Impact / Impact Pro / Impact Pro IR Operating Instructions

56

Using your Cl

2

Cartridge

Please ensure that the following points are noted when the cartridge is in service.

Always use PTFE tubing (maximum length of 500mm) and a flow rate of 1.

500ml/min when calibrating the Cl

2

channel.

Apply all gases to the port marked OUTLET (not INLET) on the Flow 2.

Housing.

With regard to the actual sensors fitted, please perform span calibrations 3.

on the sensors of the Impact Pro cartridge in the following order: Cl

2

, NH

3

,

H

2

S, CO, Flammable.

When performing a Span Calibration on the Cl4.

2

channel,it is good practice to

flow Cl

2

calibration span gas through connected tubing for a minimum of 15

minutes without the flow adapter fitted to the Impact Pro before attempting

a span calibration. Failure to do so may result in a false calibration of the

Cl

2

channel.

Do not apply Span Calibration gas to the Impact Pro for greater than 5 5.

minutes. Again failure to do so may result in a false calibration of the Cl

2

channel.

This cartridge is not suitable for pumped mode operation.6.

Due to the open nature of the Stainless Steel filter, there is a greater risk 7.

of water damage occurring to the instrument. Every attempt should be

made to keep the instrument dry.

Refer to the CAUTION given in 8. Section 1.1 of this manual for details on

recommended daily checks on your gas detector.

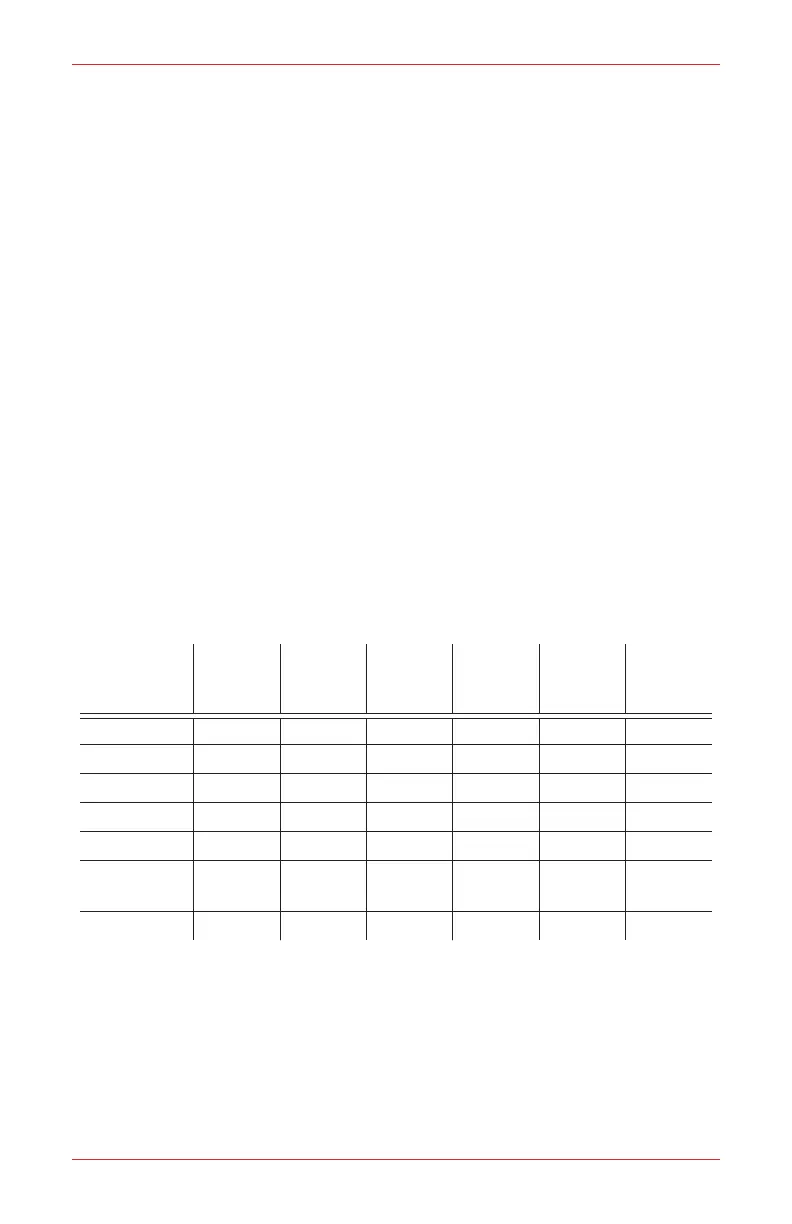

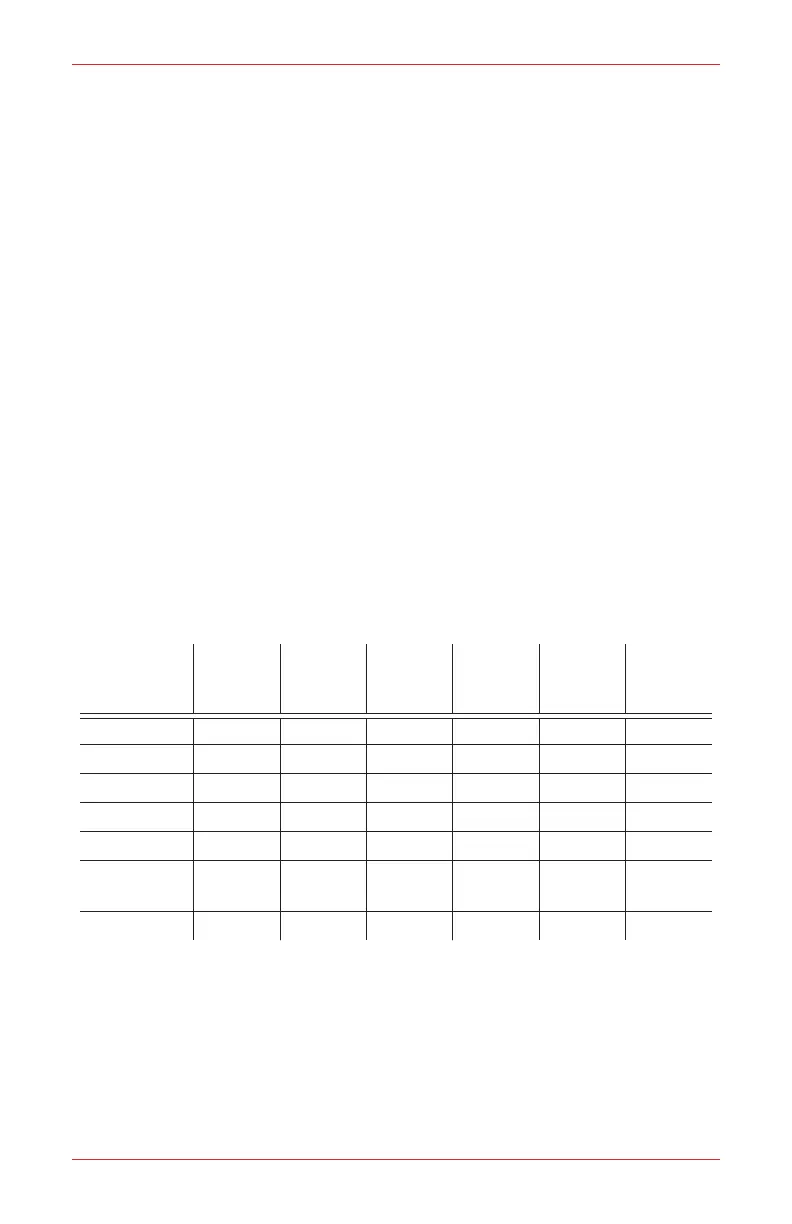

Applied Gas

Effect

on CO

Sensor

Effect

on H

2

S

Sensor

Effect

on CO

2

Sensor**

Effect

on Cl

2

Sensor

Effect

on NH

3

Sensor

Effect

on SO

2

Sensor

CO (100 ppm) 100 ppm 0 ppm 0% v/v 0 ppm 35 ppm 1 ppm

H

2

S (40 ppm) 0 ppm 40 ppm 0% v/v -25 ppm

1

50 ppm 1 ppm

CO

2

(0.5% v/v) 0 ppm 0 ppm 0.5% v/v 0 ppm 0 ppm TBA

Cl

2

(5 ppm) 0 ppm 0 ppm 0% v/v 5 ppm 0 ppm -2 ppm

1

NH

3

(50 ppm) 0 ppm 0 ppm 0% v/v -2 ppm

1

50 ppm TBA

Hydrogen

(1000 ppm)

200 ppm 0 ppm 0% v/v TBA 35 ppm TBA

SO

2

(10 ppm) 0 ppm 0 ppm 0% v/v 2 ppm 0 ppm 10 ppm

1

Reading displayed as -0ppm.

** Electrochemical CO

2

cell only

Loading...

Loading...