

b/a b a --

EN AW-AlMg3/EN AW-5754

EN AW-AlMg5/EN AW-5019

-- -- -- b

Exemplif ication of w elding suitability

-- non w e

Loading...

Loading...