Model 7475A

width

is

increased until

the

comparator output inverts.

This

pulse width information is used by

the

microproc-

essor

to

regulate power to

the

motor drive circuits.

6-44.

MOTOR CURRENT SENSOR CIRCUIT

6-45.

Motor drive current flows through a

0.1

n resistor,

R7.

The

resulting voltage developed across

this

resistor

is

applied to

the

inverting

input

of

the

comparator ampli-

fier UlO (U9).

The

other

input

to

the

amplifier

is

fixed

at

approximately +0.315 V. Consequently,

if

motor current

reaches about 3.15

A,

the

comparator output

changes

from high to low, indicating excessive motor drive current.

6-46.

PEN

DOWN CIRCUIT

6-47.

When

the

microprocessor receives a

pen

down

instruction, a 15.6 kHz pulse signal

is

issued to

the

pen

down driver

UL

Because more power

is

required to acti-

vate

the

pen

solenoid

than

is

needed to hold

it

after

activation,

the

pulse

is

widened for a

short

period

of

time

to provide

this

extra

power.

The

duration of

the

pulse-

width-modulated signal

is

controlled

by

the

gate

array

U6

as

a function

of

the

18/26 Vdc unregulated supply

voltage.

An

air

damper slows

the

descent of

the

pen to

protect

the

pen tip.

6-48.

POWER

SUPPLIES

6-49.

Four

major voltages

are

generated

by

the

7475A

circuitry. Low

current

linear

supplies provide

the+

12 V

and

-5

V required for

the

servo IC's.

The

+5

V supply

provides

the

power for

the

remaining logic circuitry.

Regulation for

the+5

V

linear

supply

is

provided

by

U21

(U20).

The

fourth supply

is

the

unregulated 18/26 V

supplied to

the

main

drive motors

and

the

pen

carousel

drive motor.

The

18/26 V supply

can

be unregulated

because

of

the

voltage

sensing

and

servo

gain

adjust

cir-

cuitry described

in

earlier

paragraphs.

In

addition to

these supplies, a

-12

V source is provided on

the

RS-232-

C {Option 001) version.

This

source

is

used

in

conjunc-

tion

with

the

+ 12 V supply to operate

the

I/O

(input/

output) line drivers.

6-50. RECOMMENDED TEST EQUIPMENT

6-51.

Test

equipment

needed

to

maintain

the

7475A

is

listed

in

Table

6-2.

Models other

than

those listed

may

Section

VI

be used

if

their

specifications equal

or

exceed those

of

the

models listed.

6-52. TROUBLESHOOTING

6-53.

If

the

plotter does

not

operate properly,

make

sure

the

input/output

connector is seated correctly.

If

this

is

not

the

problem, remove

the

top

case

as

instructed

in

Top

Case

Removal,

and

make sure all cables

are

secure

in

their connectors.

6-54.

EXCHANGE

PRINTED

CIRCUIT

ASSEMBLY

6-55.

The

printed circuit assembly

is

available

on

an

exchange basis;

that

is, a factory-repaired

and

tested

assembly

may

be ordered

and

the

defective assembly

returned

for credit. Refer

to

Section

IV

for

ordering

instructions

and

the

exchange

part

number

for your par-

ticular assembly. Because

of

the

complexity of

the

cir-

cuits,

it

is

recommended

that

you replace

and

return

a

defective printed circuit assembly to Hewlett-Packard

rather

than

attempt

repair.

6-56.

DRIVE MOTORS AND

PEN

SOLENOID

6-57.

The

drive motor/encoder assemblies

and

the

pen

solenoid are

not

repairable. Motor

and

encoder cables

are replaceable.

The

motor cable (twisted pair)

is

PIN

07470-60016.

The

encoder (flat) cable

is

PIN

8128-4027.

I

WARNING

I

Maintenance

described

herein

is

per-

formed with power applied to

the

plot-

ter

and

the

top

case

removed.

Such

maintenance

should be performed only

by service-trained personnel who

are

aware

of

the

hazards

involved

(for

example, fire

and

electrical shock). Where

maintenance

can

be performed without

power applied,

the

line cord should be

disconnected.

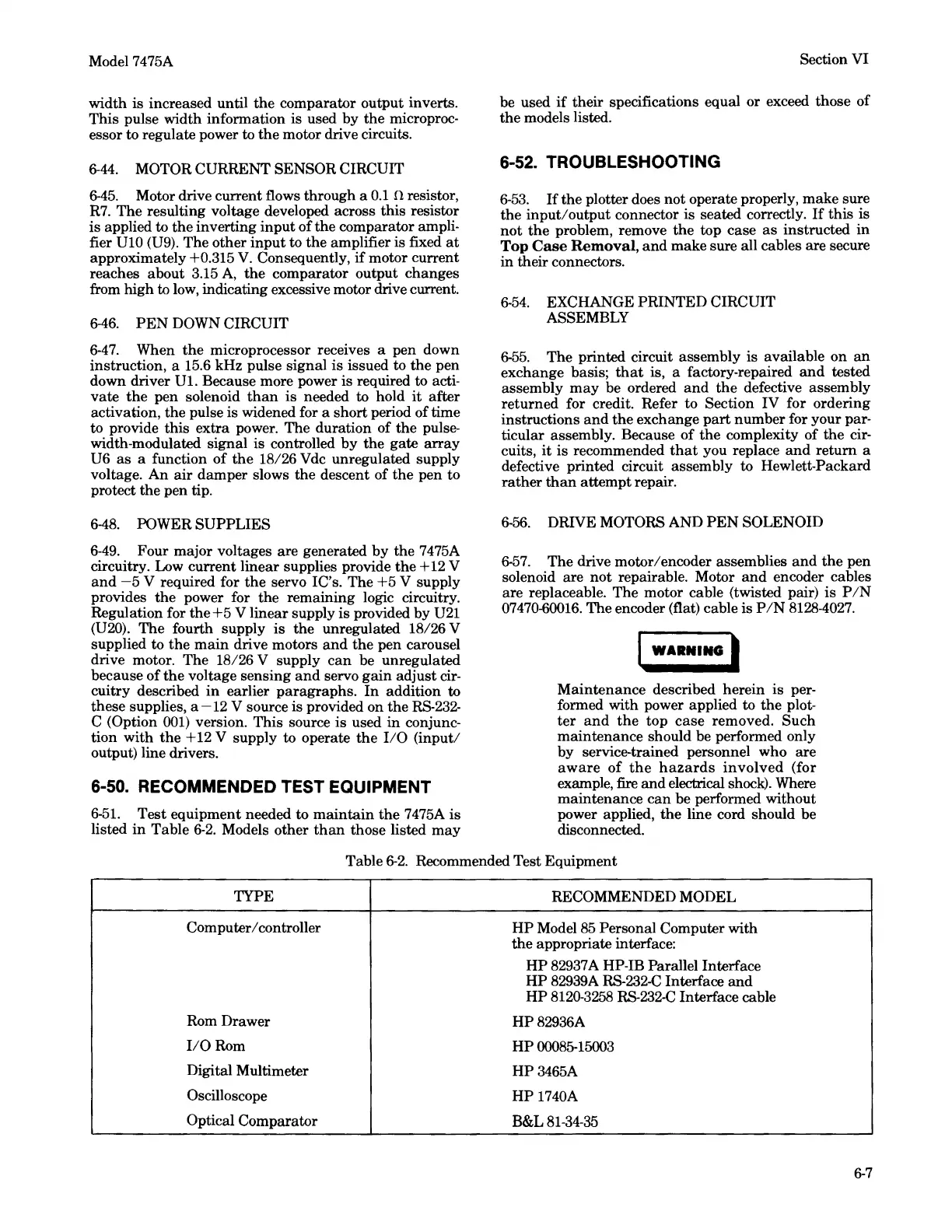

Table

6-2.

Recommended Test Equipment

TYPE

RECOMMENDED MODEL

Computer/

controller

HP

Model 85 Personal Computer with

the

appropriate interface:

HP

82937A HP-IB Parallel Interface

HP

82939A RS-232-C Interface

and

HP

8120-3258

RS-232-C

Interface cable

Rom Drawer

HP82936A

I/ORom

HP

00085-15003

Digital Multimeter

HP3465A

Oscilloscope

HP

1740A

Optical Comparator

B&L

81-34-35

6-7

Loading...

Loading...